Method for preparing solid polymer electrolyte lithium ion battery

A solid-state polymer, lithium-ion battery technology, used in the preparation of gel/all-solid-state polymer electrolyte lithium-ion batteries, based on in-situ electrospinning to prepare solid-state polymer electrolyte lithium-ion batteries, can solve the precursor solution phase Poor tolerance, increased ohmic polarization of the battery, and low porosity of the separator, to achieve the effects of high mechanical strength, stable capacity, and stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

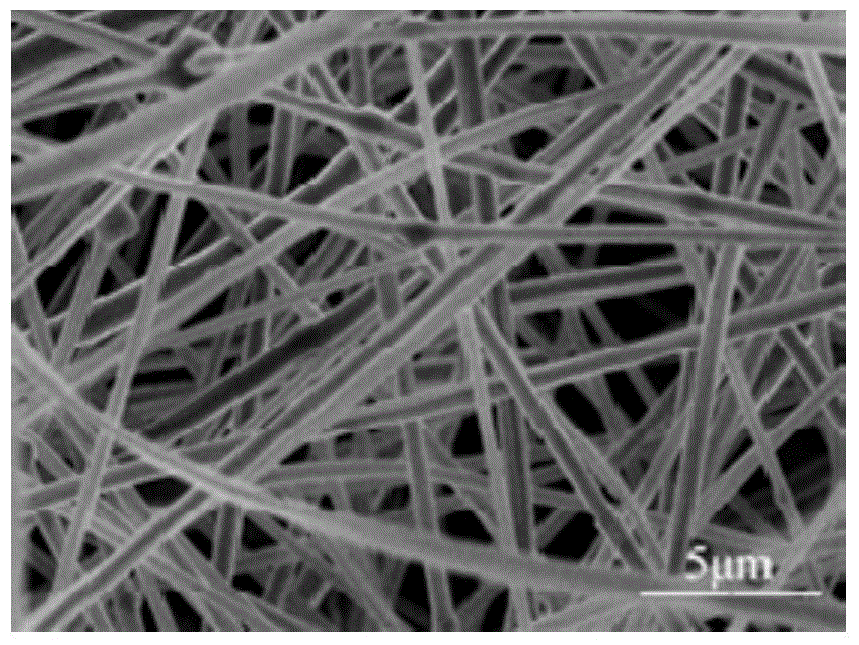

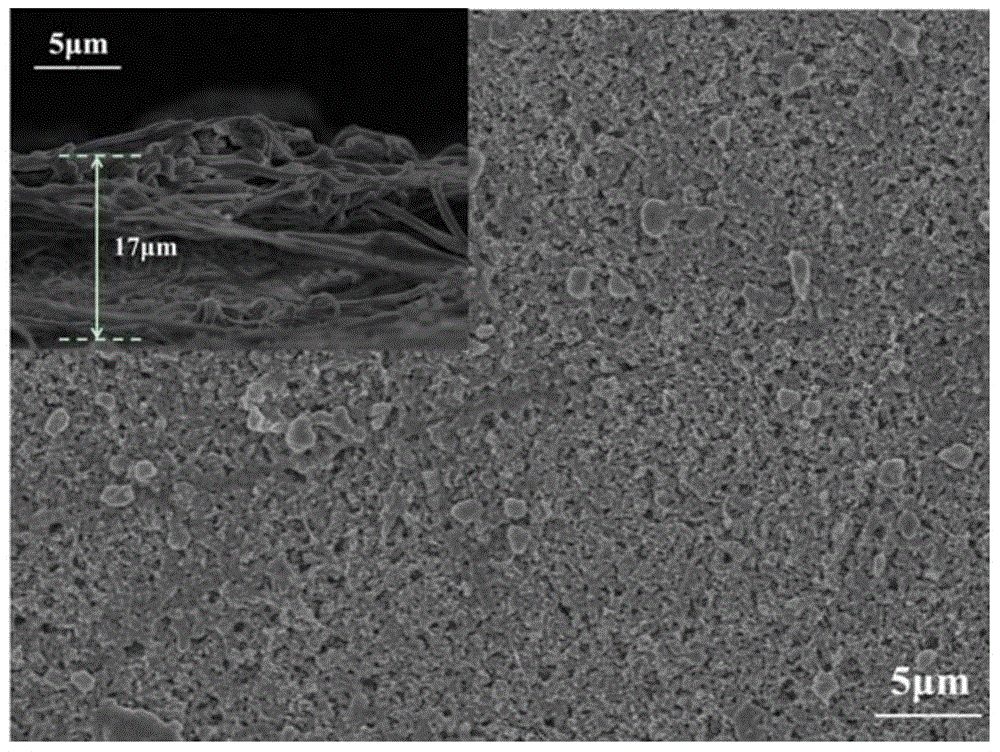

[0029] Step 1) Dissolve polymethyl methacrylate in tetrahydrofuran to obtain a solution for electrospinning with a mass fraction of 25%, and then add the solution for electrospinning into the syringe of the electrospinning device, and the moving speed of the nozzle is 50mm / s, the moving distance is 300mm, the spinning temperature is 50°C, and the electrospinning is performed under the conditions of the voltage 20kV, and a 20-micron-thick electrospinning fiber membrane is obtained on the receiver covered with the lithium cobalt oxide electrode membrane;

[0030] Step 2) Weigh the following components according to the following mass relationship, succinonitrile: acrylonitrile: lithium hexafluorophosphate: boron trifluoride=75:10:14.9:0.1. heating and melting succinonitrile at 60°C, adding acrylonitrile, lithium hexafluorophosphate and boron trifluoride into the succinonitrile melt and mixing them uniformly to obtain a solid polymer electrolyte precursor;

[0031] Step 3) heatin...

Embodiment 2

