Patents

Literature

60results about How to "Full bore" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

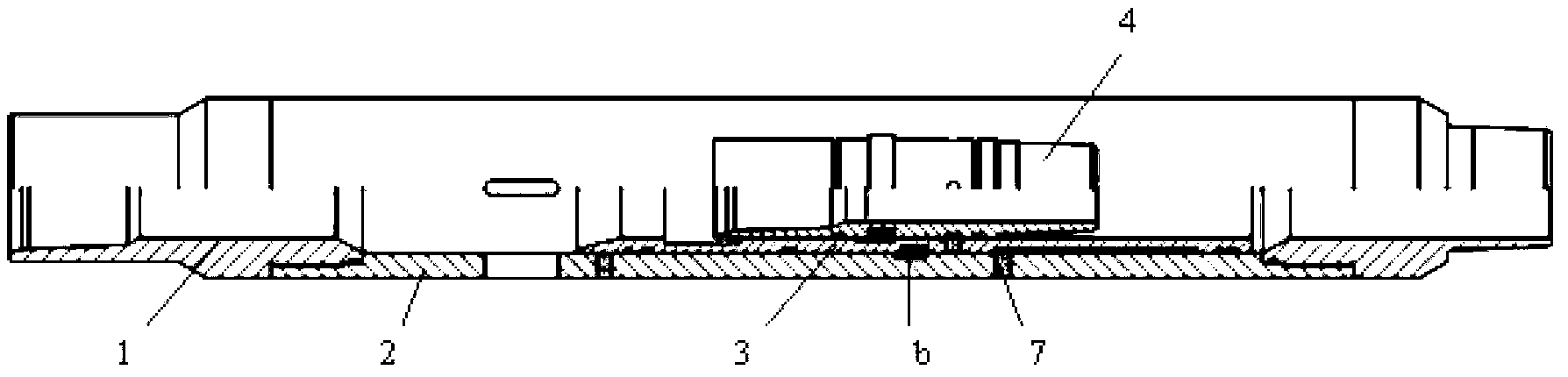

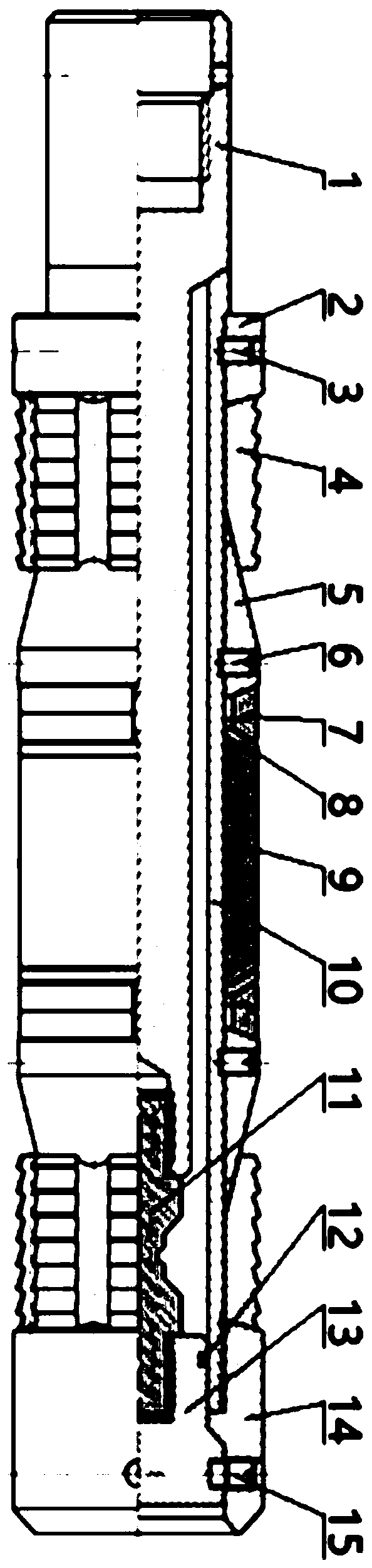

