ZnSe infrared anti-reflection film and method for producing the same

A technology of infrared anti-reflection coating and anti-reflection coating, which is applied in the direction of ion implantation plating, coating, instrument, etc., to achieve ideal anti-reflection effect, small mutual restraint and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

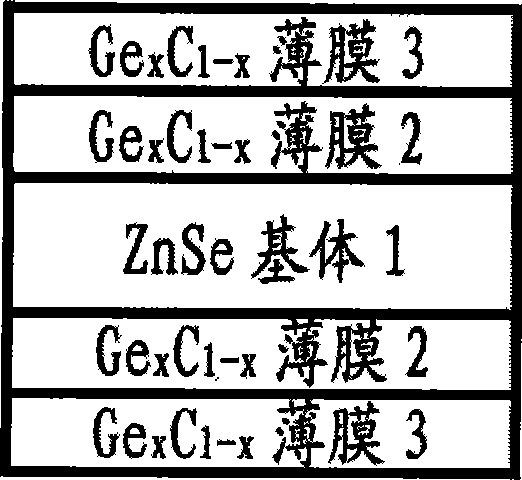

[0017] Embodiment 1 The structure of double-layer anti-reflection film system

[0018] Lambda of the present invention 0 / 4~λ 0 / 4 The structure of the double-layer antireflection protective film system is as follows: figure 1 shown.

[0019] The refractive index of ZnSe is n 1 =2.4~2.58, the Ge that can be obtained in our experiment x C 1-x The refractive index of the film can be changed in a large range (2.0-4), so that, according to the design requirements, the Ge film with the required refractive index can be prepared x C 1-x film. First deposit a layer of high refractive index film on the ZnSe substrate (1), and its optical thickness is λ 0 / 4, the refractive index is n 2 , then the refractive index of the combined system of film and substrate is Y=n 2 2 / n 1 to be equivalent, when n 2 >n 1 when Y>n 1 . Then deposit a layer of optical thickness λ 0 / 4 low refractive index n 3 film, make n 3 is approximately equal to , a good anti-reflection effect can...

Embodiment 2

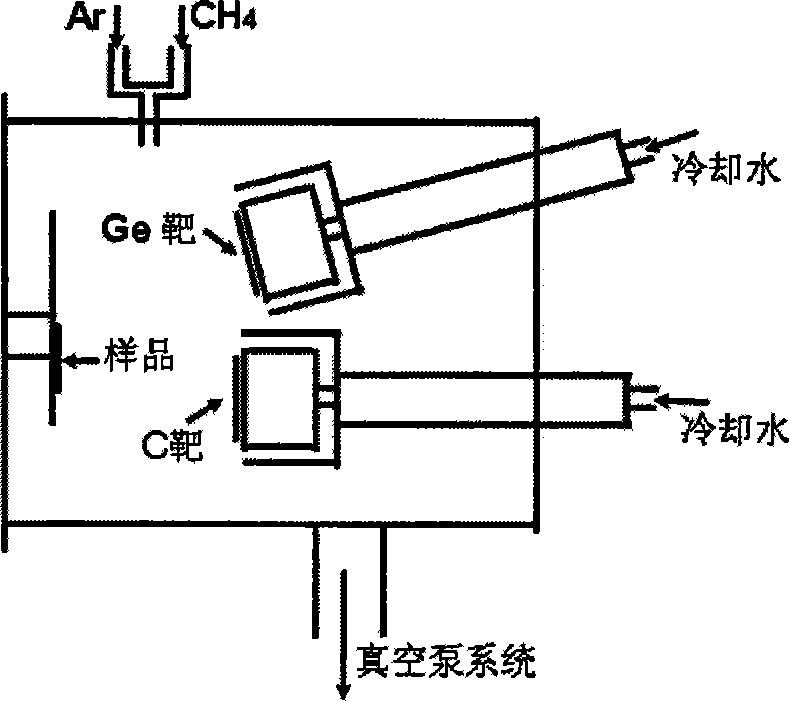

[0020] Embodiment 2 The preparation method of the ZnSe infrared anti-reflection film of the present invention

