Method for preparing low-temperature cross-linked emulsified SBS pitch modifier

A low-temperature cross-linking and cross-linking agent technology, used in building thermal insulation materials, building components, buildings, etc., can solve the problems of reduced stability of modified asphalt, unrecoverable solvents, environmental pollution, etc., achieving less environmental pollution and improving production. environment, avoid the effect of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

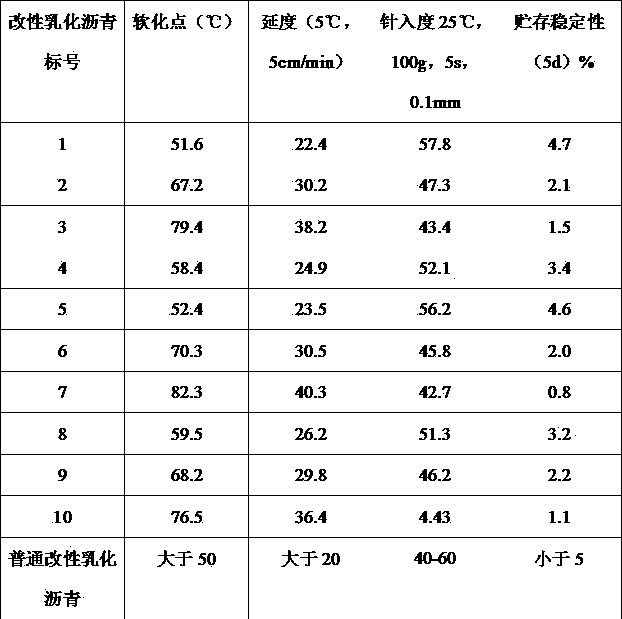

Examples

Embodiment 1

[0019] The preparation method of low-temperature crosslinking emulsified SBS asphalt modifier, comprises the following steps:

[0020] 1) Material preparation: by weight, including: 35kg of SBS particles, 0.4kg of crosslinking agent, 0.3kg of stabilizer, 2kg of cationic surfactant, 2kg of nonionic surfactant, 105kg of solvent, and 25kg of water. Among them, the crosslinking agent is dibenzoyl peroxide, the stabilizer is sodium carboxymethyl cellulose, the cationic surfactant is dodecyl dimethyl benzyl ammonium bromide, and the nonionic surfactant is fatty alcohol poly Oxyethylene ether, solvent is ethyl acetate.

[0021] 2) Prepare the sol: add the solvent into the reaction kettle at room temperature, then add the crosslinking agent and SBS particles respectively, stir at room temperature for 1 hour, and then take it out of the pot to make the SBS sol;

[0022] 3) Preparation of soap liquid: After mixing water and stabilizer, add cationic surfactant and nonionic surfactant at...

Embodiment 2

[0030] The preparation method of low-temperature crosslinking emulsified SBS asphalt modifier, comprises the following steps:

[0031] 1) Material preparation: by weight, including: SBS45kg, crosslinking agent 0.6kg, stabilizer 0.6kg, cationic surfactant 3.2kg, nonionic surfactant 2.7kg, solvent 130kg, water 30kg. Among them, the crosslinking agent is tert-butyl hydroperoxide, the stabilizer is sodium carboxymethyl cellulose, the cationic surfactant is tetradecyl dimethyl benzyl ammonium chloride, and the nonionic surfactant is alkylphenol Polyoxyethylene ether and solvent are solvent gasoline.

[0032] 2) Prepare the sol: add the solvent into the reaction kettle at room temperature, then add the cross-linking agent and SBS particles respectively, stir at room temperature for 2 hours, and then take it out of the pot to make the SBS sol;

[0033] 3) Preparation of soap liquid: After mixing water and stabilizer, add cationic surfactant and nonionic surfactant at 70°C and mix, a...

Embodiment 3

[0041] The preparation method of low-temperature crosslinking emulsified SBS asphalt modifier, comprises the following steps:

[0042] 1) Material preparation: by weight, including: SBS 50kg, crosslinking agent 0.8kg, stabilizer 0.9kg, cationic surfactant 4.5kg, nonionic surfactant 3.5kg, solvent 145kg, water 35kg. Wherein, the crosslinking agent is dicumyl peroxide, the stabilizer is sodium carboxymethyl cellulose, the cationic surfactant is cetyl dimethyl benzyl ammonium chloride, and the nonionic surfactant is The ratio is 1:1 mixed fatty alcohol polyoxyethylene ether and alkylphenol polyoxyethylene ether, and the solvent is dichloromethane.

[0043]2) Prepare the sol: add the solvent into the reaction kettle at room temperature, then add the crosslinking agent and SBS particles respectively, stir at room temperature for 3 hours, and then take it out of the pot to make the SBS sol;

[0044] 3) Preparation of soap liquid: After mixing water and stabilizer, add cationic surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com