Polymer modified asphalt and preparation method thereof

A technology of modifying asphalt and polymers, which is applied to building structures, building components, building insulation materials, etc., and can solve the problems of reduced storage stability of asphalt, increased production costs of asphalt, and substandard low-temperature ductility. Storage stability, viscosity reduction, aggregation prevention effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

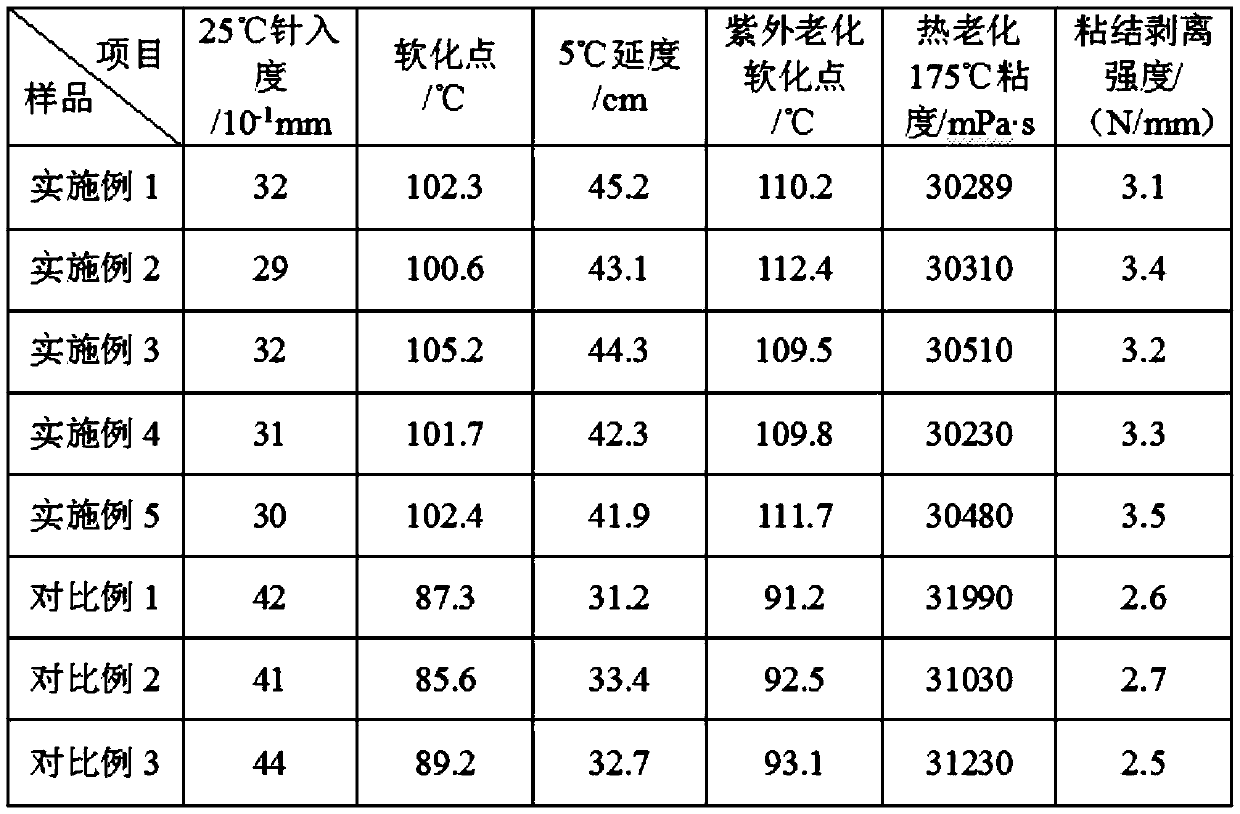

Examples

Embodiment 1

[0044] A polymer-modified asphalt comprising the following components by weight: 70 parts of road petroleum asphalt, 1 part of styrene-butadiene-styrene block copolymer, N-(2- 0.1 part of aminoethyl)-3-aminopropyltrimethoxysilane, 0.1 part of zinc diethyldithiocarbamate and 1 part of minus three-line extraction oil.

[0045] Adopt above-mentioned raw material to prepare a kind of polymer-modified asphalt, and the preparation method of this polymer-modified asphalt comprises the following steps:

[0046] (1) Weigh 70 parts of road petroleum asphalt and 1 part of styrene-butadiene-styrene block copolymer, and ultrasonically disperse 5min while stirring at 160° C. The ultrasonic frequency is 30KHz, and mix uniformly to obtain styrene-butylene Diene-styrene block copolymer - road petroleum asphalt mixture;

[0047] (2) Weigh 0.1 part of N-(2-aminoethyl)-3-aminopropyltrimethoxysilane, 0.1 part of zinc diethyldithiocarbamate and 1 part of minus three-line extraction oil, add step (...

Embodiment 2

[0049] A polymer-modified asphalt comprising the following components in parts by weight: 75 parts of coal tar pitch, 2 parts of styrene-isoprene-styrene block copolymer, aniline methyl trimethoxy 0.5 part of base silane, 0.5 part of zinc ethylphenyl dithiocarbamate and 2 parts of minus four-line extraction oil.

[0050] Adopt above-mentioned raw material to prepare a kind of polymer-modified asphalt, and the preparation method of this polymer-modified asphalt comprises the following steps:

[0051] (1) Weigh 75 parts of coal tar pitch and 2 parts of styrene-isoprene-styrene block copolymer, and ultrasonically disperse 6min while stirring at 170°C, and the ultrasonic frequency is 40KHz, and mix uniformly to obtain styrene-isoprene Pentadiene-styrene block copolymer-coal tar mixture;

[0052] (2) Weigh 0.5 part of aniline methyl trimethoxysilane, 0.5 part of zinc ethyl phenyl dithiocarbamate and 2 parts of minus four-line extraction oil, add the styrene-isoprene obtained in st...

Embodiment 3

[0054] A polymer-modified asphalt, the polymer-modified asphalt comprises the following components by weight: 80 parts of straight-run asphalt, 5 parts of styrene-ethylene-butylene-styrene block copolymer, N-aminoethyl 0.5 part of base-3-aminopropylmethyldimethoxysilane, 1 part of bispentamethylenethiuram tetrasulfide, and 3 parts of a mixture of minus three-line extraction oil and minus four-line extraction oil.

[0055] Adopt above-mentioned raw material to prepare a kind of polymer-modified asphalt, and the preparation method of this polymer-modified asphalt comprises the following steps:

[0056] (1) Weigh 80 parts of straight-run asphalt and 5 parts of styrene-ethylene-butylene-styrene block copolymer, and ultrasonically disperse 8min while stirring at 195° C., the ultrasonic frequency is 55KHz, and mix uniformly to obtain styrene- Ethylene-butylene-styrene block copolymer-straight-run asphalt mixture;

[0057] (2) Weigh 0.5 part of N-aminoethyl-3-aminopropylmethyldimeth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com