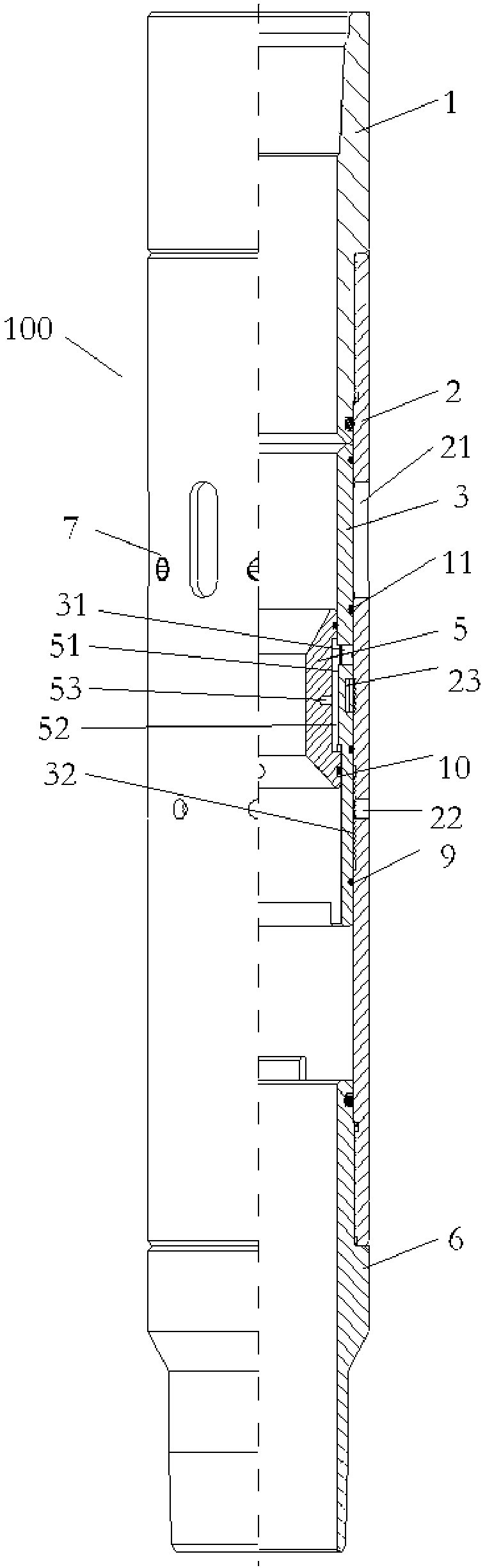

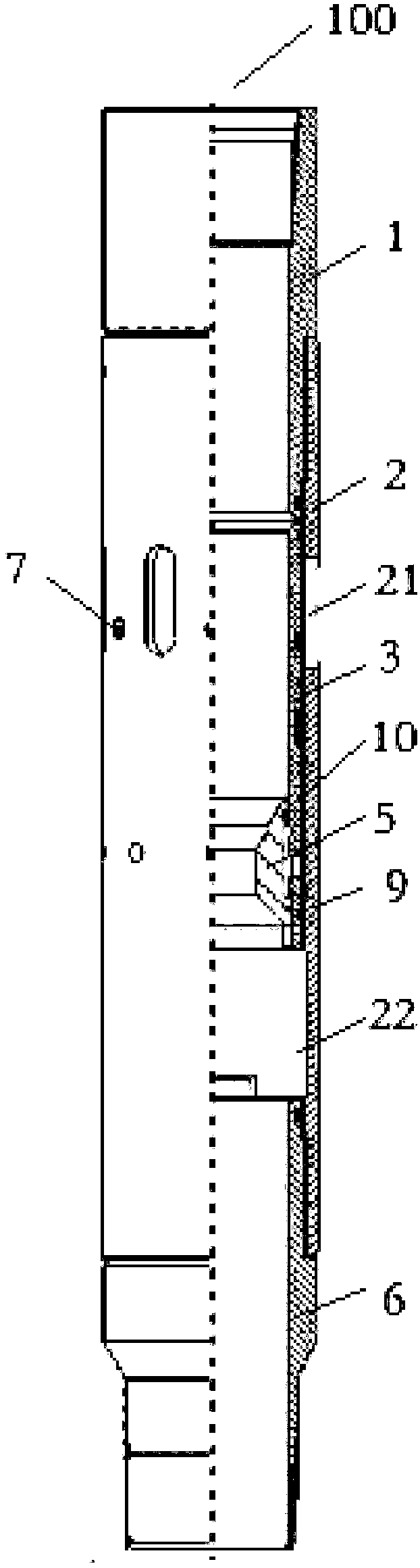

Variable-diameter fracturing valve

ActiveCN102337862AFull boreEasy to drillFluid removalWell/borehole valve arrangementsUpper jointEngineering

