Anti-reflection coating for ultra-wide-angle hemispherical lens and coating method thereof

A technology of hemispherical lens and anti-reflection coating, which is applied in the field of ultra-wide-angle hemispherical lens anti-reflection coating and its coating. It can solve the problems of uneven thickness of the center and edge of the lens, and the inability of the anti-reflection coating to achieve anti-reflection, so as to reduce reflection. efficiency, eliminate the risk of film cracking, and solve the effect of stress on the film layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

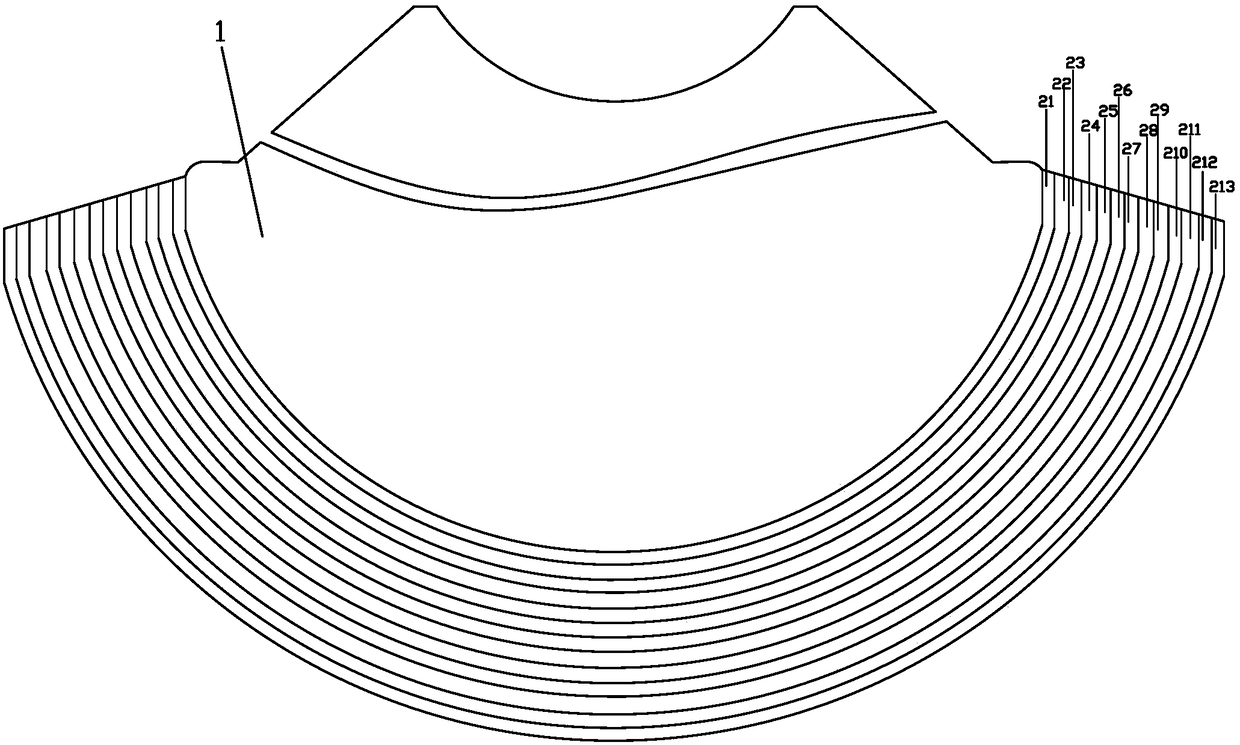

[0044] An anti-reflection coating for an ultra-wide-angle hemispherical lens, the anti-reflection coating 2 is composed of 13 layers of coatings coated on the lens body 1, wherein the 13 layers of coatings are in order from near to far from the lens body: First SiO 2 Film layer 21, the first TiO 2 Film layer 22, the second SiO 2 Film layer 23, the second TiO 2 Film layer 24, the third SiO 2 Film layer 25, the third TiO 2 Film layer 26, the fourth SiO 2 Film layer 27, the fourth TiO 2 Film layer 28, the fifth SiO 2 Film layer 29, the fifth TiO 2 Film layer 210, the sixth SiO 2 Film layer 211, the sixth TiO 2 Film layer 212 and MgF 2 film layer 213 .