[0021] ZnSe infrared anti-reflection film prepared by intermediate frequency and DC magnetron sputtering deposition method with double targets, with CH 4 As the discharge gas, the mixed gas of Ar and Ar is respectively controlled by the needle valve and passed into the vacuum chamber in a certain proportion. The pressure of the vacuum chamber is 0.5-2Pa. After glow discharge, CH 4 The positive ions generated by the ionization of Ar and bombard the target source under the action of the electric field, and the sputtered Ge and C atoms or ions and CH 4 The hydrocarbon plasma generated by the decomposition undergoes a chemical reaction, and finally Ge is generated on the ZnSe substrate. x C 1-x film. In order to ensure the bonding force between the deposited film and the substrate, the ZnSe substrate needs to be pre-treated before the experiment, such as polishing an...

Embodiment 3

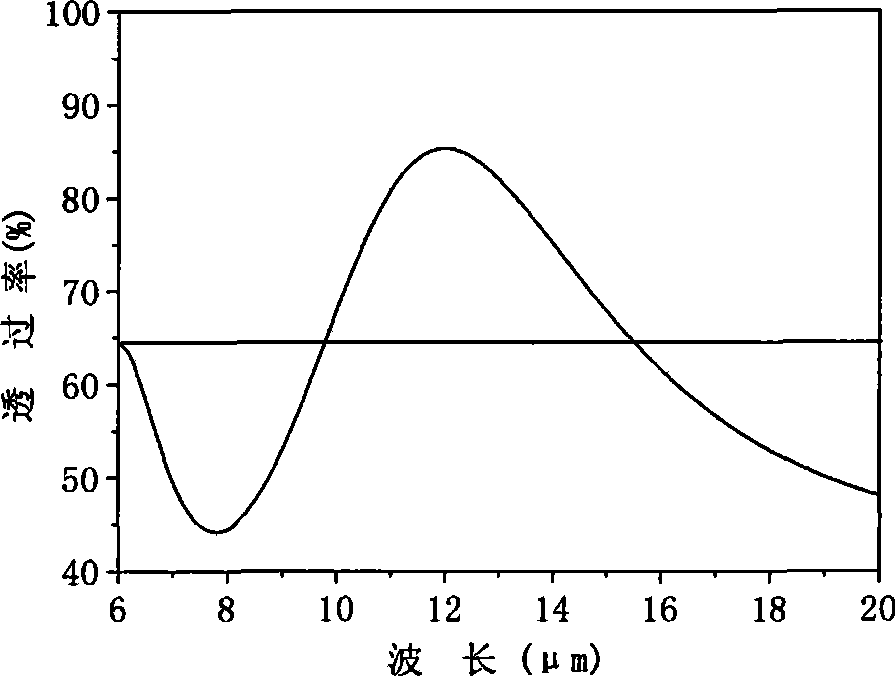

[0023] Example 3 Preparation method example

[0024] Taking the central wavelength of 10 μm as an example, a double-layer infrared anti-reflection coating system deposited on both sides.

[0025] Technological process is with embodiment 2. Using ZnSe as the substrate, depositing Ge x C 1-x Thin films of materials, intermediate frequency sputtering Ge targets, DC sputtering C targets, key process conditions for preparing double-layer films:

[0026] When depositing the first layer of high refractive index film (2) on the ZnSe substrate: CH 4 / (Ar+CH 4 ) with a voltage division ratio of 1:5; the intermediate frequency frequency is 40kHz, the voltage is 400V, and the current is 250mA; the pulse bias voltage is -80V, and the duty ratio is 80%; the deposition time is 20 minutes.

[0027] When depositing the second layer of low refractive index film (3) on the ZnSe substrate: CH 4 / (Ar+CH 4 ) with a voltage division ratio of 1:4; the intermediate frequency of the sputtering G...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com