Composite conductive antireflective film for crystalline silicon heterojunction solar cell

A solar cell, composite conductive technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as high temperature and affecting material transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A high-purity indium oxide ceramic target with a hafnium dioxide doping amount of 1.25wt.% was used, the substrate temperature was 200°C, and the hydrogen partial pressure was 5×10 -2 Pa.

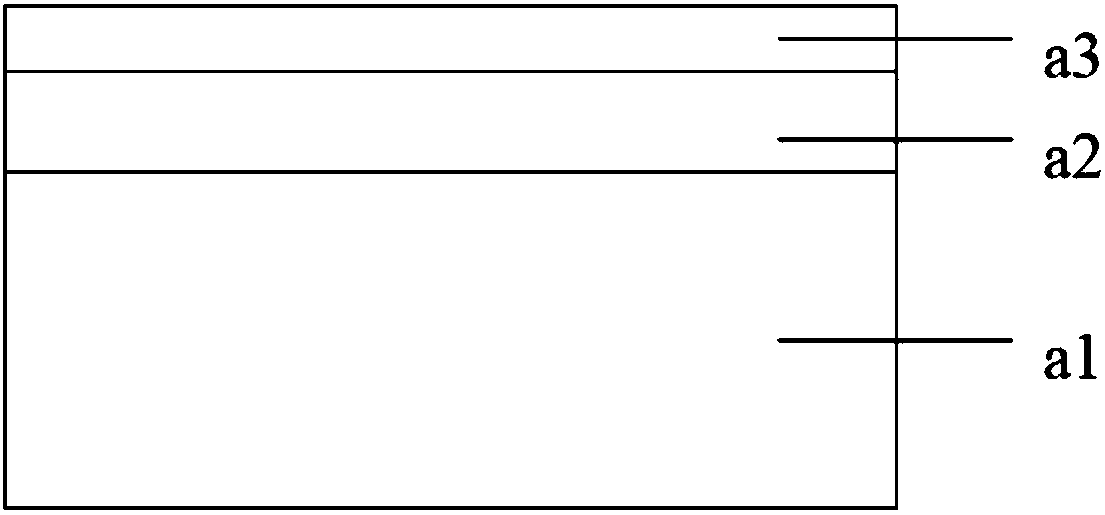

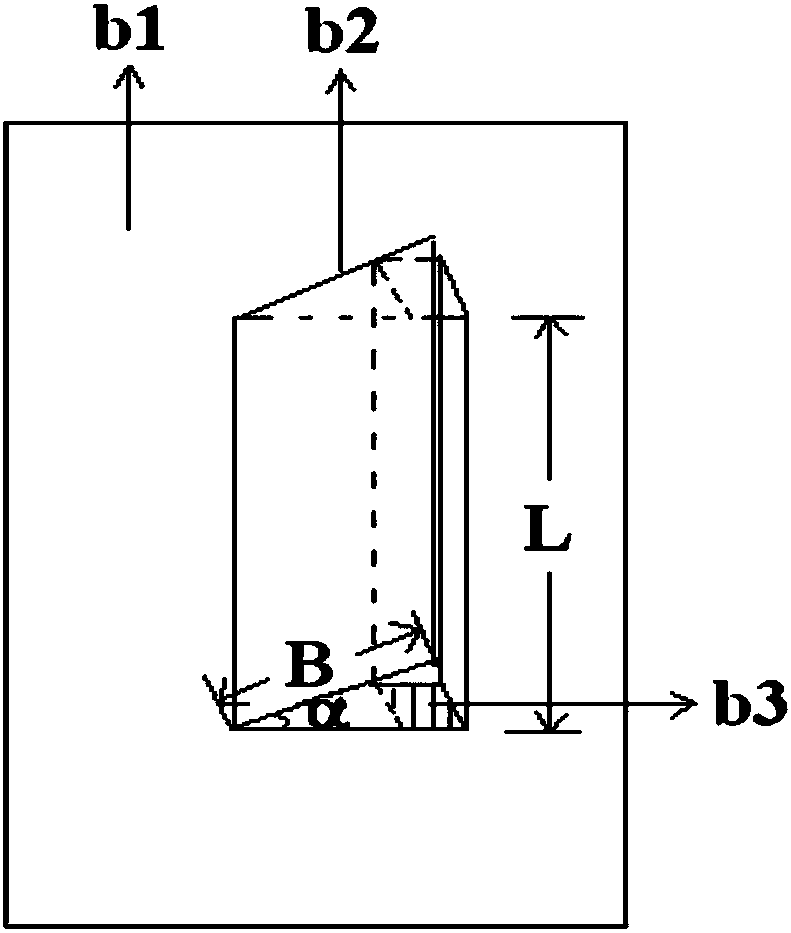

[0035] Firstly, a conventional hydrogen-hafnium co-doped indium oxide thin film a2 with a thickness of 80 nm was prepared on the doped layer on the light-facing surface of the crystalline silicon heterojunction solar cell a1 by radio frequency magnetron sputtering deposition method, and the deposition rate was The sputtering pressure is 1.2Pa. The substrate support b1 is parallel to the sputtering target surface, the substrate b2 is close to the substrate support b1, and the distance between the substrate support b1 and the target surface is 5.5 cm.