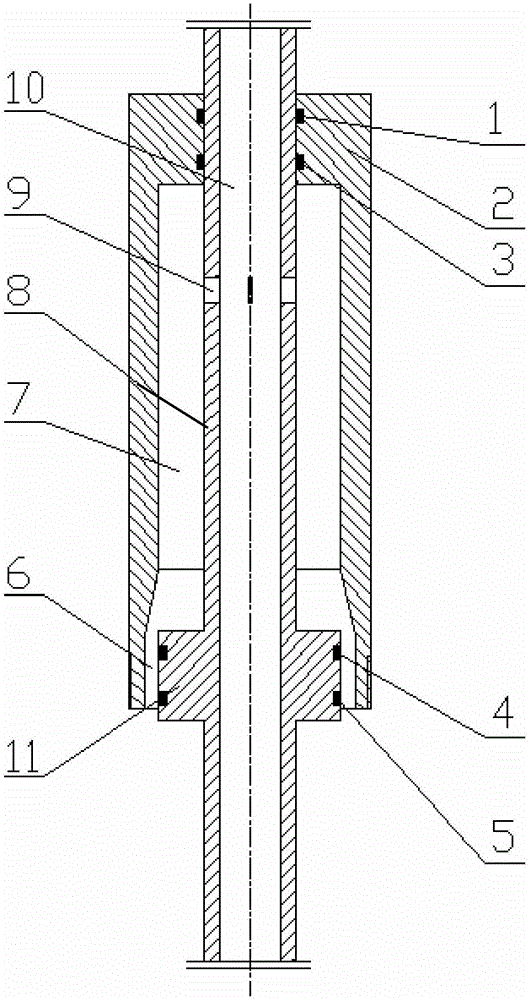

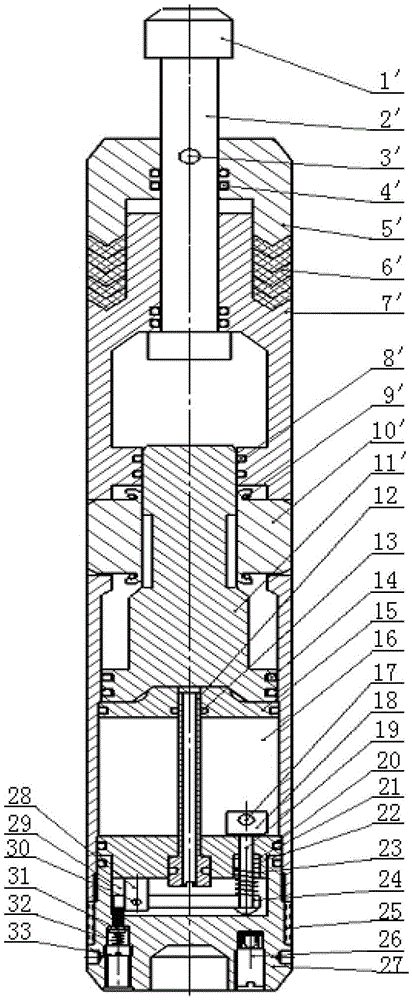

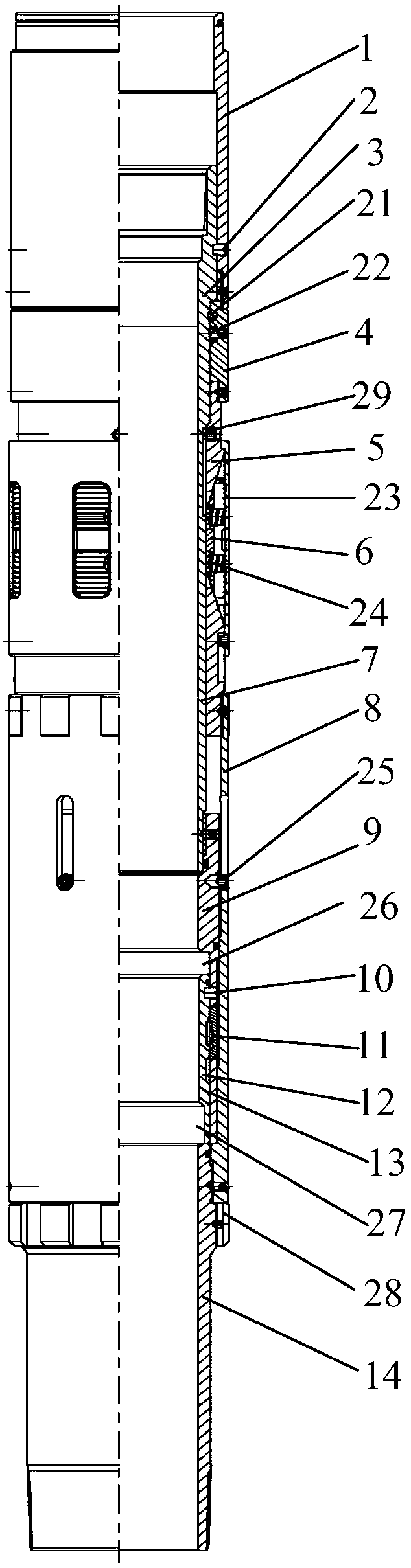

The invention relates to a variable-diameter fracturing valve, which is applied to modification construction of oil gas field fracturing. An upper pressure transmitting joint is fixed on the top of an upper pressure transmitting channel; an upper joint is provided with an axial fracturing channel, and an outer sliding sleeve and an inner sliding sleeve are arranged in the upper joint; the lower end of the upper joint is connected with a cylinder sleeve; an upper connecting cylinder is sleeved in the cylinder sleeve; a guide sleeve is sleeved in the upper connecting cylinder; the upper connecting cylinder is connected with the guide sleeve through a shearing pin; a supporting seat is in threaded connection with the upper connecting cylinder; the supporting seat is arranged in the upper connecting cylinder; a variable-diameter ball seat is arranged in the supporting seat; the cylinder sleeve is in threaded connection with a lower pressure transmitting body; the upper end of the lower pressure transmitting body is connected with a lower connecting cylinder; the lower pressure transmitting body is provided with a lower pressure transmitting channel, and the lower end of the lower pressure transmitting channel is provided with a lower pressure transmitting joint; and the lower end of the lower pressure transmitting body is connected with a lower joint. The variable-diameter fracturing valve has the effects that: the variable-diameter ball seat is drawn down sequentially to form a ball seat in the fracturing process; sealing balls with the same diameter are input repeatedly, and the fracturing valve is opened to sequentially complete fracturing repeatedly; and the variable-diameter fracturing valve is not limited by a borehole diameter and realizes unlimited section fracturing construction of laying down a row of pipe columns.

