Angstrom anti-blue lens and preparation method thereof

An anti-blue light and lens technology, applied in the field of optical lenses, can solve the problems of non-waterproof, fading, anti-blue light, and easy peeling of the lens, and achieve good anti-seawater corrosion effects, enhanced anti-seawater effects, and improved mechanical strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

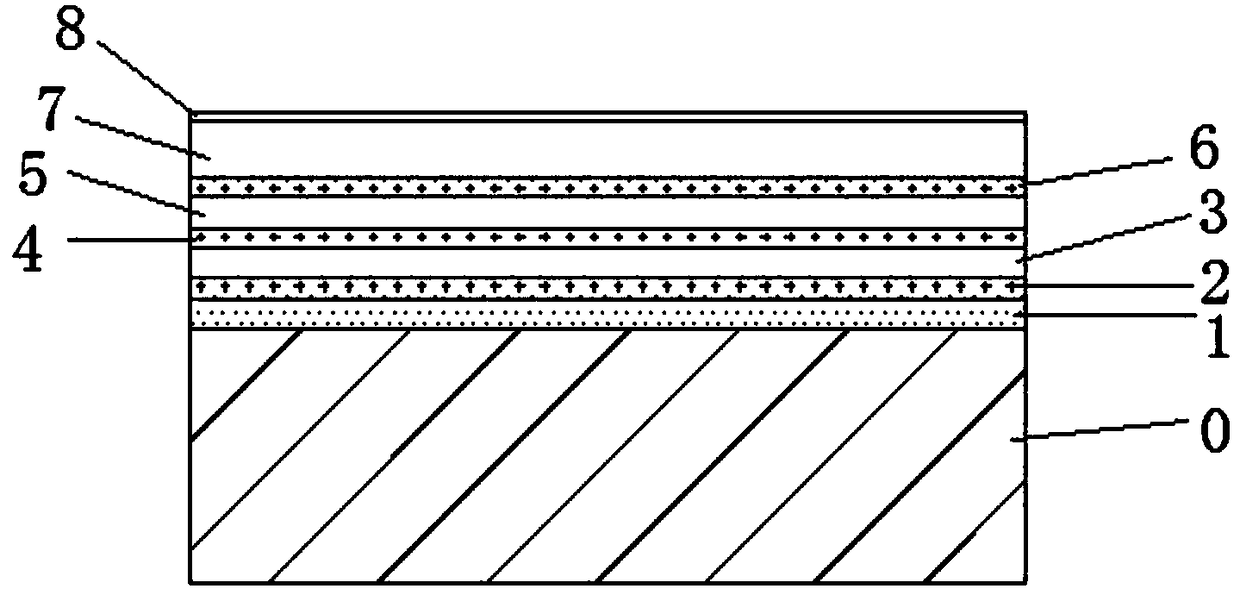

[0030] see figure 1 , an angstrom anti-blue light lens, comprising a base 0, a primer layer 1, a high refractive index layer 2, a low refractive index layer 3, a high refractive index layer 4, a low refractive index layer 5, a high refractive index layer 6, a low refractive index layer Layer 7 and protective layer 8, the thickness of each layer from bottom layer 1 to protective layer 8 is as follows: 800 angstrom, 500 angstrom, 800 angstrom, 500 angstrom, 800 angstrom, 500 angstrom, 1500 angstrom, 150 Angstrom, the high refractive index layer 2, the low refractive index layer 3, the high refractive index layer 4, the low refractive index layer 5, the high refractive index layer 6 and the low refractive index layer 7 constitute a composite film layer.

[0031] Among them, the substrate 0 is glass, the primer layer 1, the low refractive index layer 3, the low refractive index layer 5, and the low refractive index layer 7 are vacuum coating materials L5, the high refractive index...