[0045] The 13 film layers of the present invention are the minimum number of layers to achieve the effect of the present invention, but the thickness is difficult to control if the number of layers is too many, and it is not convenient for batch production.

[0046] The first SiO 2 The thickness of the film layer 21 i...

Embodiment 1

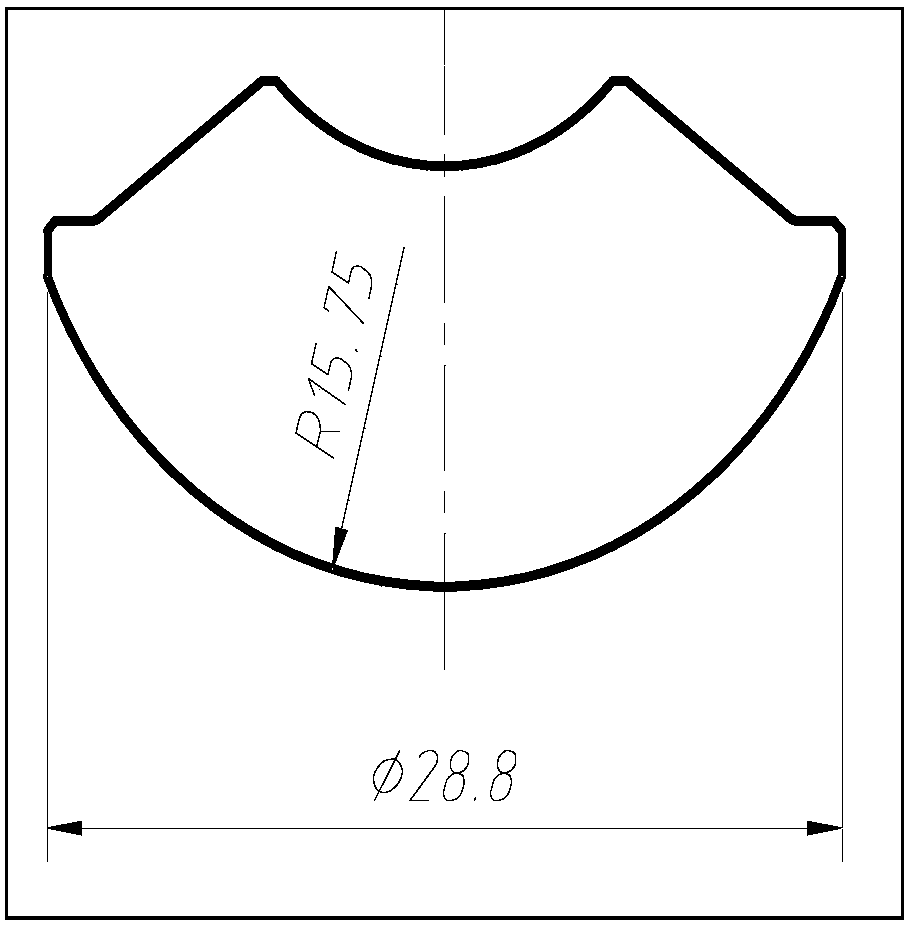

[0062] like figure 1 , the super wide-angle hemispherical lens has a convex surface curvature of 15.75mm, an aperture of 28.8mm, spectral index requirements: Rabs<0.5%@420-700, and the lens base material is ZF13.

[0063] A method for preparing an antireflection coating for an ultra-wide-angle hemispherical lens, comprising the following steps:

