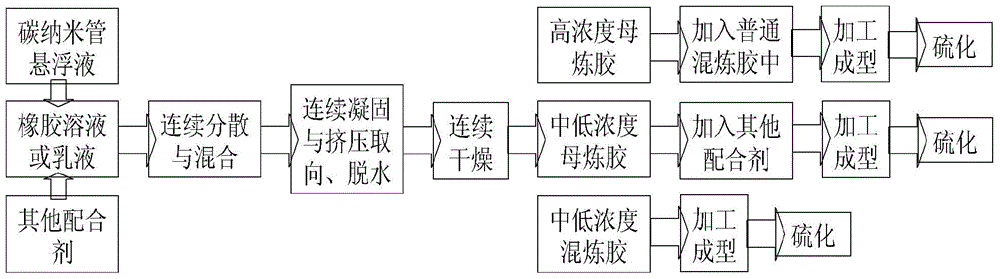

Liquid phase continuous mixing process of high dispersion carbon nanotube masterbatch and rubber product thereof

A technology of carbon nanotubes and masterbatch, which is applied in the field of liquid phase continuous mixing technology, can solve the problems of not reaching the performance of rubber products, the improvement of the performance of composite materials is not large, and the process is complicated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] (1) comparative example

[0098] Common tread rubber (commonly used in all-steel wire radial tires) used as a comparative example is prepared according to the following dry mixing method: 100 parts by weight of masticated natural rubber, 1 part by weight of accelerator N-tert-butyl-2-benzo Thiazole hypoxanthamide, 5 parts by weight of zinc oxide, 2 parts by weight of stearic acid, 1 part by weight of antioxidant N-isopropyl-N'-phenyl-p-phenylenediamine, 0.5 parts by weight of N,N'-m-phenylene Bismaleimide, 50 parts by weight of carbon black N330, 5 parts by weight of calcium carbonate, 3 parts by weight of environmentally friendly aromatic oil, 0.5 parts by weight of zinc soap salt, mixed evenly in an internal mixer, debinding at 140 ° C, and cooled Put it into an open mill to cover the rolls, add 2 parts by weight of sulfur, mix evenly, and release the sheet. After parking for 12 hours, vulcanize at 143° C. for 15 minutes to obtain a rubber product. Its product perfor...

Embodiment 1A

[0100] 1. Raw material preparation

[0101] a. Natural rubber latex

[0102] Natural Latex Components

[0103] Component

Content / parts by weight

Concentrated Latex (60%)

100

0.1

water

100

[0104] Stirring conditions: 2000-3000rpm, 2-5 minutes.

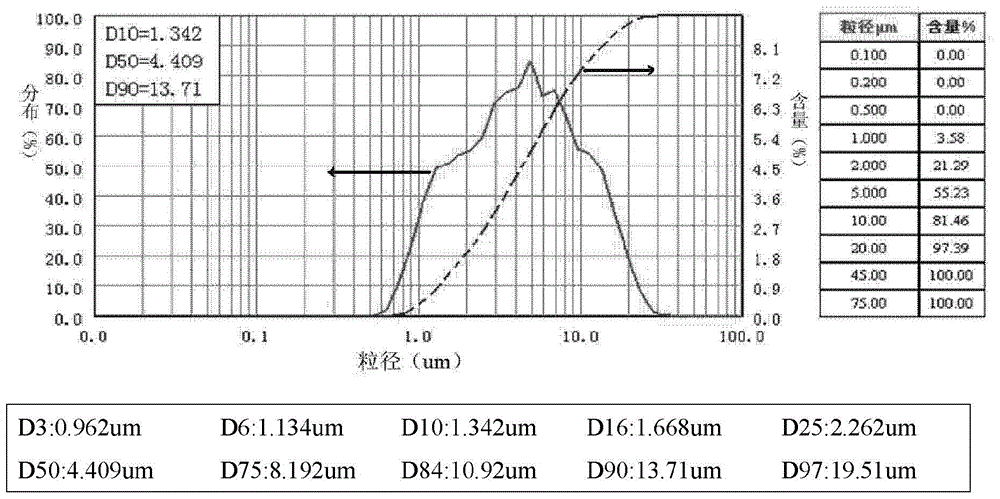

[0105] b. Carbon nanotube suspension

[0106] Carbon nanotube suspension components

[0107] Component

Content / parts by weight

carbon nanotubes

5

0.8

Stabilizer polyethylene glycol

0.8

Dispersant water

100

[0108] Stirring conditions: 2000-3000rpm, 2-5 minutes.

[0109] c. Rubber compounding agent suspension

[0110] 1 part by weight of accelerator N-tert-butyl-2-benzothiazole inosinamide, 5 parts by weight of zinc oxide, 2 parts by weight of stearic acid, 1 part by weight of anti-aging agent N-isopropyl-N'-phenyl p-Phenylenediamine, 0.5 parts by weight of N, N'-m-p...

Embodiment 1B

[0121] The rubber product of Example 1B was prepared by the dry mixing method of the ordinary tread rubber of the above comparative example, the only difference being that a masterbatch containing 1 part by weight of carbon nanotubes was added to the ordinary tread rubber formula, so The preparation method of the carbon nanotube master batch is the same as that of Example 1A, but wherein the solid content ratio of natural rubber / carbon nanotubes in the carbon nanotube master batch is 60 / 40, and the step 3) of preparing this master batch No rubber compounding agent suspension was added. Therefore, Example 1B is a rubber product prepared by using the carbon nanotube masterbatch of the present invention through ordinary dry mixing.

[0122] Table 1

[0123]

[0124]

[0125] As can be seen from the results shown in Table 1, compared with the tread rubber prepared by ordinary dry mixing, whether it is the natural rubber product or All compounding ingredients are prepared b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com