Preparation method of micron-sized garnet type inorganic solid electrolyte membrane

A garnet-type, inorganic solid technology, applied in the manufacture of electrolyte batteries, electrolytes, non-aqueous electrolyte batteries, etc., can solve problems such as unfavorable battery energy density and power density, limit industrial application prospects, and complex equipment, and achieve low cost, Easy-to-control, simple-to-equip effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

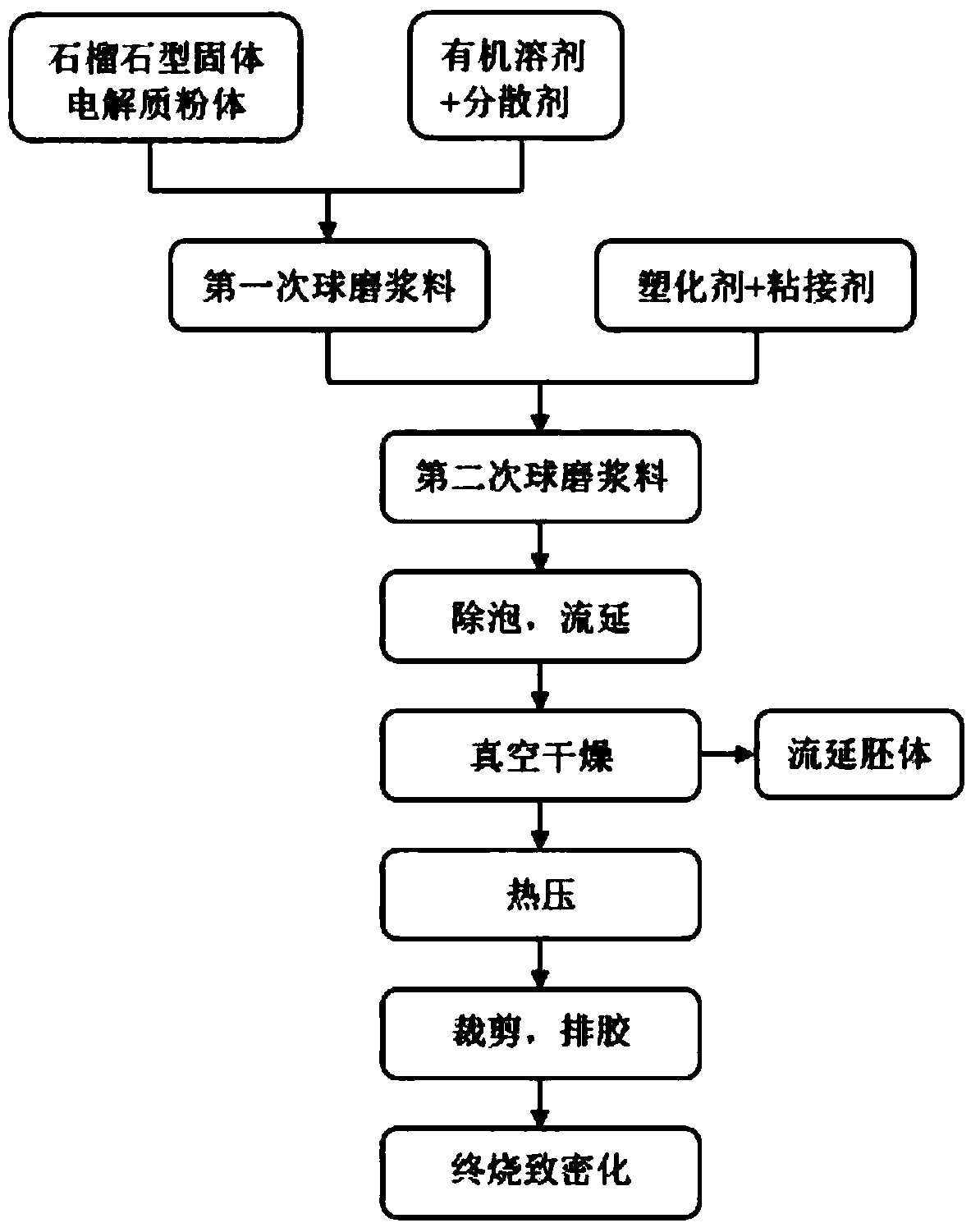

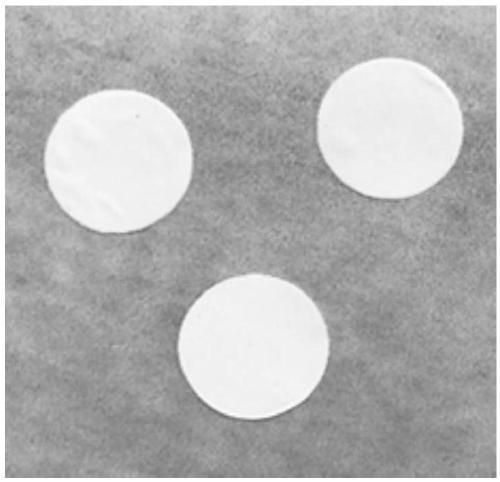

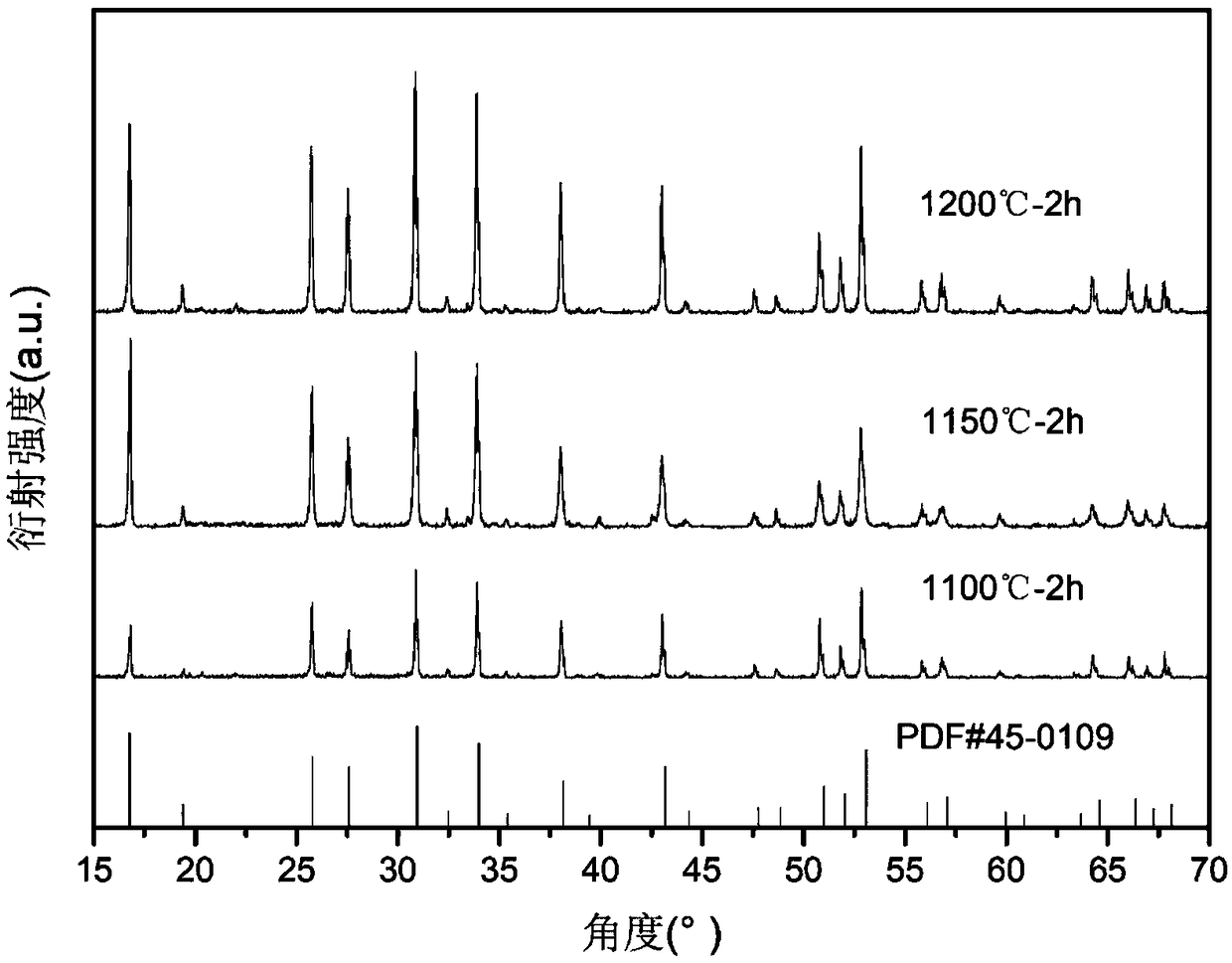

[0029] refer to figure 1 In the process flow shown, the garnet-type solid electrolyte Li prepared by the sol-gel method is first 6.25 Al 0.25 La 3 Zr 2 o 12 The powder was put into an agate mortar, manually ground for 30 minutes, and passed through a 500-mesh sieve. Weigh 6g of the sieved powder and add it into a zirconia ball mill jar, the mass ratio of zirconia balls to powder is 4:1. Then add 2.7 g of ethanol, 2.7 g of butanone and 0.15 g of castor oil, and ball mill at a speed of 300 r / min for 12 h. After the first ball milling, add plasticizer dibutyl phthalate (DBP) and binder polyvinyl butyral (PVB) 0.42g each, and continue ball milling at 300r / min for 24h to obtain stable And evenly dispersed cast slurry. The casting slurry was used as raw material to cast on a casting machine, and the height of the scraper was controlled to be 500 μm. The obtained wet film was vacuum-dried at 45° C. for 24 hours to obtain a casting green body with good processability. The cast...

Embodiment 2

[0031] The garnet-type solid electrolyte Li prepared by the traditional solid-state method 5 La 3 Nb 2 o 12The powder was put into an agate mortar, manually ground for 60 minutes, and passed through a 300-mesh sieve. Weigh 6g of the sieved powder and add it into a zirconia ball mill jar, the mass ratio of zirconia balls to powder is 3:1. Then add 3.2g each of ethanol and toluene and 0.18g of KD-1 dispersant, and ball mill at 400r / min for 18h. After the first ball milling, add plasticizer butyl benzyl phthalate (BBP) and binder PVB 0.45g each, and continue ball milling at 400r / min for 18 hours to obtain a stable and uniformly dispersed casting slurry material. The casting slurry was used as the raw material for casting on a casting machine, and the height of the scraper was controlled to be 300 μm. The obtained wet film was vacuum-dried at 60° C. for 36 hours to obtain a casting green body with good processability. The cast body was hot-pressed at 80°C for 0.5h, cut into ...

Embodiment 3

[0033] The garnet-type solid electrolyte Li prepared by plasma activation sintering 6.4 La 3 Zr 1.4 Ta 0.6 o 12 The powder was put into an agate mortar, manually ground for 45 minutes, and passed through a 300-mesh sieve. Weigh 6g of the sieved powder and add it into a zirconia ball mill jar, the mass ratio of zirconia balls to powder is 2.5:1. Then add 9.0 g of trichlorethylene and 0.12 g of fish oil, and ball mill at a speed of 200 r / min for 24 hours. After the first ball milling, 0.45 g of plasticizer ethylene glycol and 0.36 g of adhesive polymethylacrylate were added, and ball milling was continued for 24 hours at a speed of 300 r / min to obtain a stable and uniformly dispersed casting slurry. The casting slurry was used as raw material to cast on a casting machine, and the height of the scraper was controlled to be 400 μm. The obtained wet film was vacuum-dried at 80° C. for 24 hours to obtain a cast green body with good processability. The cast body was hot-pressed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com