Flattening adjuster for film covering machine

A regulator and laminating machine technology, applied in the field of regulators, can solve problems such as air bubbles and wrinkles in the laminating machine, and achieve the effects of easy film application, easy operation, and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

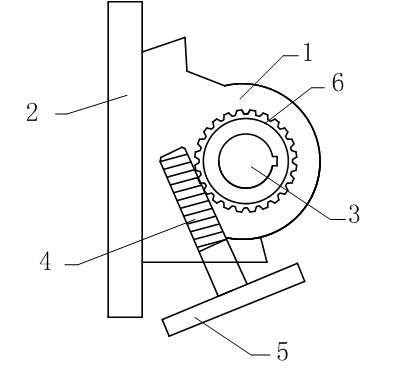

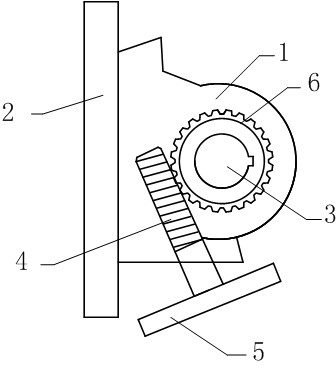

[0013] Such as figure 1 The shown flattening regulator for the laminating machine includes a spherical shaft housing 1. In order to facilitate connection with the laminating machine, connecting brackets 2 are provided at both ends of the spherical shaft housing 1. The special feature of the present invention is: The adopted spherical shaft housing 1 is provided with a spherical toothed shaft sleeve 3 . At the same time, considering that the curved surface of the entire flattening adjuster can be effectively adjusted, an adjusting device is connected to the adjusting end of the spherical gear sleeve 3 .

[0014] As far as a preferred embodiment of the present invention is concerned, the adjusting device used in the present invention is the adjusting screw 4 in consideration of better adjustment. Specifically, the helical end of the adjusting screw 4 is in contact with the adjusting end of the spherical gear sleeve 3 . At the same time, an adjustment handle 5 is distributed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com