Three-dimensional (3D) horizontal well drilling construction method

A construction method and technology for horizontal wells, which are applied in drilling equipment and methods, drilling equipment, directional drilling, etc., can solve the problems of increasing difficulty in construction, great difficulty in construction, and short construction time, and avoid time and construction. The amount of engineering, drilling and orientation are convenient, and the effect of saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

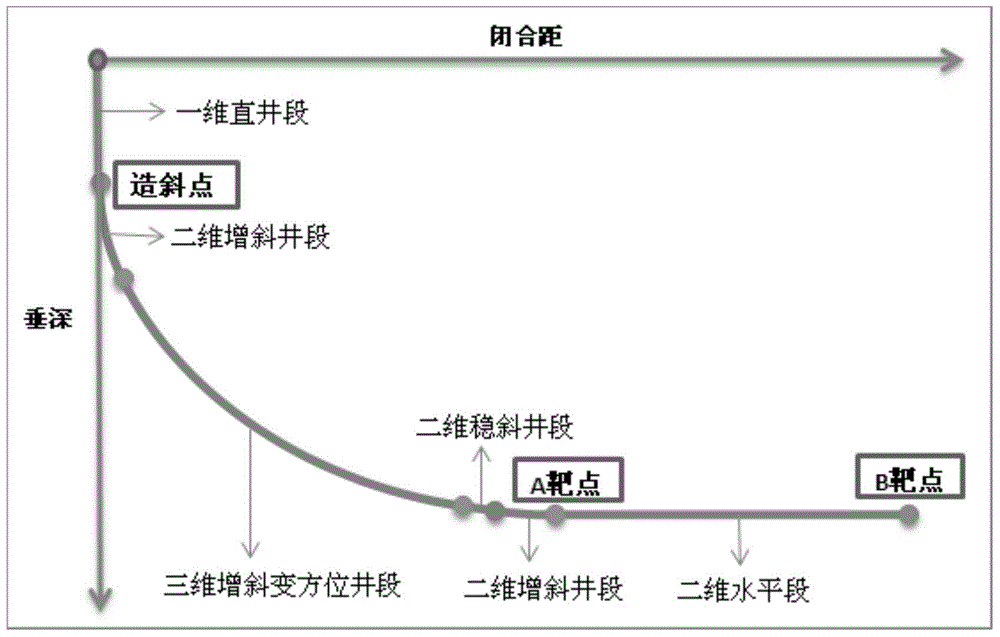

[0044] In this example, a three-dimensional horizontal well in a heterogeneous reservoir in Jinghe Oilfield is used as the construction object, and the ZJ40 drilling rig is used without top drive. The vertical planing diagram of the well track is as follows figure 1 As shown, target point A is the starting point of the horizontal section of the borehole trajectory; target point B is the end point of the borehole trajectory, and the drill tool assembly is "PDC bit + single curved screw + non-magnetic drill collar + measurement-while-drilling tool + righting Tool + Drill Collar + Heavy Drill Pipe + Ordinary Drill Pipe".

Embodiment 3

[0045] The three-dimensional horizontal well construction method of this embodiment is: the specific operation steps are:

[0046] 1) Correct the center points of the turntable, crown block and wellhead on the same vertical line, and the error is less than 5mm;

[0047] 2) Dig a circular well with a depth of 2.8 meters and a diameter of 3.2 meters, lower it into a circular iron bucket, and seal the annulus with cement concrete;

[0048] 3) Carry out drilling construction in the upper part of the one-dimensional vertical well section, the outer diameter of the drill bit is 311.2mm, the rotational speed of the drill bit is controlled at 90-95r / min, the displacement is 40L / s, and the drilling pressure is increased to 2-4 tons, and the Quaternary loess is drilled The soft layer entered the diagenetic formation with a vertical depth of 100 meters, and the well depth was 351.6m. Drilling was stopped and the wellbore was kept stable with heavy mud. Well cement mud 22.1m 3 , replace p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com