Warm-mix bitumen mixture and preparation therof

A technology for warm mix asphalt and mixture, which is applied in the field of warm mix asphalt mixture and the preparation of warm mix asphalt mixture, achieves the effects of energy saving, stable storage and favorable promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Put the mineral material heated to 145°C into the mixing tank, then put in Shell AH-70# hot asphalt at 130°C, mix for 20 seconds, then put in the warm mix asphalt modifier through the observation window, and mix for 30 seconds to make The warm-mix asphalt mixture is obtained, and the weight proportions of the components are as follows: 2-5% of asphalt; 90-96% of mineral material; and 2-5% of warm-mix asphalt modifier.

[0024] Among them, the warm-mix asphalt modifier adopts the warm-mix asphalt modifier of the Sasobit brand of German Schumann-Sasol Company.

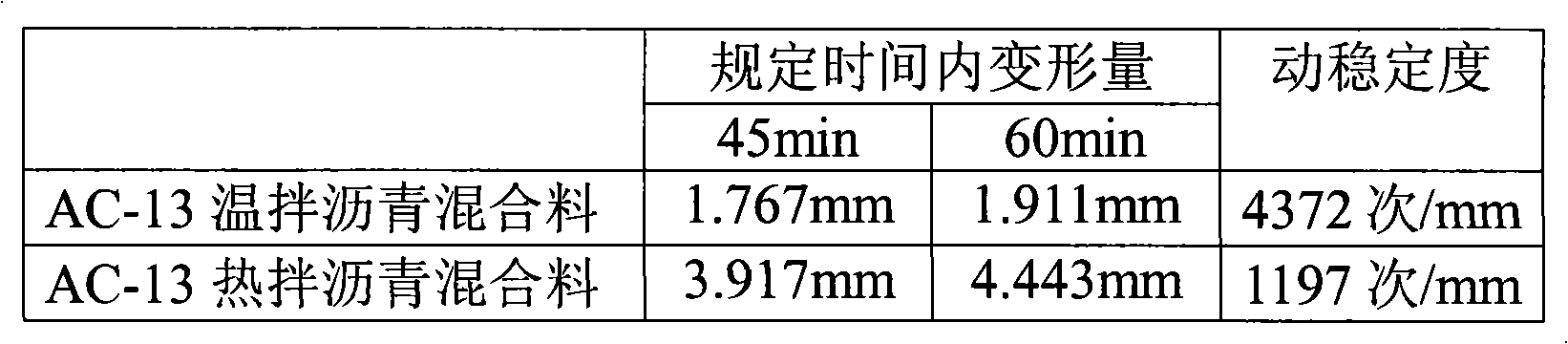

[0025] The comparison between the rutting dynamic stability index of warm-mix asphalt mixture and the rutting dynamic stability index of hot-mix asphalt mixture is as follows:

[0026]

[0027] It can be seen from the above table that the deformation of AC-13 warm mix asphalt mixture is 1.767mm at 45min and the deformation at 60min is 1.911mm, both of which are smaller than the deformation of AC-13 hot mix asph...

Embodiment 2

[0029] Use SK AH-70# asphalt to replace Shell AH-70# asphalt, and the rest of the raw materials, proportioning and preparation process are the same as in Example 1 to prepare warm mix asphalt mixture.