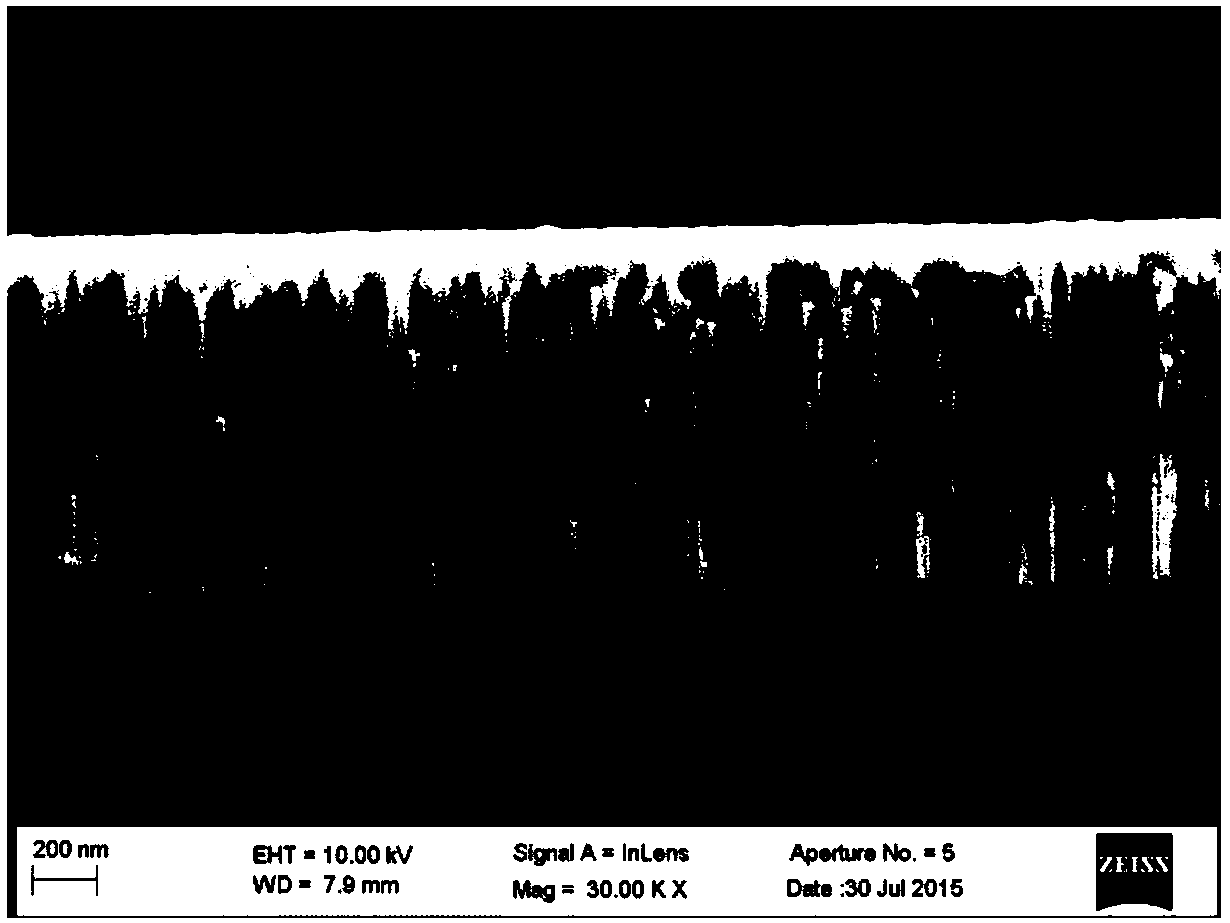

[0036] A layer of nano-column hydrogen hafnium co-doped indium oxide film a3 with a thickness of 20 nm was prepared on the conventional hydrogen-hafnium co-doped indium oxide film by radio frequency magnetron sputtering, and the deposit...

Embodiment 2

[0039] A high-purity indium oxide ceramic target with a hafnium dioxide doping amount of 0.5wt.% is used, the substrate temperature is 150°C, and the hydrogen partial pressure is 2×10 -2 Pa.

[0040] A layer of conventional hydrogen-hafnium co-doped indium oxide film a2 with a thickness of 70 nm was prepared on the surface of the doped layer on the light-facing side of the crystalline silicon heterojunction solar cell a1 by radio frequency magnetron sputtering deposition method, and the deposition rate was The sputtering pressure is 0.8Pa, the substrate support b1 is parallel to the sputtering target surface, the substrate b2 is closely attached to the substrate support b1, and the distance between the substrate support b1 and the target surface is 6cm. The refractive index of conventional hydrogen-hafnium co-doped indium oxide film prepared under this process condition is 2.1.

[0041] A layer of nano-column hydrogen hafnium co-doped indium oxide film a3 with a thickness of...

Embodiment 3

[0044] A high-purity indium oxide ceramic target with a hafnium dioxide doping amount of 2wt.% is used, the substrate temperature is 200°C, and the hydrogen partial pressure is 8×10 -2 Pa.

[0045] A conventional hydrogen-hafnium co-doped indium oxide thin film a2 with a thickness of 90 nm was first prepared on the doped layer of the crystalline silicon heterojunction solar cell a1 by radio frequency magnetron sputtering deposition method, and the deposition rate was The sputtering pressure is 1.5Pa, the substrate support b1 is parallel to the sputtering target surface, the substrate b2 is closely attached to the substrate support b1, and the distance between the substrate support b1 and the target surface is 4cm. The refractive index of conventional hydrogen-hafnium co-doped indium oxide film prepared under this process condition is 1.8.

[0046] On the conventional hydrogen-hafnium co-doped indium oxide film, a nano-column hydrogen-hafnium co-doped indium oxide film a3 wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com