Owner:PETROCHINA CO LTD

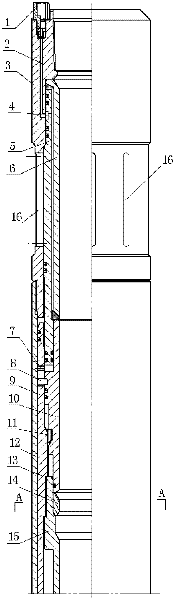

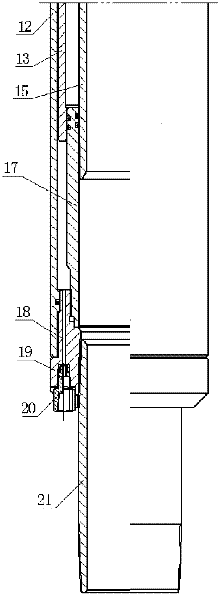

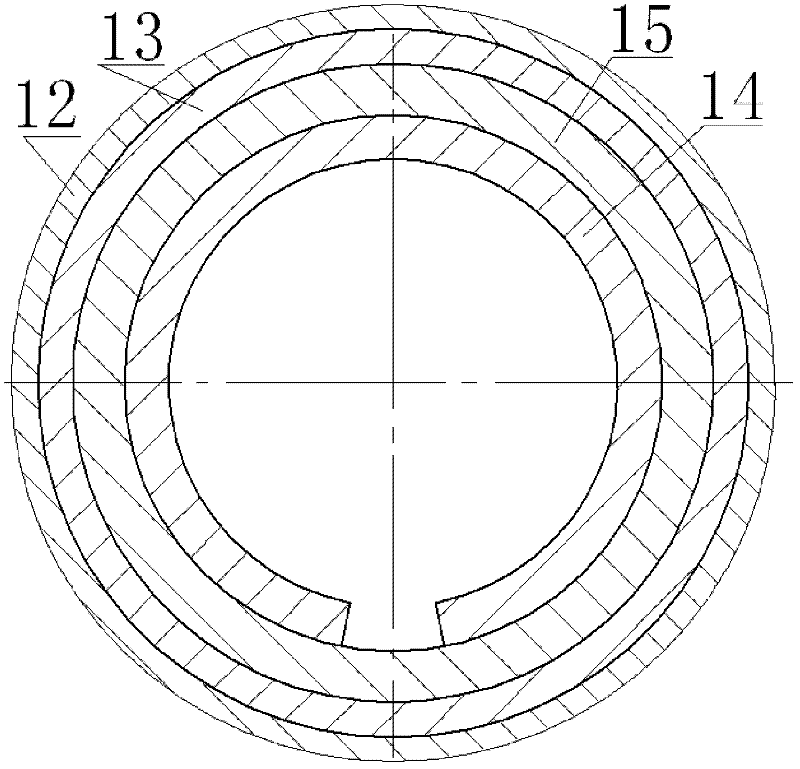

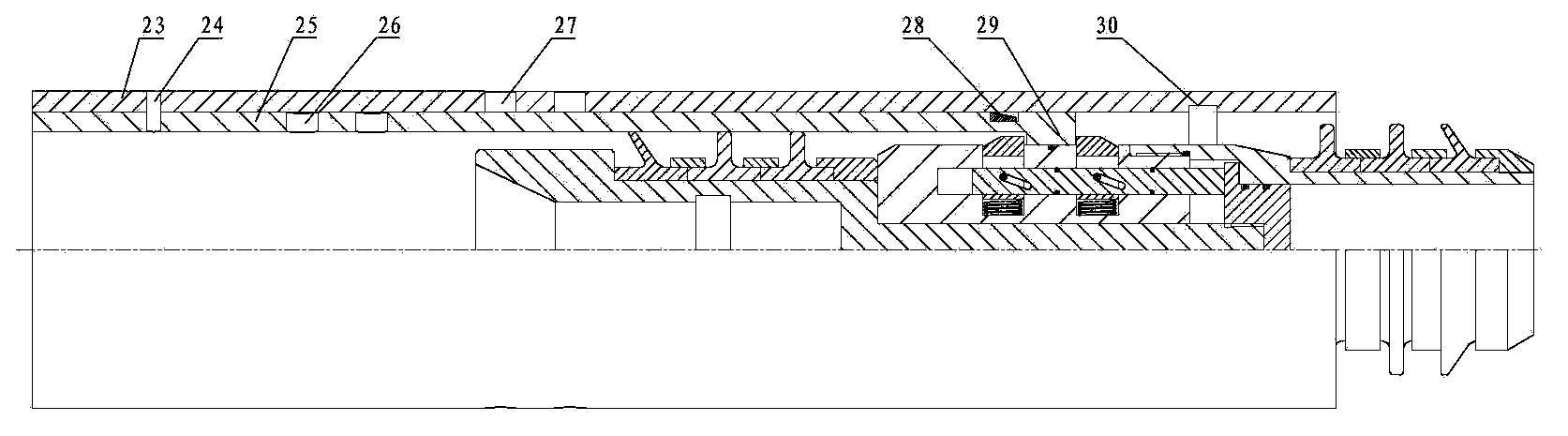

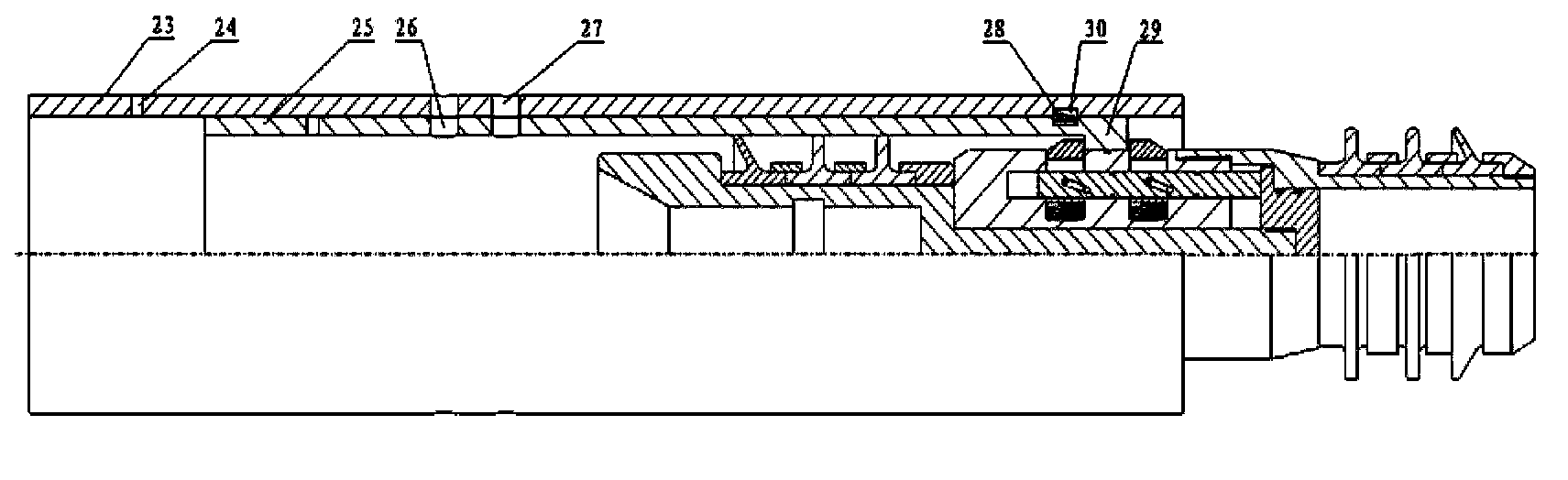

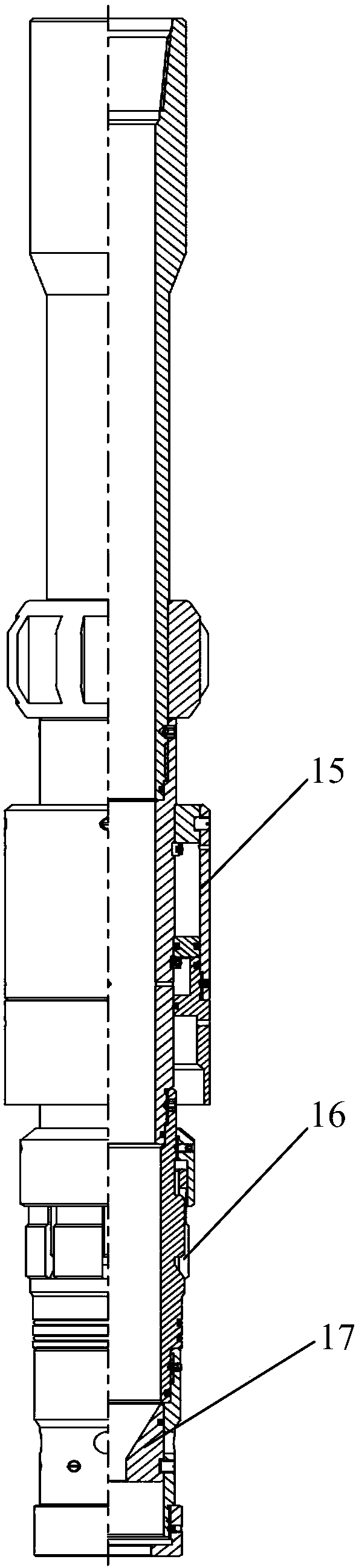

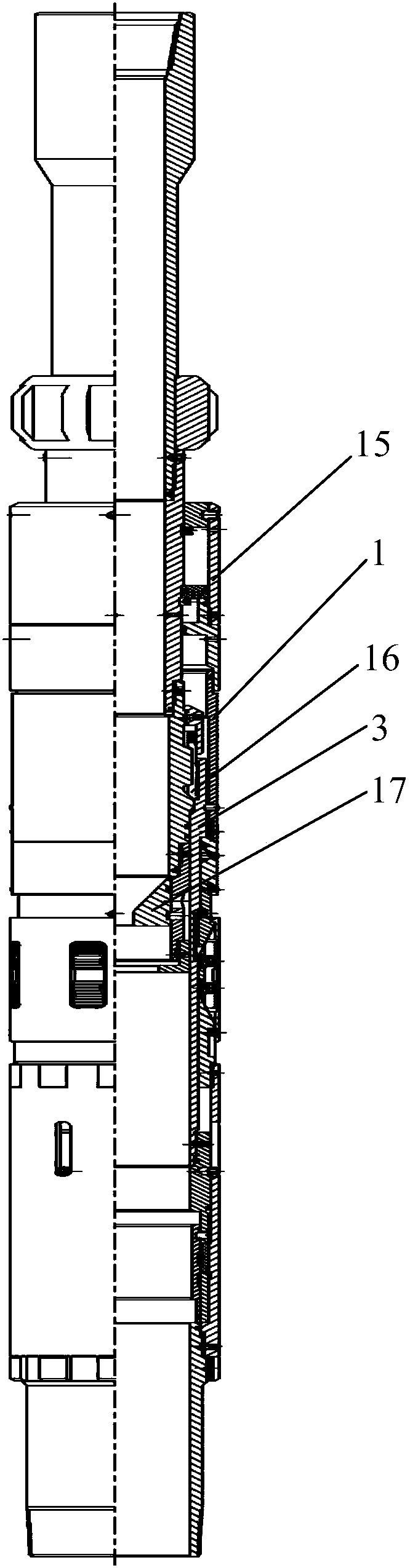

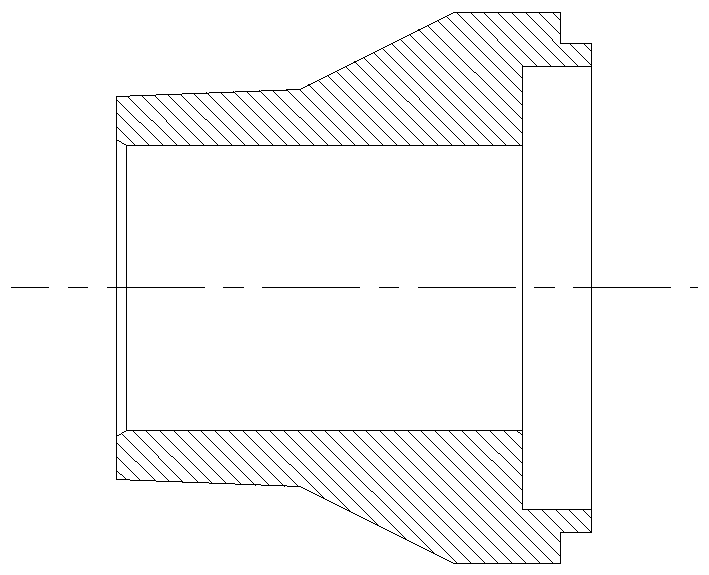

