Silver/titanium dioxide composite heterostructure and preparation method thereof

A titanium dioxide and heterostructure technology, which is applied in the field of metal-semiconductor composite heterostructure material preparation, can solve problems such as rarely found, and achieve the effects of improving photocatalytic efficiency, reducing photocatalytic effect, and expanding response range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] 1.1 Disperse 0.1 mmol silver nanowires in 0.1 mL deionized water and immerse for 12 hours to obtain a suspension;

[0057] 1.2 Add 20 mL of ethanol and 100 μL of thioglycolic acid to the silver nanowire suspension described in Example 1.1, and stir well;

[0058] 1.3 Add 0.5 mL of tetrabutyl titanate to the mixture described in Example 1.2, stir and mix evenly;

[0059] 1.4 Transfer the mixed solution described in Example 1.3 to a 50 mL reactor, and react at 150 ℃ for 10 h.

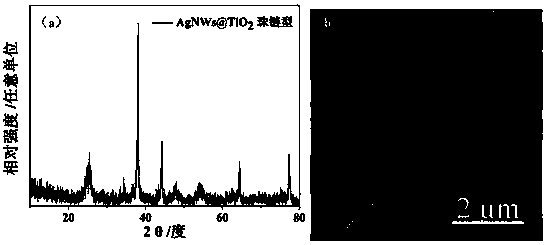

[0060] 1.5 The sample obtained in Example 1.4 was centrifuged and washed to prepare silver nanowires and TiO 2 Bead-chain heterogeneous structure (such as figure 1 As shown), the average diameter of titanium dioxide spheres is 600 nm, and the diameter of silver nanowires is 40 nm.

Embodiment 2

[0062] 2.1 Disperse 0.1 mmol silver nanowires in 0.1 mL deionized water and soak for 4 hours to obtain a suspension;

[0063] 2.2 Add 20 mL methanol and 20 μL thioglycolic acid to the silver nanowire suspension described in Example 2.1, and stir well;

[0064] 2.3 Add 0.5 mL of tetrapropyl titanate to the mixture described in Example 2.2, stir and mix evenly;

[0065] 2.4 Transfer the mixed solution described in Example 2.3 to a 50 mL reactor, and react at 150°C for 10 h.

[0066] 2.5 The sample obtained in Example 2.4 was centrifuged and washed to prepare silver nanowires and TiO 2 Bead-chain heterostructure, the average diameter of titanium dioxide spheres is 560 nm, and the diameter of silver nanowires is 10 nm.

Embodiment 3

[0068] 3.1 Disperse 0.1 mmol silver nanowires in 0.1 mL deionized water and immerse for 8 hours to obtain a suspension;

[0069] 3.2 Add 20 mL of propanol and 50 μL of thioglycolic acid to the silver nanowire suspension described in Example 3.1, and stir evenly;

[0070] 3.3 Add 0.025 mL of isopropyl titanate to the mixture described in Example 3.2, stir and mix evenly;

[0071] 3.4 Transfer the mixed solution described in Example 3.3 to a 50 mL reactor, and react at 150°C for 10 hours.

[0072] 3.5 The sample obtained in Example 3.4 was centrifuged and washed to prepare silver nanowires and TiO 2 Bead-chain heterostructure, the average diameter of titanium dioxide spheres is 200 nm, and the diameter of silver nanowires is 60 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com