Deposition friction stir welding process and apparatus

A technology of friction stir welding and friction heating, which is applied in welding equipment, welding/welding/cutting items, non-electric welding equipment, etc., and can solve problems such as potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

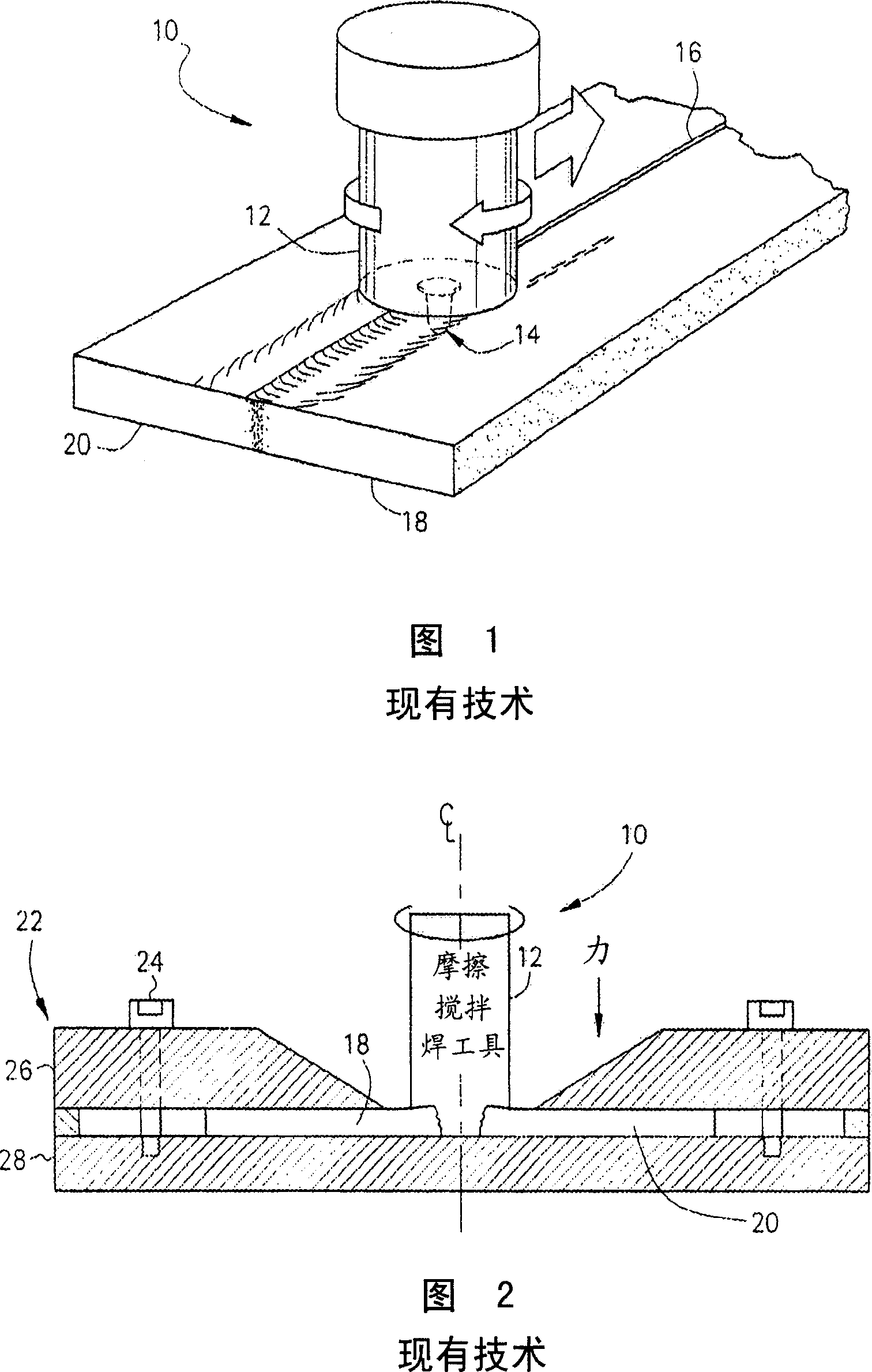

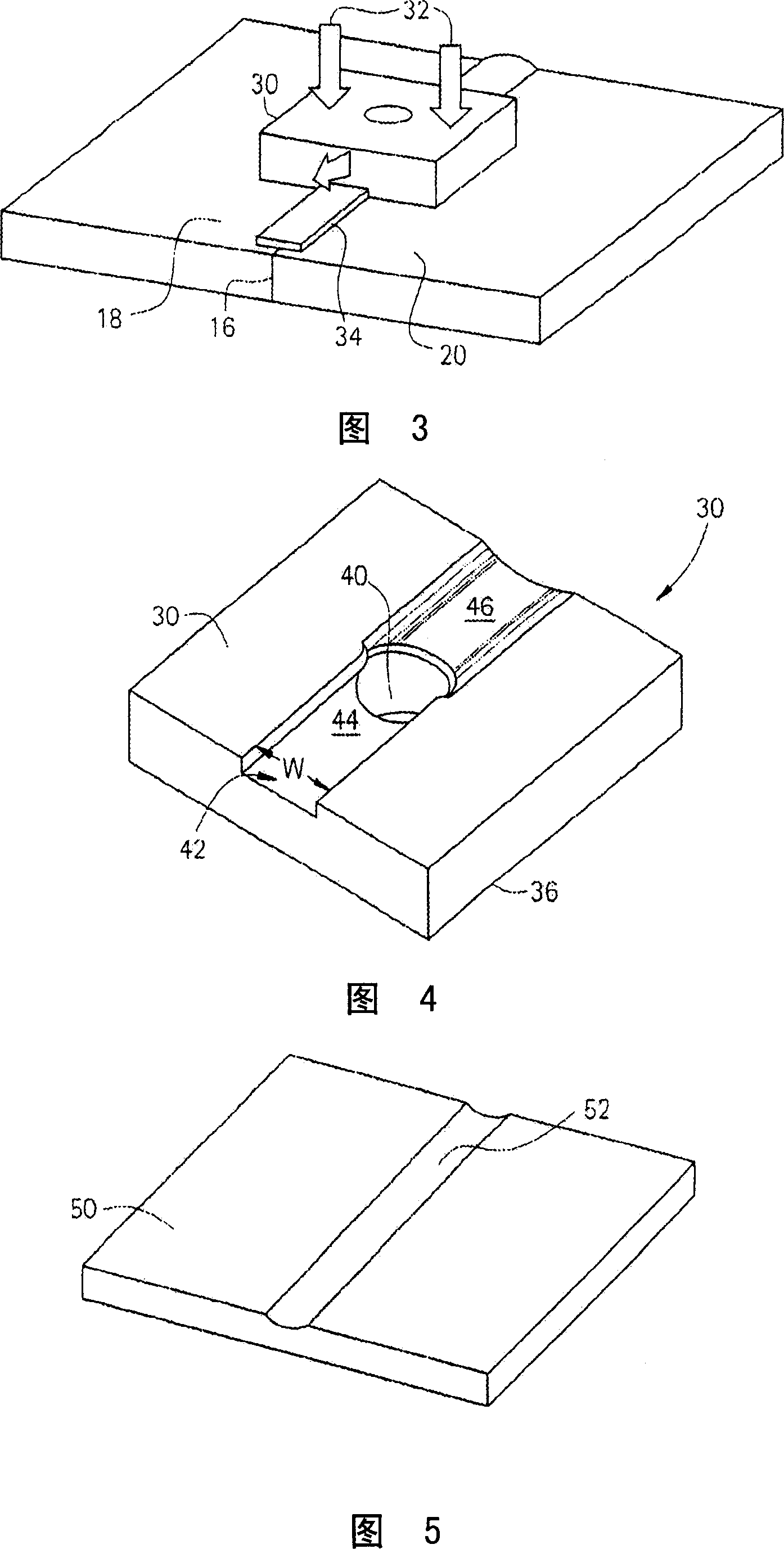

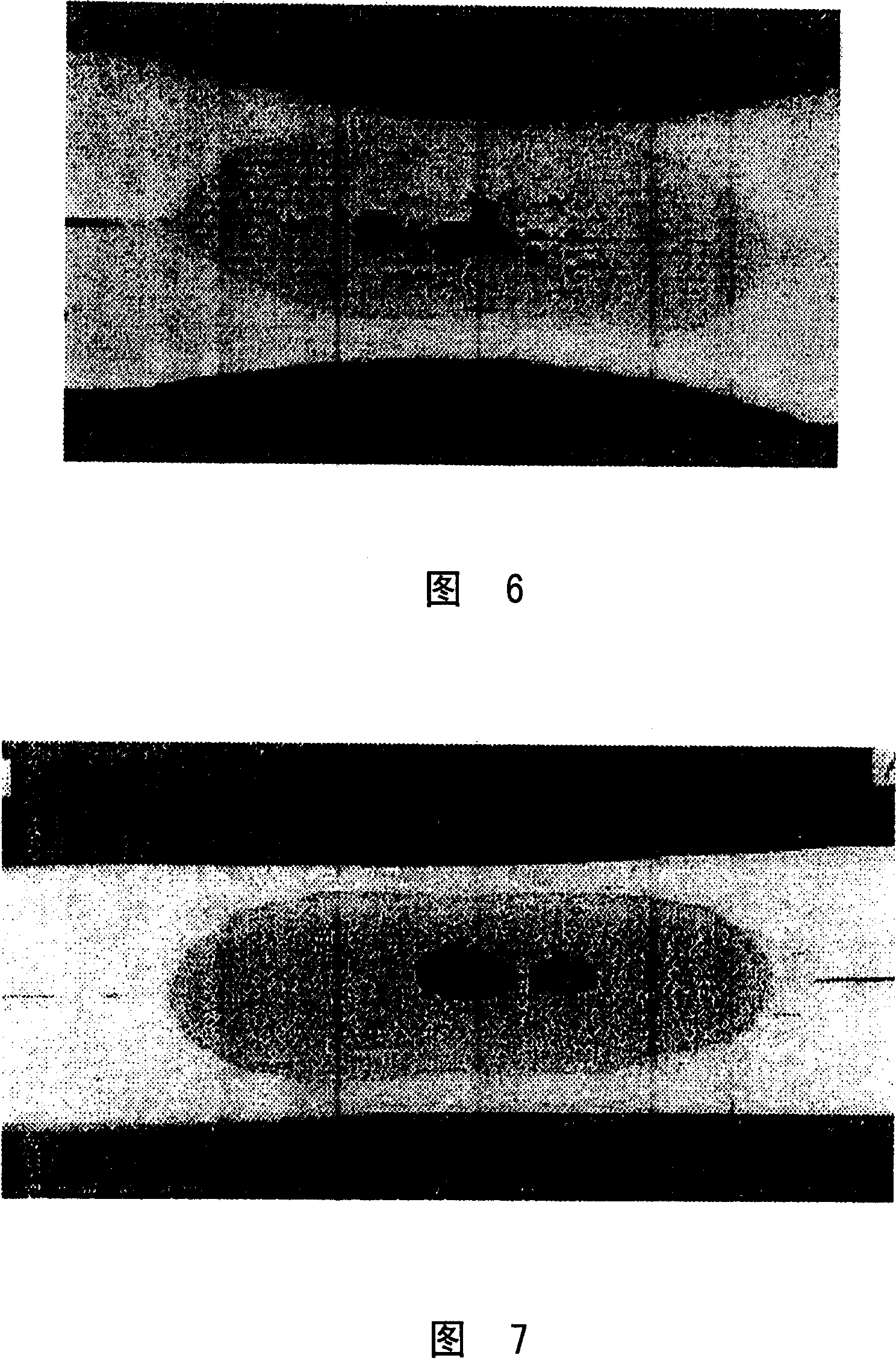

[0021] Applicants have disclosed a friction stir welding method that can compensate for the problems of weld sparks and general thinning of material along the joint during the solid state joining operation of two or more workpieces. According to the friction stir welding method disclosed in the present invention, it utilizes the so-called process of depositing additional solid material (herein also referred to as filler material) along the joint area of the joint joint during friction stir welding of two or more butt-joint workpieces. depositional friction stir welding method. As described in detail below, additional solid material is introduced into the joint region in such a way as to pin down the weld free surface and shape the weld profile. Likewise, final welds can be formed with thicker cross-sectional thicknesses than prior art friction stir welding methods, thereby overcoming many of the above-mentioned prior art problems and providing a variety of Application, more...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com