Low-silver halogen free soldering paste

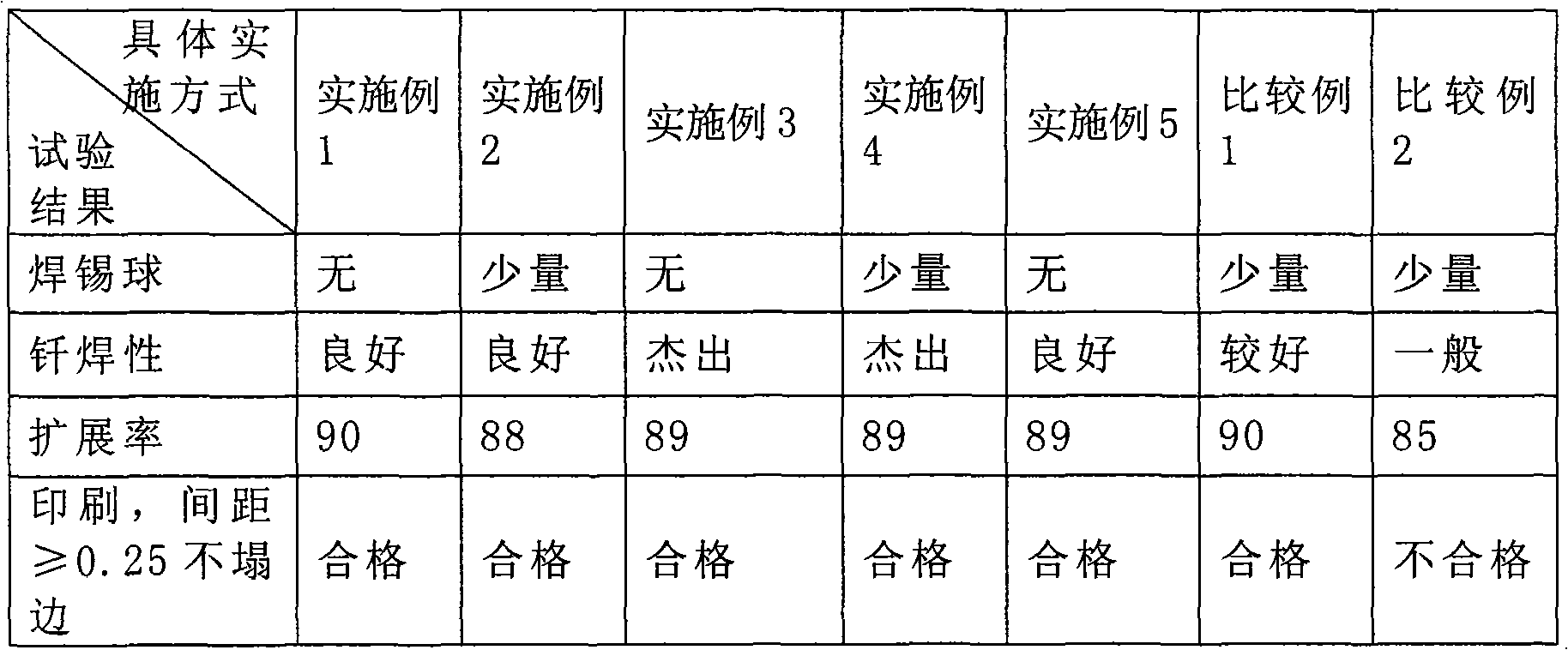

A technology of solder paste and halogen, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve problems such as not suitable for welding of fine-pitch components, not suitable for market demand, and easy collapse of solder paste, etc., to achieve Low cost, good welding performance, and less residue after welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

