Coated glass as well as preparation method and application thereof

A glass and film coating technology, applied in the direction of coating, etc., can solve the problems that water droplets cannot achieve self-cleaning, the glass surface is easy to pollute, and reduce the visibility of imaging, so as to achieve good anti-fog effect and anti-reflection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

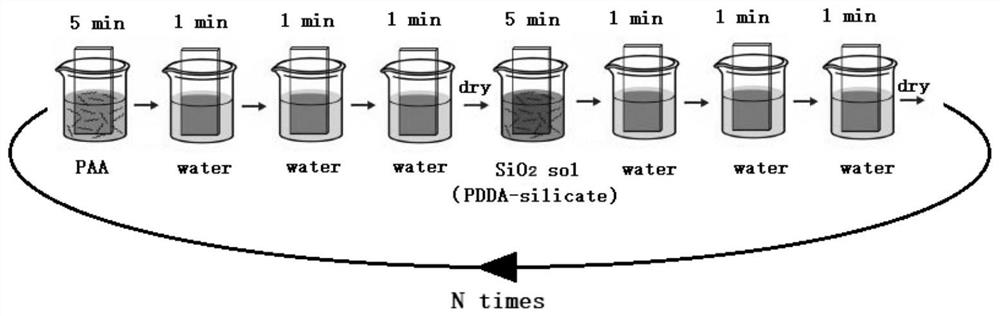

[0070] According to one aspect of the present invention, a method for preparing the above-mentioned coated glass, the preparation method includes the following steps:

[0071] (a), providing a glass substrate, then immersing the glass substrate in an ionic polymer solution, followed by cleaning and drying in sequence to obtain intermediate A;

[0072] (b), immerse intermediate A in SiO 2 Soaked in the sol, followed by cleaning and drying in turn, to obtain nanoporous SiO-coated 2 thin film glass;

[0073] (c), covered with nanoporous SiO obtained in step (b) 2 The glass of the thin film is the substrate, and the step (a) and the step (b) are repeated several times to obtain a layer of nanoporous SiO covered with several layers. 2 The thin film of glass is subsequently calcined to obtain coated glass.

[0074] The preparation method of the coated glass provided by the invention, the preparation method is to immerse the glass substrate in the ionic polymer solution and SiO ...

Embodiment 1

[0095] Embodiment 1 prepares SiO 2 sol

[0096] Provide a sodium silicate solution with a concentration of 39.10 mg / mL, and then adjust the pH of the sodium silicate solution to 4 by adding dilute sulfuric acid (1M) dropwise to obtain a sodium silicate mixed solution. Then add PDDA (2.0mg / mL) dropwise to the sodium silicate mixed solution to form SiO 2 Sol;

[0097] Wherein the volume ratio of PDDA and sodium silicate solution is 60:15.

Embodiment 2

[0099] This embodiment is the same as embodiment 1 except that the concentration of the sodium silicate solution is 19.55 mg / mL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com