Device and method for drilling and forming hole in coal rock in structural belt

A technology of hole-forming device and structural belt, which is applied in the direction of drilling equipment and methods, safety devices, drill bits, etc., to achieve the effects of increasing hole-forming rate, improving safety, and life safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

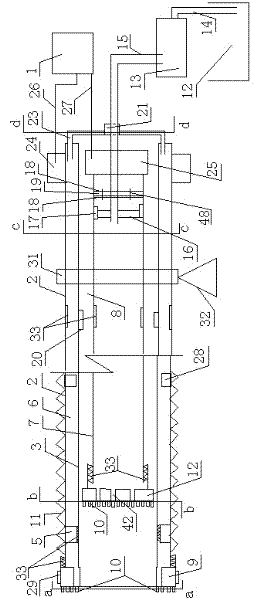

[0041] The direction in this embodiment takes the drilling direction as the forward direction, that is, the outer drill bit is located at the front end of the coal and rock drilling device in the structural belt. figure 1 Middle mark 33 is the threaded joint between each part.

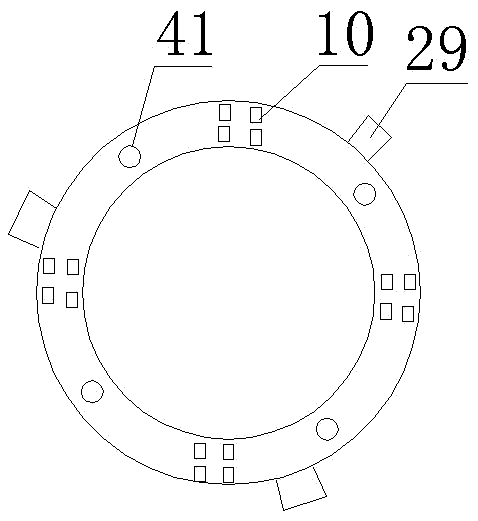

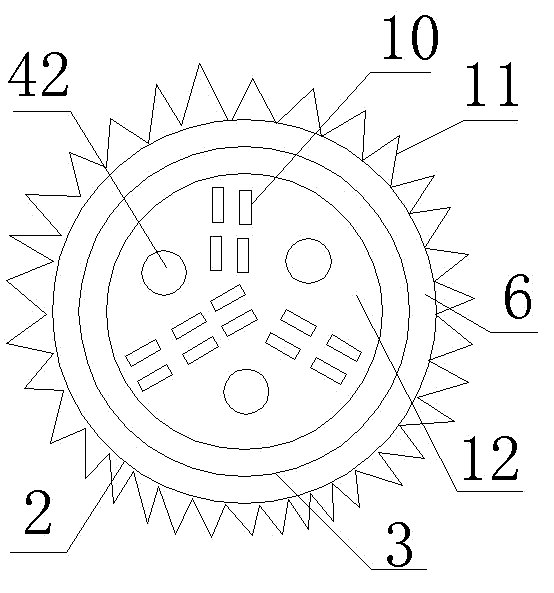

[0042] Such as Figure 1 to Figure 7 As shown, the coal rock drilling device in the structural zone of the present invention includes a power unit 1, a drill rod mechanism and a water injection mechanism.

[0043] Such as Figure 1 to Figure 7 As shown, the drill rod mechanism includes an outer drill rod, and the outer drill rod includes an outer wall 2 and an inner wall 3 that are sleeved together concentrically. The outer wall 2 includes more than two cylindrical outer wall sections that are connected together by screwing, Such as Figure 7 As shown, the outer wall 2 is cut with cracks 4 parallel to the axial direction of the drill pipe (of course, due to the needs of gas extraction, only the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com