[0034] Step 1) Dissolving polyacrylonitrile in acetone to obtain a solution for electrospinning with a mass fraction of 30%, then adding the solution for electrospinning into the syringe of the electrospinning device, moving the nozzle at a speed of 50mm / s, moving Electrospinning was carried out at a distance of 300mm, a spinning temperature of 50°C, and a voltage of 20kV, and an electrospun fiber membrane with a thickness of 20 microns was obtained on a receiver covered with a graphite electrode membrane;

[0035] Step 2) Take the following components according to the following mass relationship, isophthalonitrile: diethylene glycol dimethacrylate: lithium bis(trifluoromethylsulfonate) imide: azobisisobutyronitrile=70 :15:14.5:0.5. Heat and melt isophthalonitrile at 50°C, add diethylene glycol dimethacrylate, lithium bis(trifluoromethylsulfonate)imide, and azobisisobutyronitrile into isophthalonitrile melt After mixing uniformly, the solid polymer electrolyte precursor is ob...

Embodiment 3

[0039] Step 1) dissolving polyvinylidene fluoride in acetonitrile to obtain a solution for electrospinning with a mass fraction of 20%, then adding the solution for electrospinning into the syringe of the electrospinning device, and moving the nozzle at a speed of 50mm / s, Electrospinning was carried out under the conditions of a moving distance of 300mm, a spinning temperature of 50°C, and a voltage of 20kV, and an electrospun fiber membrane with a thickness of 20 microns was obtained on the receiver covered with a lithium cobalt oxide electrode membrane;

[0040] Step 2) Take the following components according to the following mass relationship, ethylene carbonate: diethyl carbonate: ethyl methyl carbonate: triethylene glycol diacrylate: lithium hexafluorophosphate: lauroyl peroxide=20:30:30:10: 9.8:0.2. Adding triethylene glycol diacrylate, lithium hexafluorophosphate, and lauroyl peroxide into a solvent of ethylene carbonate and diethyl carbonate and mixing them uniformly t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com