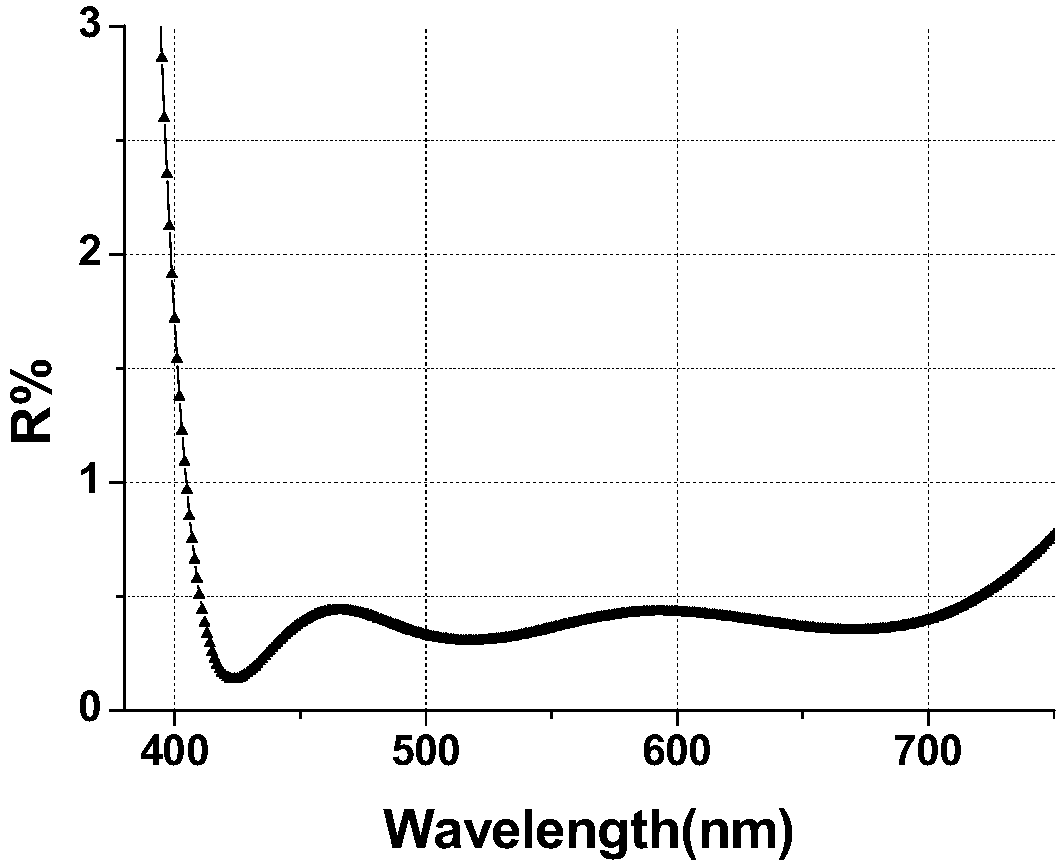

[0064] (1) Taking a conventional lens as an example, regardless of the film thickness difference between the edge and the center, pre-deposit a conventional visible light anti-reflection coating, and confirm the film thickness ratio between the center and edge of the lens. Choose TiO 2 and SiO 2 Reflectance spectra designed as coating materials such as image 3 As shown, the 420-700nm reflectance is less than 0.5%.

[0065] Each film layer is in order from near to far from the glass substrate: the first layer, TiO with a thickness of 17.1nm 2 Film layer; 2nd layer, SiO with a thickness of 24.5nm 2 Film layer; the third layer, Ti...

Embodiment 2

[0069] Choose TiO 2 , SiO 2 , MgF 2 As a coating material, the coating index confirmed according to step 3 is R figure 2 As shown, the first layer, the first SiO with a thickness of 21nm2 Film layer; the second layer, the first TiO with a thickness of 12.1 nm 2 Film layer; the third layer, SiO with a thickness of the second 53.5nm 2 Film layer; the fourth layer, the second TiO with a thickness of 8.0nm 2 Film layer; the fifth layer, the third SiO with a thickness of 217.4nm 2 Film layer; the sixth layer, the third TiO with a thickness of 13.1nm 2 Film layer; the seventh layer, the fourth SiO with a thickness of 40.6nm 2 Film layer; the 8th layer, the fourth TiO with a thickness of 36nm 2 Film layer; the ninth layer, the fifth SiO with a thickness of 11.4nm 2 ; the 10th layer, the fifth TiO with a thickness of 78.6nm 2 Film layer: the 11th layer, the sixth SiO with a thickness of 23.2nm 2 Film layer: the 12th layer, the sixth SiO with a thickness of 23.9nm 2 Film laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com