Two-stage Design Method of Buton Rock Asphalt Modified Asphalt Mixture

A technology of asphalt mixture and asphalt modification, which is applied to the coagulation pavement, roads, roads and other directions of on-site paving, and can solve the problems of high internal pressure of tires and large traffic volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

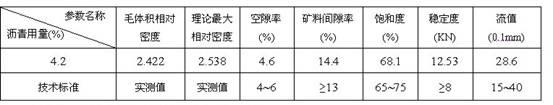

[0035] Example 1: Since the production mix ratio design of Buton rock asphalt modified asphalt mixture is the same as that of ordinary hot mix asphalt mixture, only the two-stage design process of the target mix ratio of Buton rock asphalt modified asphalt mixture is listed here.

[0036] 1. Raw material performance testing

[0037] 1) The base asphalt in the mix ratio design adopts No. 70 A-grade road petroleum asphalt, which complies with the technical requirements for this asphalt in the "Technical Specifications for Construction of Highway Asphalt Pavement" (JTG F40-2004). The modifier is natural Buton rock asphalt (BRA).

[0038] 2) Carry out the BRA raw material performance inspection, and the asphalt content is 24%, and other indicators meet the requirements of the BRA quality standard in Table 1.

[0039] 3) The aggregate limestone used in AC-20C coarse-grained coarse-grained dense-graded asphalt mixture includes: 10-20mm crushed stone, 10-19mm crushed stone, 10-15mm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com