Nanocellulose enhanced full-biodegradable thin film and preparation method thereof

A nanocellulose and degradable film technology, applied in flat products, other household appliances, applications, etc., can solve the problems of poor air permeability, insignificant enhancement effect, and low material strength of biodegradable films, and achieve smooth appearance and simple method. Easy to operate, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

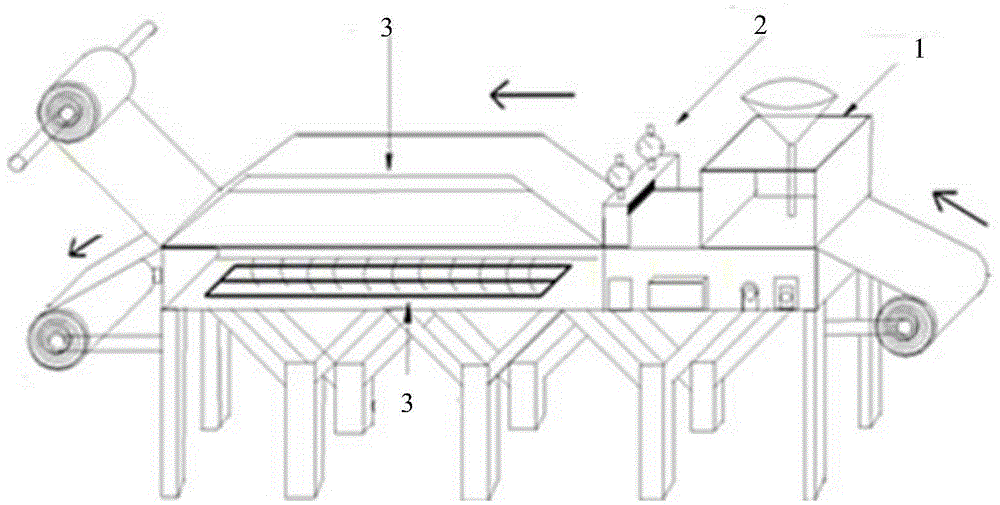

Image

Examples

Embodiment 1

[0058] The fully biodegradable film reinforced by nanocellulose is carried out by casting method, and the specific steps are as follows:

[0059] (1) Pour 30g of deionized water into a 100mL beaker and heat it to 60°C. Slowly add 6 parts by weight of nanocrystalline cellulose (NCC), 24 parts by weight of gelatin and 0.4 part of ethanol defoamer in parts by weight, until forming nanocellulose aqueous phase colloid;

[0060] (2) Add 0.5 part by weight of xanthan gum gel and 0.01 part by weight of potassium chloride coagulant in the nanocellulose aqueous phase colloid obtained in step (1), fully mix and obtain Gel mixture containing nanocellulose;

[0061] (3) add by weight 0.4 part of glycerol plasticizer, 0.7 part of xylitol dispersant and 0.4 part of genipin crosslinking agent in the gel mixed solution containing nanocellulose that step (2) obtains, fully Mix to obtain a uniform pre-crosslinking mixture;

[0062] (4) After weighing the uniform pre-crosslinked mixed solution...

Embodiment 2

[0078] The fully biodegradable film reinforced by nanocellulose is carried out by casting method, and the specific steps are as follows:

[0079] (1) Pour 30g of deionized water into a 100mL beaker and heat it to 60°C. Slowly add 15 parts by weight of nanocrystalline cellulose (NCC), 50 parts by weight of gelatin and 1.5 parts of ethanol defoamer in parts by weight, until forming nanocellulose aqueous phase colloid;

[0080] (2) Add 1.5 parts by weight of xanthan gum gel and 0.15 parts by weight of potassium chloride coagulant in the nanocellulose aqueous phase colloid obtained in step (1), fully mix to obtain Gel mixture containing nanocellulose;

[0081] (3) add by weight 1.5 parts of glycerol plasticizers, 3.5 parts of xylitol dispersants and 1.2 parts of genipin crosslinking agents in the gel mixed solution containing nanocellulose obtained in step (2), fully Mix to obtain a uniform pre-crosslinking mixture;

[0082] (4) After weighing the uniform pre-crosslinked mixed ...

Embodiment 3

[0088] The fully biodegradable film reinforced by nanocellulose is carried out by casting method, and the specific steps are as follows:

[0089] (1) Pour 30g of deionized water into a 100mL beaker, and heat it to 60°C, slowly add 50 parts by weight of nanocrystalline cellulose (NCC), 100 parts by weight of gelatin and 9.37 parts of ethanol defoamer in parts by weight, until forming nanocellulose aqueous phase colloid;

[0090] (2) Add 12.5 parts by weight of xanthan gum gel and 0.15 parts by weight of potassium chloride coagulant in the nano-cellulose aqueous phase colloid obtained in step (1), fully mix and obtain Gel mixture containing nanocellulose;

[0091] (3) add by weight 10.5 parts of glycerol plasticizers, 5.5 parts of xylitol dispersants and 1.2 parts of genipin crosslinking agents in the gel mixed solution containing nanocellulose that step (2) obtains, fully Mix to obtain a uniform pre-crosslinking mixture;

[0092] (4) After weighing the uniform pre-crosslinki...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com