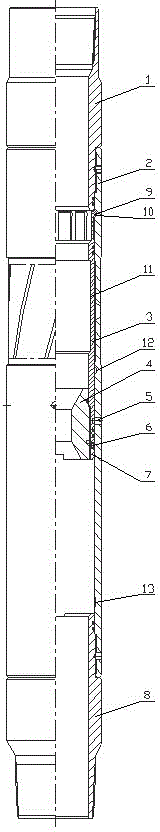

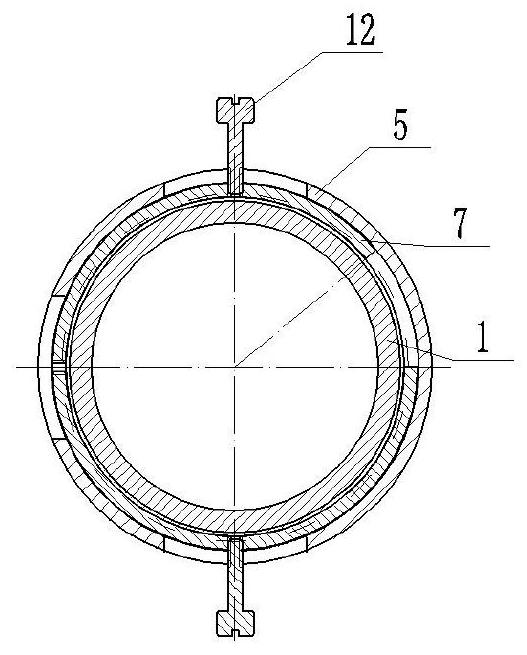

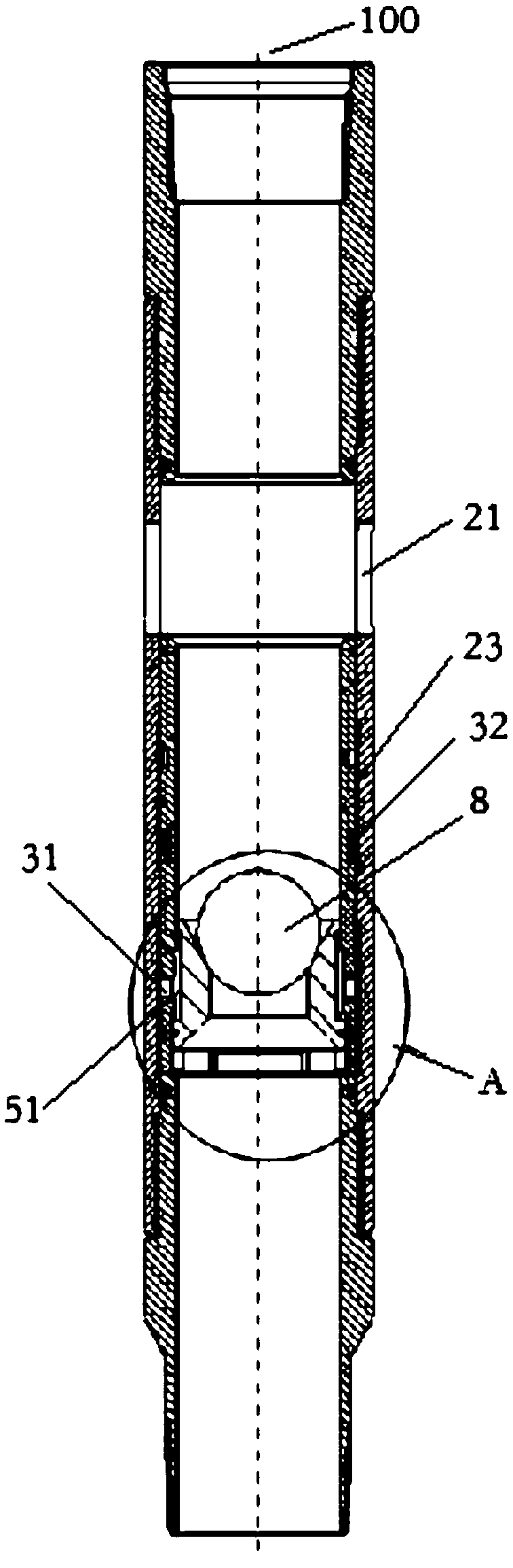

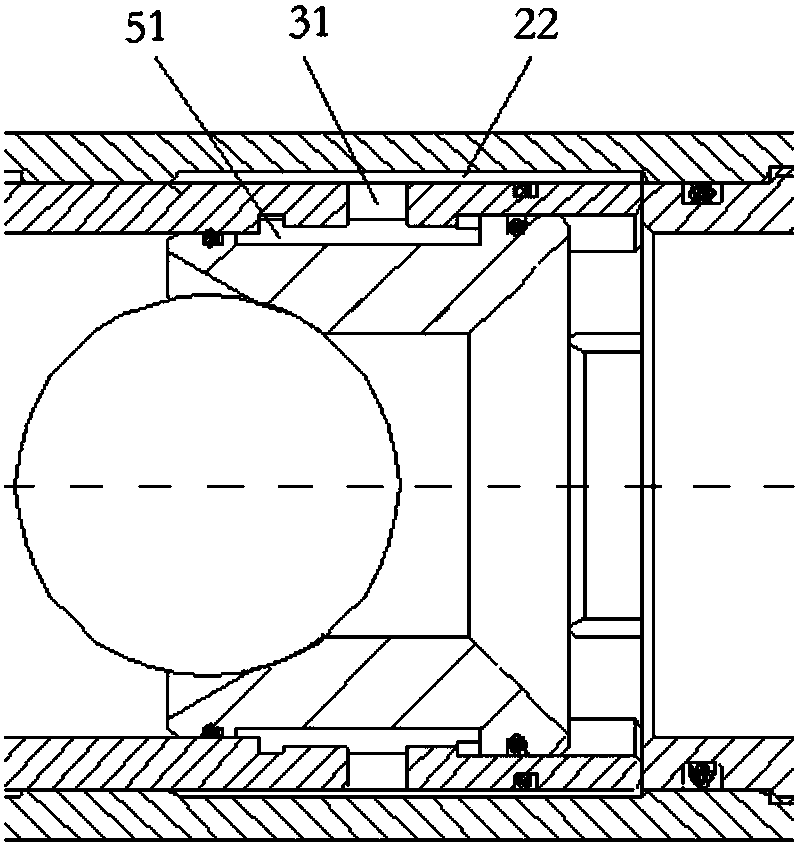

Sliding sleeve opening and closing device

The invention relates to a sliding sleeve opening and closing device comprising a stepped-shaft-shaped cylinder body and a locking block assembly installed at a first end of the body. A cylindrical supporting sleeve is arranged at the downstream of a shell, and an end cover is arranged between the supporting sleeve and the body. According to the sliding sleeve opening and closing device, the opening series of a sliding sleeve is not limited, flow-back is convenient, and working performance is reliable.