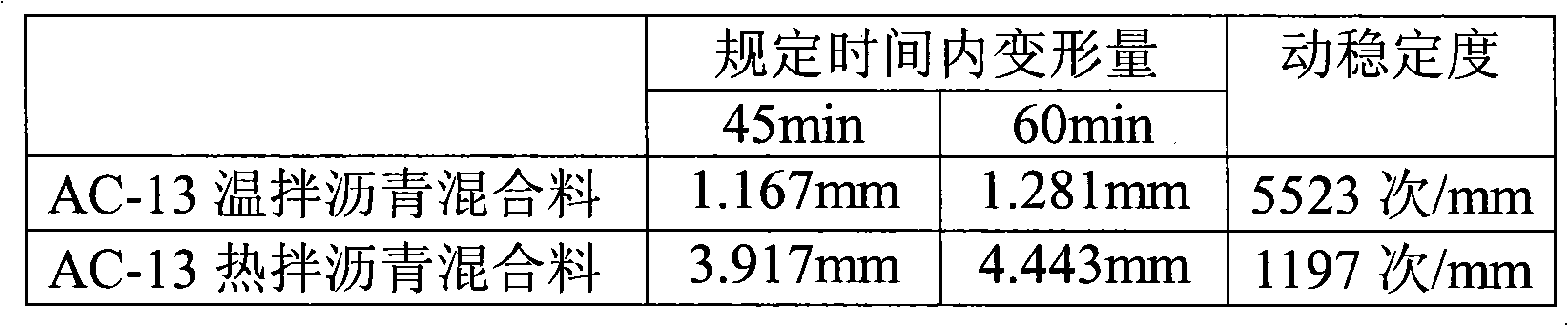

[0030] The comparison between the rutting dynamic stability index of warm-mix asphalt mixture and the rutting dynamic stability index of hot-mix asphalt mixture is as follows:

[0031]

[0032] It can be seen from the above table that the deformation of AC-13 warm mix asphalt mixture is 1.167mm in 45min and the deformation in 60min is 1.911mm, both of which are smaller than the deformation of AC-13 hot mix asphalt mixture in 45min of 3.917mm and the deformation in 60min 4.443mm; the rutting dynamic stability of AC-13 warm mix asphalt mixture is 5523 times / mm, which is much higher than the rutting dynamic stability of AC-13 hot mix asphalt mixture which is 1197 times / mm.

Embodiment 3

[0034] Esso AH-70# asphalt was used to replace Shell AH-70# asphalt, and the rest of the raw materials, proportioning and preparation process were the same as in Example 1 to prepare warm mix asphalt mixture.

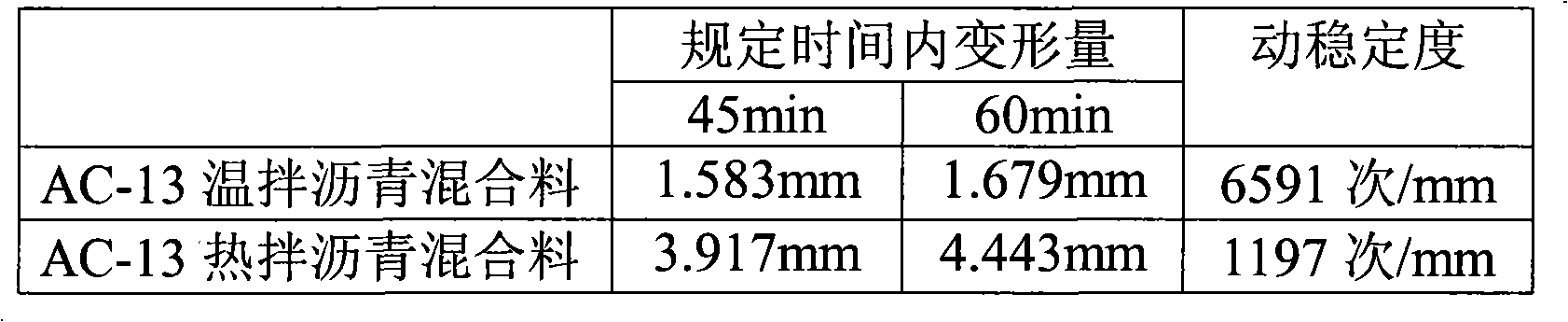

[0035] The comparison between the rutting dynamic stability index of warm-mix asphalt mixture and the rutting dynamic stability index of hot-mix asphalt mixture is as follows:

[0036]

[0037] It can be seen from the above table that the deformation of AC-13 warm mix asphalt mixture is 1.583mm in 45min and the deformation in 60min is 1.679mm, both of which are smaller than the deformation of AC-13 hot mix asphalt mixture in 45min of 3.917mm and the deformation in 60min 4.443mm; the rutting dynamic stability of AC-13 warm mix asphalt mixture is 6591 times / mm, which is much higher than the rutting dynamic stability of AC-13 hot mix asphalt mixture which is 1197 times / mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com