A kind of chalcogenide glass substrate low residual reflectance anti-reflection film and preparation method thereof

A technology of chalcogenide glass and residual reflection, which is applied in optical components, instruments, optics, etc., can solve problems such as chalcogenide glass surface deformation, substrate deformation, and film release, so as to improve surface quality and mechanical properties, and increase firmness degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention provides a method for preparing an anti-reflection film with low residual reflectance on a chalcogenide glass substrate, comprising the following steps:

[0038] (1) Substrate cleaning: clean the surface of the chalcogenide glass to be coated with a clean degreasing gauze or cotton cloth dipped in polishing powder solution and detergent;

[0039] (2) Substrate heating: Baking and heating the coated parts before coating to increase the temperature of the substrate.

[0040] (3) Substrate pre-cleaning: Before coating, use an ion source to pre-clean the coated parts for 5-10 minutes.

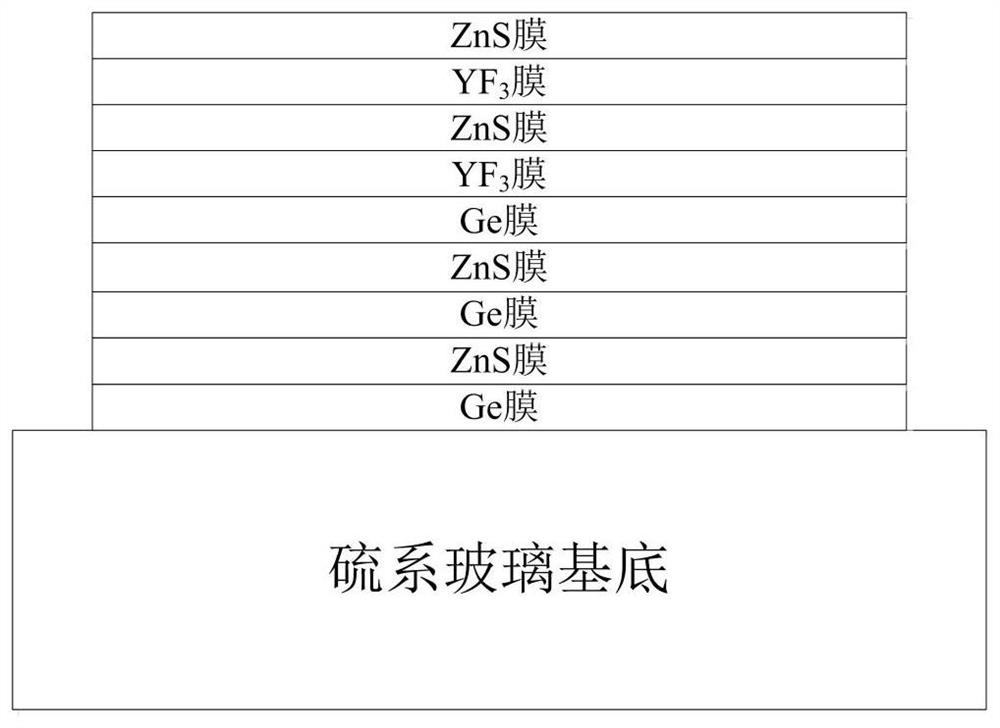

[0041] (4) Film structure design: chalcogenide glass is selected as the substrate material, Ge is the coating material with high refractive index, ZnS is the coating material with intermediate refractive index, and YF is the coating material with low refractive index 3 (or YbF 3 ), using double-sided coating to achieve low residual reflectivity anti-reflection film, the film ...

