Intelligent hierarchical control method and control device for ore grinding in concentration plant

A hierarchical control and concentrator technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of large errors and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

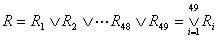

[0063] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0064] Such as figure 1 As shown, the grinding process is generally divided into two stages of grinding and classification. The first stage of grinding generally adopts self-grinding or semi-self-grinding method, and the larger ore brought by the mining plant is initially ground, and the ground iron ore slurry is classified by a cyclone, and its overflow flows to the next The bottom flow is returned to the first stage of self-grinding machine for re-grinding. The second-stage grinding adopts the ball milling method. The iron ore that has been ground in the first-stage self-grinding machine is continued to be ground, and then classified again through the second-stage cyclone. The overflow flows to the beneficiation process, and the bottom flow returns to the second Segment ball mill for regrinding.

[0065] Such as figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com