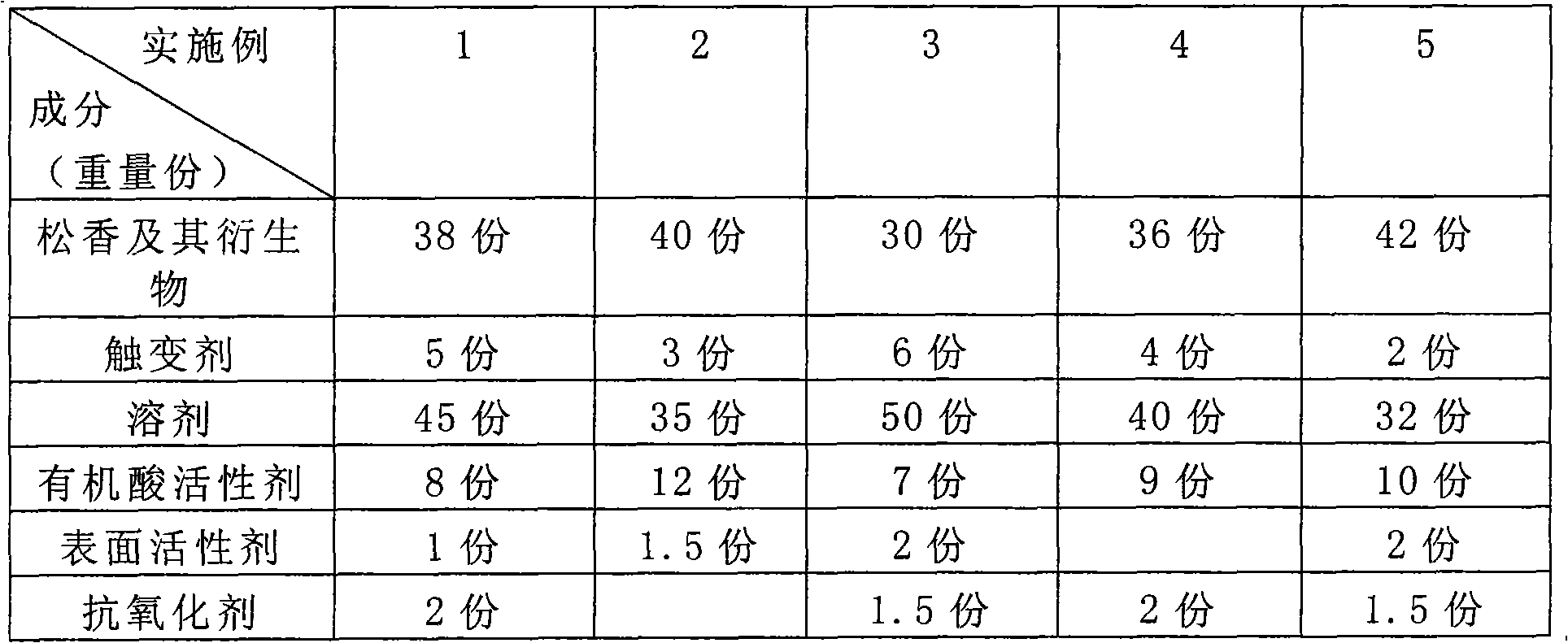

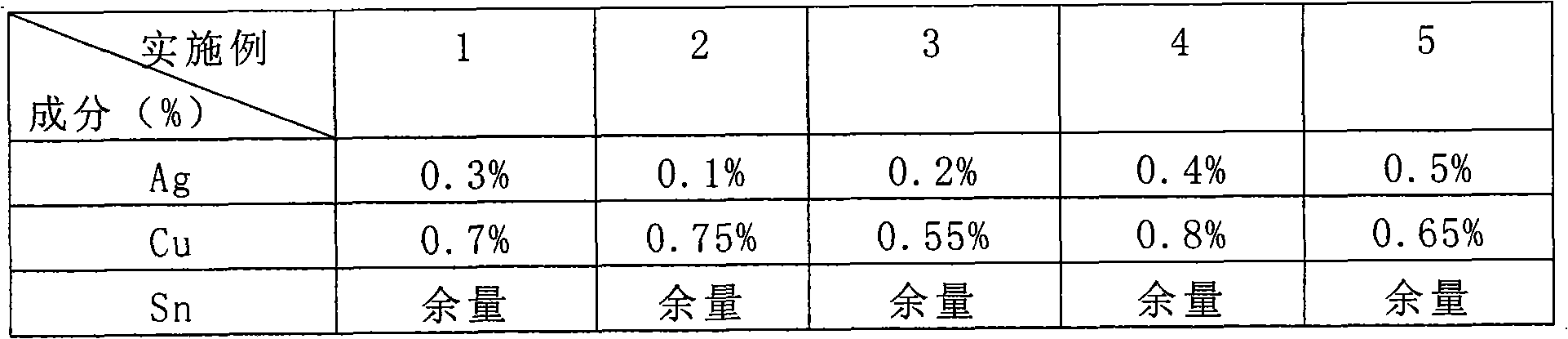

Embodiment 1

[0033] The preparation method of the low-silver and halogen-free solder paste described in Example 1 is as follows: Weigh the components of the solder paste according to the weight parts of Example 1 in Table 1, and combine rosin and its derivatives, organic acid activator, and surfactant , Solvent and antioxidant materials are sequentially added to the container for heating, stirring and dissolving at a temperature not higher than 100°C, and then cooling to room temperature. Add thixotropic agent, disperse to 70℃ at high speed, and then cool to room temperature to obtain flux paste.

[0034] Then, 10.5% by weight of the soldering paste and 89.5% by weight of the alloy solder powder are evenly stirred to obtain the low-silver and halogen-free solder paste described in Example 1.

Embodiment 2

[0035] The preparation method of the low-silver and halogen-free solder paste described in Example 2 is as follows: Weigh the components of the flux paste according to the weight parts of Example 2 in Table 1, and the rest of the process is the same as in Example 1, and will not be repeated to obtain the flux paste .

[0036] Then, 11.5% by weight of the soldering paste and 88.5% by weight of the alloy solder powder are evenly stirred to obtain the low-silver and halogen-free solder paste described in Example 2.

Embodiment 3

[0037] The preparation method of the low-silver and halogen-free solder paste described in Example 3 is as follows: Weigh the components of the soldering paste according to the weight parts of Example 3 in Table 1, and the rest of the process is the same as that of Example 1, and will not be repeated to obtain the soldering paste. .

[0038] Then, 9.5% by weight of the soldering paste and 90.5% by weight of the alloy solder powder are evenly stirred to obtain the low-silver and halogen-free solder paste described in Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com