Owner:CHINA PETROLEUM & CHEM CORP +1

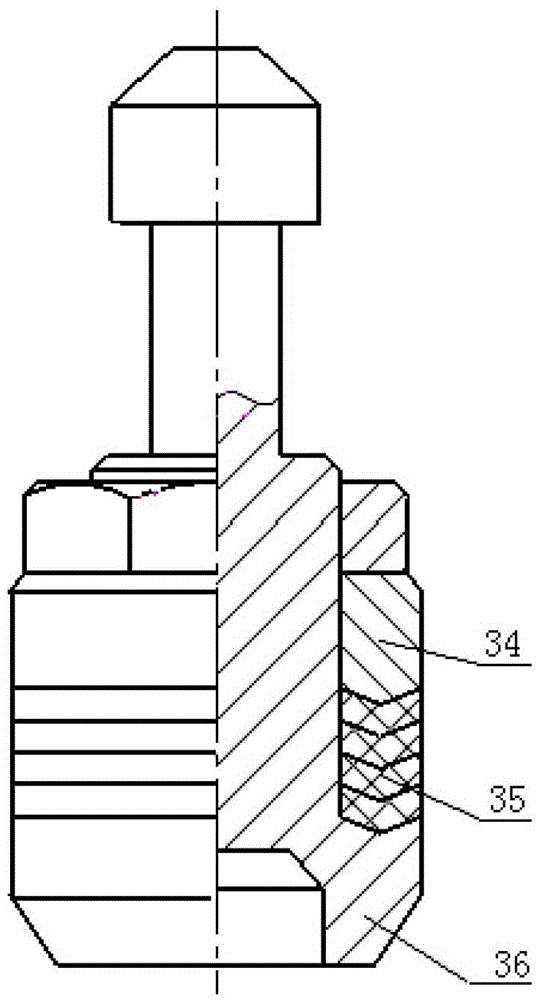

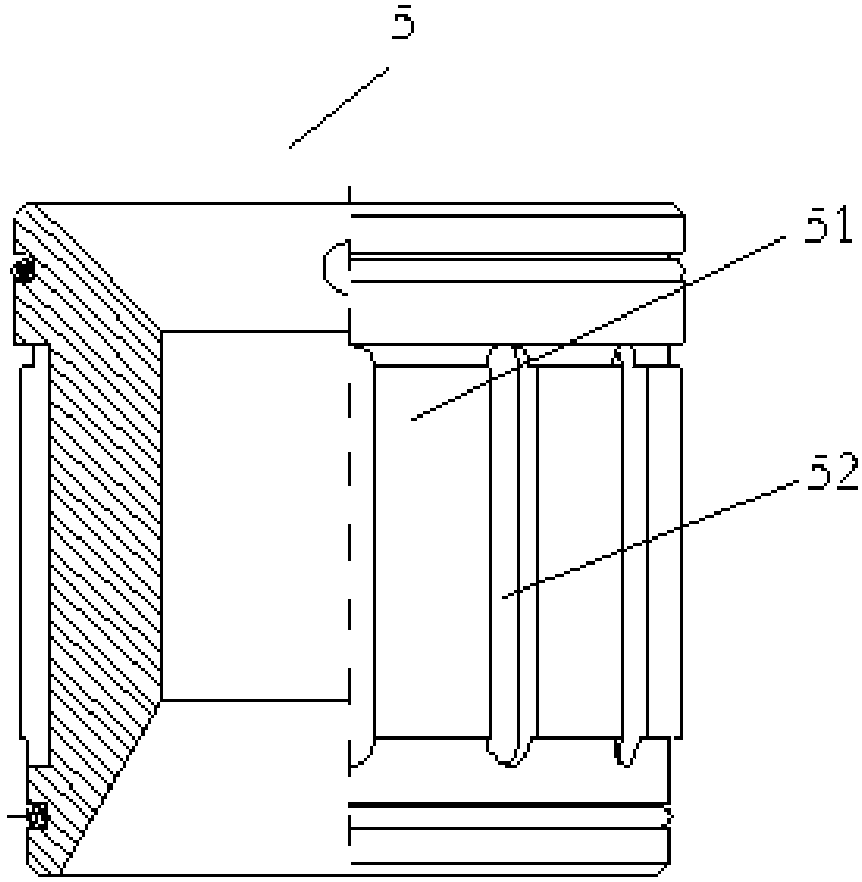

Threaded sliding sleeve with ball seat capable of being taken out

ActiveCN103321624ASmoothly down toNot easy to fall offFluid removalWell/borehole valve arrangementsEngineering

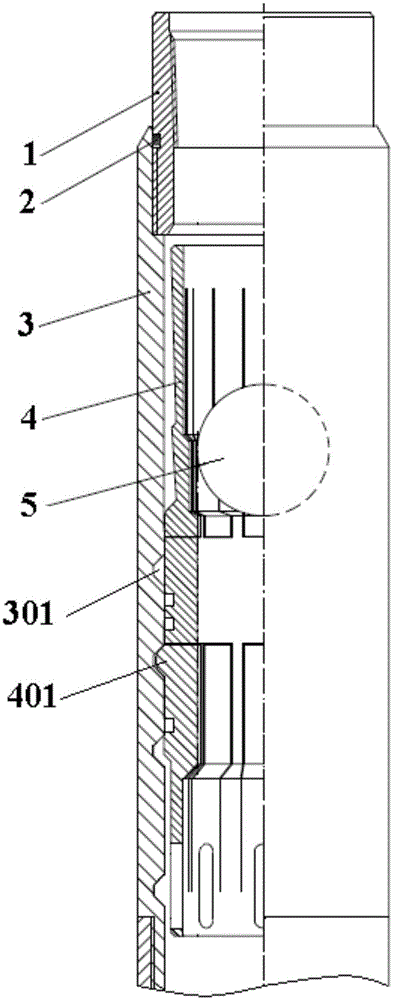

The invention discloses a threaded sliding sleeve with a ball seat capable of being taken out. The threaded sliding sleeve comprises a sliding sleeve body, an inner sliding sleeve and a ball seat cylinder, wherein the sliding sleeve body is composed of an upper connector, an outer cylinder and a lower connector, a fluid outlet hole is formed in the upper portion of the outer cylinder, and a clamp spring hole is formed in the lower position of the middle of the inner wall of the outer cylinder; a switch clamp groove is formed in the inner wall of the upper portion of the inner sliding sleeve, a locking ring groove is formed in the inner wall of the middle of the inner sliding sleeve, a locking ring is fixed at the lower portion of the locking ring groove, the length of the locking ring is smaller than that of the locking ring groove, a clamp spring is installed on the outer wall of the middle of the inner sliding sleeve, and an anti-rotating groove extending in the axial direction is formed in the outer wall of the lower portion of the inner sliding sleeve; a sliding sleeve shear pin is installed at the position, corresponding to the lower end of the anti-rotating groove, on the outer cylinder, and the upper end of the sliding sleeve shear pin stretches into the anti-rotating groove; threads are formed on the inner side of the upper end of the ball seat cylinder and on the outer side of the lower end of the ball seat cylinder, the outer diameter of the lower end of the ball seat cylinder is the same with the inner diameter of the upper end of the ball seat cylinder, a ball seat locking ring groove is formed in the outer periphery of the ball seat cylinder, and the inner side of the locking ring stretches into the ball seat locking ring groove. Salvage of all ball seat cylinders in a tubular column can be achieved, and a full path of an underground pipe string is achieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

