Anti-reflection film and production method therefor

An anti-reflection film and refractive index technology, applied in sputtering plating, ion implantation plating, coating, etc., can solve the problems of easy coloring of reflection hue, reduce visual reflectivity, etc., and achieve excellent mechanical properties and excellent reflection Characteristics, the effect of excellent reflection hue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

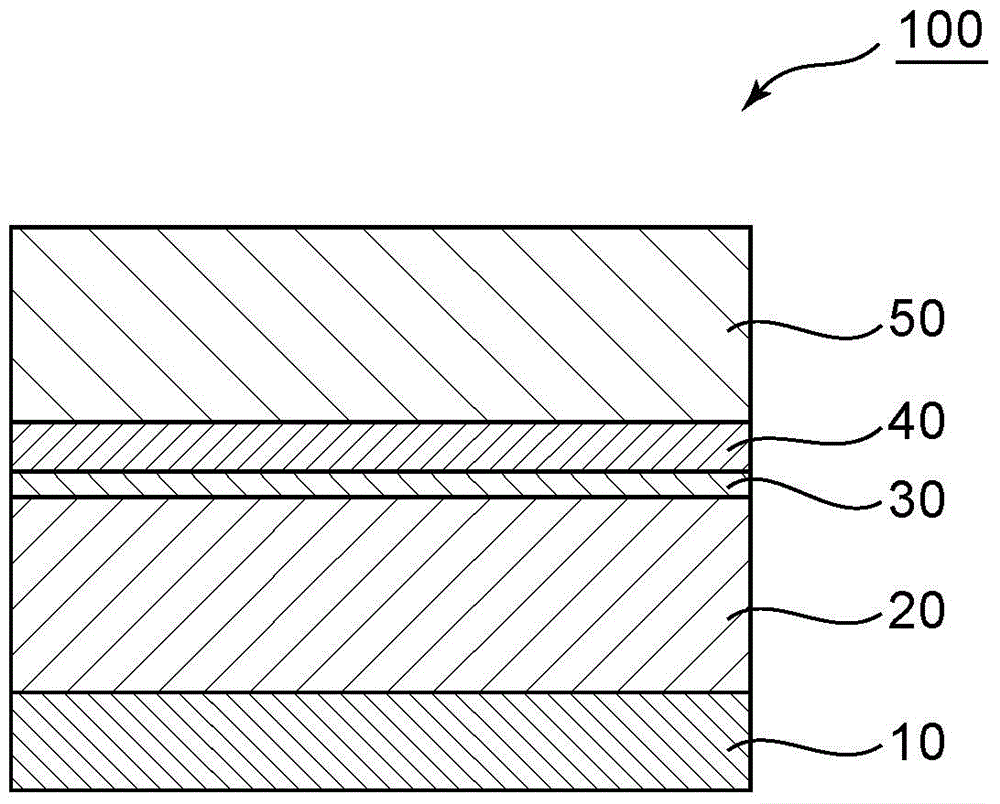

Image

Examples

Embodiment 1

[0092] A triacetyl cellulose (TAC) film with a hard coat layer (refractive index: 1.53) was used as a substrate. On the other hand, the following coating solution (composition for forming a medium refractive index layer) was prepared: zirconia particles (average particle diameter: 40 nm, a resin composition with a refractive index of 2.19) (manufactured by JSR Corporation, trade name "Opstar KZ series") was diluted to 3%. This coating solution was coated on the above-mentioned substrate using a bar coater, dried at 60°C for 1 minute, and then irradiated with ultraviolet rays with a cumulative light intensity of 300mJ to form a middle refractive index layer (refractive index: 1.68, thickness: 100nm ). Next, by sputtering Nb 2o 5 , thereby forming a high-refractive-index layer (refractive index: 2.33, thickness: 12 nm) on the medium-refractive-index layer. Furthermore, by sputtering SiO 2 , thereby forming a low-refractive-index layer (refractive index: 1.47, thickness: 110...

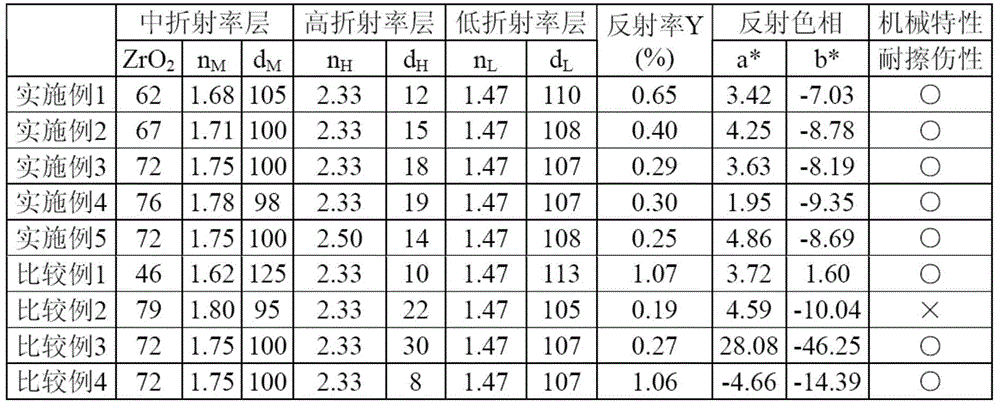

Embodiment 2~5 and comparative example 1~4

[0094] An antireflection film was prepared with the configuration shown in Table 1. The obtained antireflection film was subjected to the evaluations of (1) and (2) above. The results are shown in Table 1.

[0095] In addition, in each Example and a comparative example, the same base material was used. The refractive index of the middle refractive index layer was changed by changing the content of zirconia particles in the coating liquid as shown in Table 1. The refractive index of the high-index layer was obtained by sputtering TiO 2 (refractive index: 2.50) instead of Nb 2 o 5 And change. SiO is used for the refractive index of the low refractive index layer 2 and become constant. In addition, the thickness of the middle refractive index layer is changed by changing the coating thickness of the coating liquid. The thicknesses of other layers were changed by changing the sputtering thickness.

[0096] [Table 1]

[0097]

[0098] *ZrO 2 It is the content in all s...

Embodiment 6~7 and comparative example 5~7

[0100] An antireflection film was prepared with the configuration shown in Table 2. The obtained antireflection film was subjected to the evaluations of (1) and (2) above. The results are shown in Table 2.

[0101] In addition, in each Example and a comparative example, the same base material was used. The medium refractive index layer is formed using a resin composition containing titanium oxide particles (manufactured by Toyo Ink Co., Ltd., trade name "LIODURAS TYT series"), and the refractive index of the medium refractive index layer is determined by making the titanium oxide particles in the coating liquid content varies. The refractive index of the high refractive index layer uses Nb 2 o 5 and become constant. SiO is used for the refractive index of the low refractive index layer 2 and become constant. In addition, the thickness of the middle refractive index layer is changed by changing the coating thickness of the coating liquid. The thicknesses of other layers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com