Embodiment 2

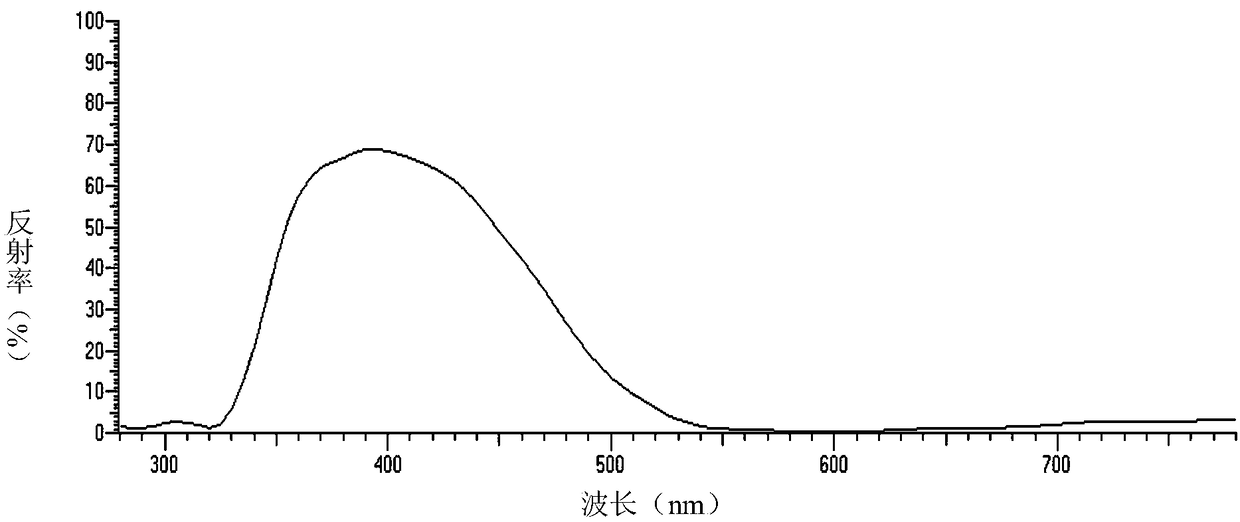

[0038] The lens obtained in Example 1 is detected by Japanese HITACHI spectrophotometer U3900H spectral reflectance, and its spectral reflectance curve is shown in figure 2 , see Table 1 for relevant data.

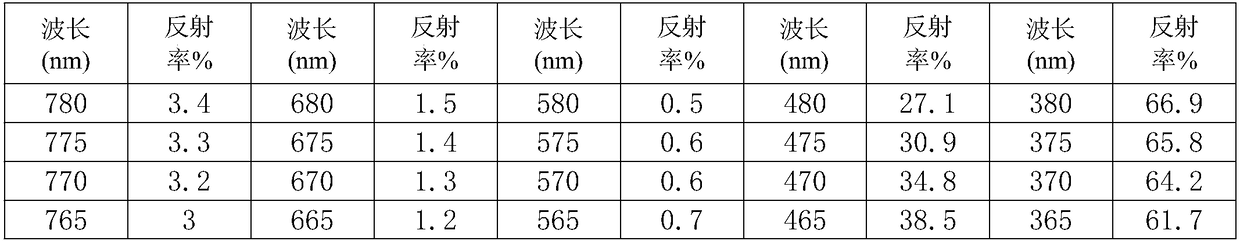

[0039] Table 1 Lens Spectral Reflectance Test Result Table

[0040]

[0041]

[0042]As can be seen from Table 1, the lens prepared by the present invention has a better reflective effect on light with a wavelength of 340-500nm, especially blue light with a wavelength of 400-480nm. The average reflectance is 52.5%, and the lowest point exceeds 27%. The highest reflectivity reaches 68.4%, which has a good anti-blue light effect.

Embodiment 3

[0044] An angstrom anti-blue light lens, comprising a base 0, a primer layer 1, a high refractive index layer 2, a low refractive index layer 3, a high refractive index layer 4, a low refractive index layer 5, a high refractive index layer 6, and a low refractive index layer 7 and protective layer 8, the thickness of each layer from primer 1 to protective layer 8 is as follows: 700 angstrom, 500 angstrom, 800 angstrom, 500 angstrom, 800 angstrom, 500 angstrom, 1600 angstrom, 50 angstrom m, the high refractive index layer 2, the low refractive index layer 3, the high refractive index layer 4, the low refractive index layer 5, the high refractive index layer 6 and the low refractive index layer 7 constitute a composite film layer.

[0045] Among them, the substrate 0 is an acrylic AC substrate, the primer layer 1, the low refractive index layer 3, the low refractive index layer 5, and the low refractive index layer 7 are silicon dioxide, the high refractive index layer 2, the hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com