Embodiment 1

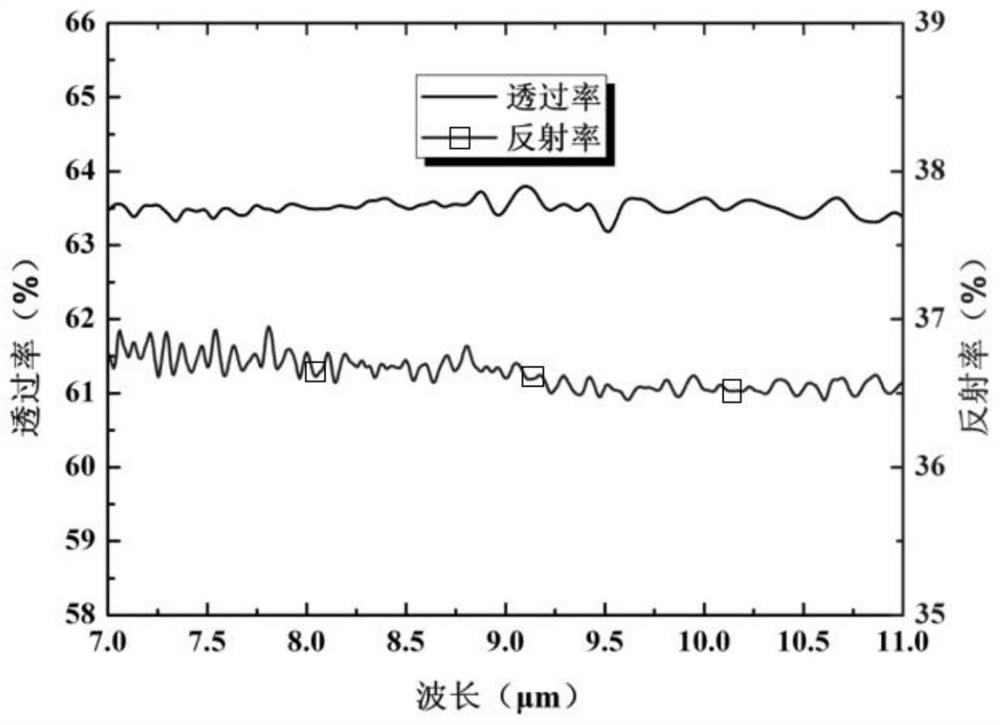

[0049] Chalcogenide glass materials (As 40 Se 60 ) as the substrate, the film structure such as figure 1 As shown, the spectral curve of the substrate before coating is as follows figure 2 shown.

[0050] (1) Use a degreasing gauze dipped in a mixture of alcohol and ether (1:1) to initially wipe the substrate. Then use a diamond polishing solution with a particle size of W0.1 to evenly wipe the surface of the lens to be coated, and finally wipe the surface of the substrate with a mixture of alcohol and ether (1:1) with absorbent gauze or cotton cloth, and check the surface of the substrate with the breath method until No oil, dust, scratches.

[0051] (2) Clean the vacuum chamber and place Ge, ZnS and YbF 3 The film material is placed in the evaporation crucible and the evaporation boat respectively.

[0052] (3) Put the cleaned substrate in the coating fixture, and then place the coating fixture on the workpiece rack in the vacuum chamber.

[0053] (4) Turn on the vac...

Embodiment 2

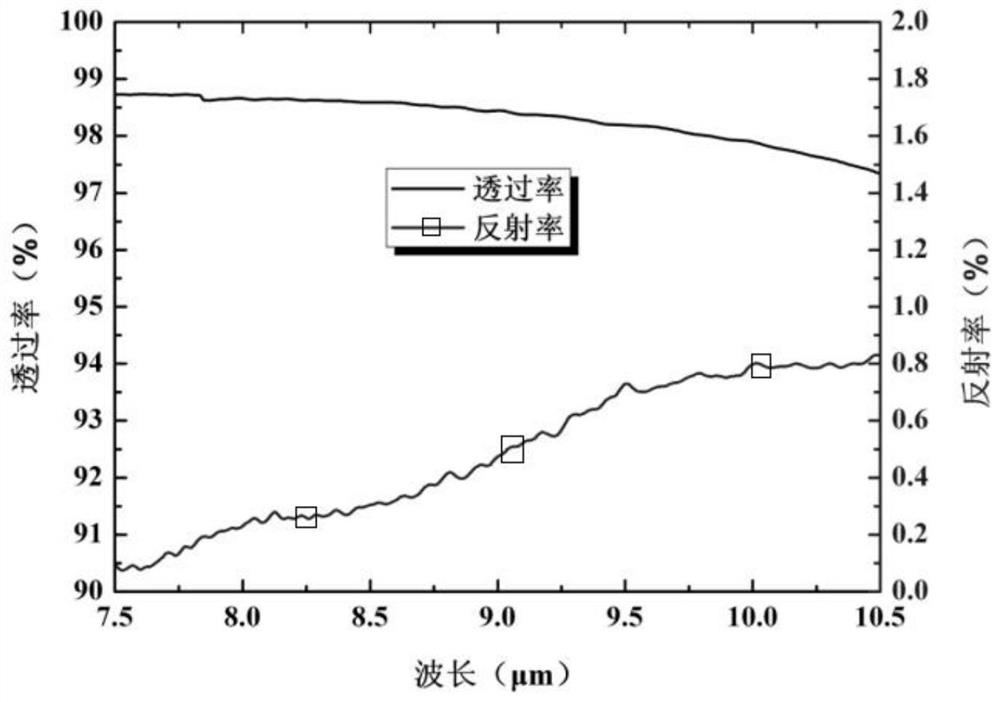

[0063] Chalcogenide glass materials (Ge 10 As 40 Se 50 ) as the substrate, the film structure such as figure 1 As shown, the spectral curve of the substrate before coating is as follows Figure 4 shown.

[0064] (1) Use a degreasing gauze dipped in a mixture of alcohol and ether (1:1) to initially wipe the substrate. Then use a diamond polishing solution with a particle size of W0.1 to evenly wipe the surface of the lens to be coated, and finally wipe the surface of the substrate with a mixture of alcohol and ether (1:1) with absorbent gauze or cotton cloth, and check the surface of the substrate with the breath method until No oil, dust, scratches.

[0065] (2) Clean the vacuum chamber and place Ge, ZnS and YbF 3 The film material is placed in the evaporation crucible and the evaporation boat respectively.

[0066] (3) Put the cleaned substrate in the coating fixture, and then place the coating fixture on the workpiece rack in the vacuum chamber.

[0067] (4) Turn on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com