PVC (polyvinyl chloride)/metal bonding hot melt adhesive film and preparation method thereof

A hot-melt adhesive film and metal bonding technology, which is applied in the direction of film/sheet adhesives, adhesives, adhesive types, etc., can solve the problems of large solvent pollution, solvent pollution, and long time consumption, so as to improve the adhesion The effect of strong junction strength, less environmental pollution, and good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

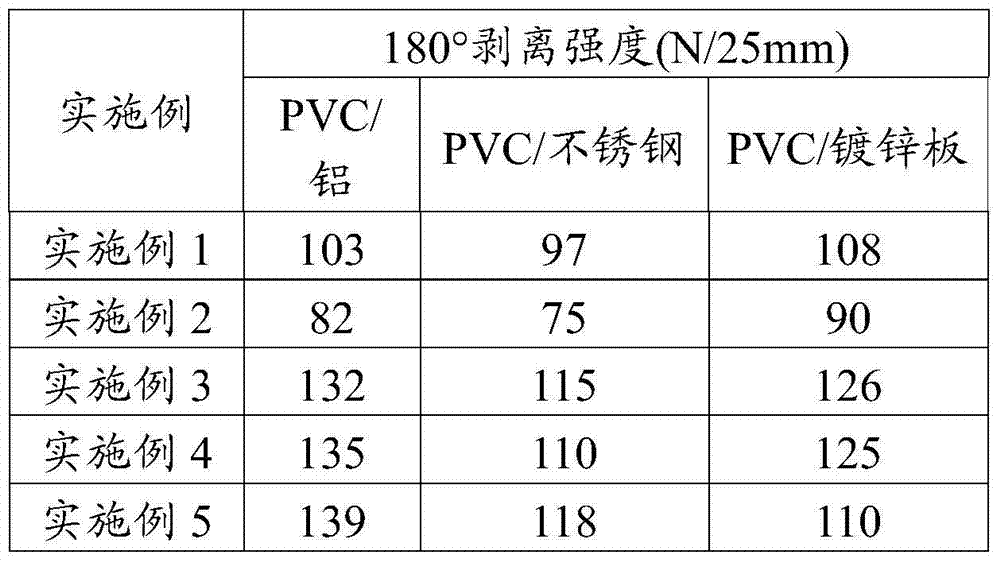

[0034] 20 parts by weight of maleic anhydride grafted polyethylene-vinyl acetate copolymer (Guangzhou Lushan New Material Co., Ltd., OV-1), 70 parts of polyethylene-vinyl acetate copolymer (DuPont, Elvax250), 10 parts of polyolefin elastomer (Dow Chemical, ENGAGE8200), 0.5 parts of 1,1-di-tert-butylperoxy-3,3,5-trimethylcyclohexane, 1.2 parts of vinyl Trimethoxysilane and 1 part of trimethylolpropane triacrylate are mixed with a high-speed mixer, sealed and placed for 24 hours, so that the initiator, silane, and crosslinking agent are fully absorbed by the polymer matrix. ℃ extrusion granulation, and then cast the rubber granules at 85 ℃ with a casting machine to obtain a hot melt adhesive film with a thickness of 0.15 mm. Investigate the 180° peel strength of the adhesive film bonded to PVC / aluminum, PVC / stainless steel, PVC / galvanized sheet at 150°C, 0.3MPa, and hot pressing for 30s. The specific test results are shown in Table 1.

Embodiment 2

[0036] 15 parts by weight of maleic anhydride modified polyethylene-ethyl acrylate copolymer (Arkema, Lotader8200), 60 parts of polyethylene-butyl acrylate copolymer (Arkema, LORTYL35BA40), 25 parts EPDM copolymer (Dow Chemical, NORDEL IP3720P), 0.7 part of tert-amyl peroxide 2-ethylhexyl carbonate, 0.5 part of vinyltriethoxysilane, 0.1 part of dipentaerythritol hexaacrylate The esters are mixed with a high-speed mixer, sealed and stored for 4 hours, so that the initiator, silane, and crosslinking agent are fully absorbed by the polymer matrix, extruded at 120°C with an extruder to granulate, and then the rubber granules are cast on a casting machine. Cast at 125°C to obtain a hot melt adhesive film with a thickness of 0.15 mm. Investigate the 180° peel strength of the adhesive film bonded to PVC / aluminum, PVC / stainless steel, PVC / galvanized sheet at 150°C, 0.3MPa, and hot pressing for 30s. The specific test results are shown in Table 1.

Embodiment 3

[0038]30 parts by weight of maleic anhydride modified polyethylene-ethyl acrylate copolymer (Arkema, Lotader4210), 40 parts of polyethylene-butyl acrylate copolymer (DuPont, Elvaloy AC34035), 30 parts Amorphous α-olefin copolymer (Degussa, APAO792), 0.1 part of 1,1-di-tert-butylperoxycyclohexane, 0.2 part of vinyltrimethoxysilane, 0.3 part of triallyl The base isocyanurate is mixed with a high-speed mixer, sealed and stored for 12 hours, so that the initiator, silane, and cross-linking agent are fully absorbed by the polymer matrix, and extruded at 100°C with an extruder to granulate, and then the rubber particles Cast at 105°C with a casting machine to obtain a 0.15 mm thick hot melt adhesive film. Investigate the 180° peel strength of the adhesive film bonded to PVC / aluminum, PVC / stainless steel, PVC / galvanized sheet at 150°C, 0.3MPa, and hot pressing for 30s. The specific test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com