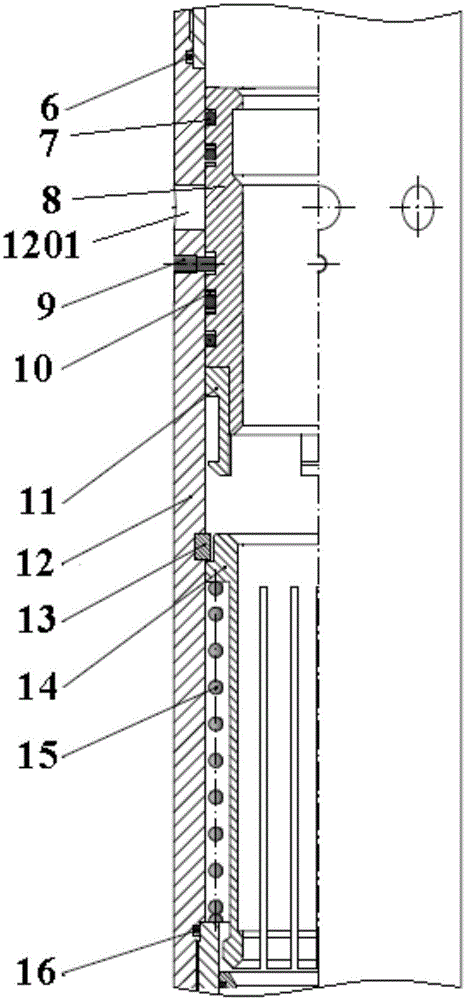

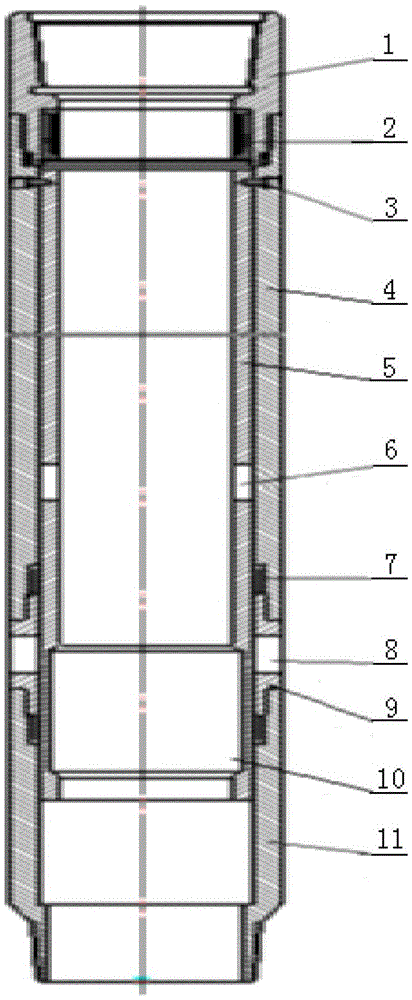

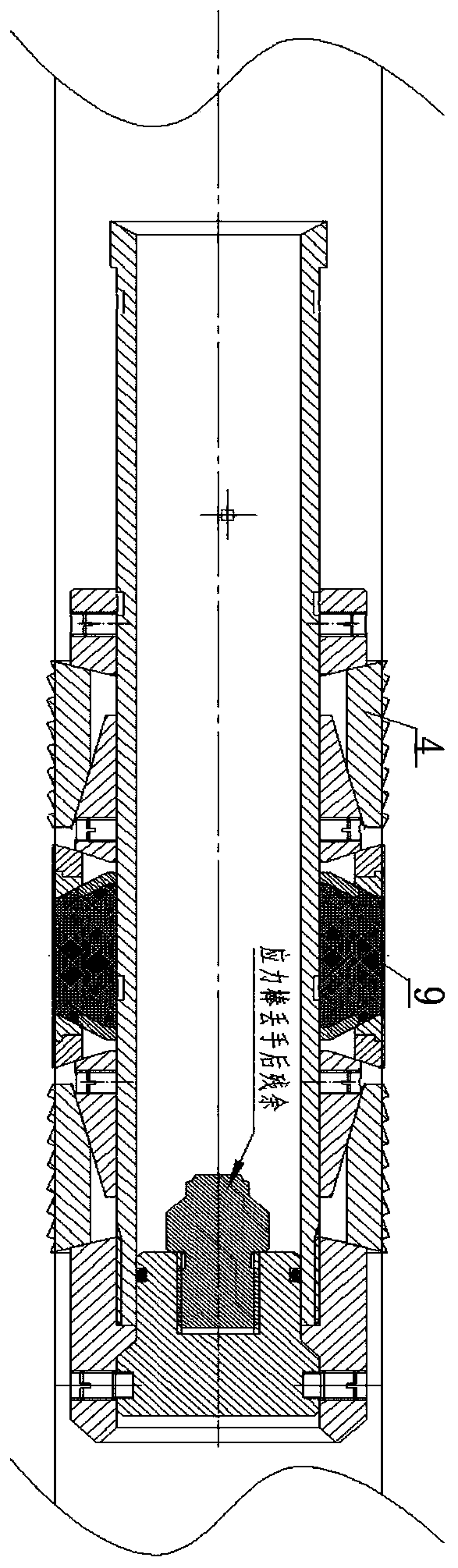

Single slip soluble bridge plug

The invention provides a single slip soluble bridge plug. The single slip soluble bridge plug includes a central pipe, wherein an upper joint, a rubber cylinder, a cone, a slip mechanism and a lower joint are sequentially arranged on the central pipe in a sleeving mode, and the upper joint, the rubber cylinder, the cone and the slip mechanism can slide in the axial direction of the central pipe; the upper joint is connected with the central pipe through a shear pin; the small diameter end of the cone is inserted into a gap between the slip mechanism and the central pipe; the slip mechanism includes a first slip tooth and a second slip tooth, the tip of the first slip tooth inclines towards one side of the upper joint, and the tip of the second slip tooth inclines towards one side of the lower joint; and the central pipe, the upper joint, the lower joint, the cone and the slip mechanism are made of soluble metal materials, and the rubber cylinder is made of a soluble elastic material. The single slip soluble bridge plug adopts a single slip structure, is shorter in length, small in size, the bridge plug goes down conveniently when plugging, and anchoring reliability is high; and after stratified fracturing is completed, the single slip soluble bridge plug can be dissolved by a flow back fluid, the dissolution rate is fast, so that the full bore of a wellbore after fracturing canbe realized, and the flow back efficiency is enabled to be high.

Owner:FIVE STAR DOWNHOLE SERVICE INC +1

Method for temporary plugging and layering reconstruction of gas well and application

InactiveCN108343417AReduce usageReduce processFluid removalSealing/packingCable transmissionMaterial Perforation

The invention provides a method for temporary plugging and layering reconstruction of a gas well and an application, and belongs to the field of low-permeability gas reservoir reconstruction. According to the method, after cable transmission perforates under pressure, a perforating gun is lowered below 10 meters from a perforation section of a layer, a cable of a wellhead is kept under pressure, fracturing / acidizing reconstruction is carried out, a soluble temporary plugging agent is pumped in a displacement fluid stage, and the perforating gun is lift to a second reconstruction point after judging the success of temporary plugging, the steps are repeated until the reconstruction of the well is completed, the perforation gun is lifted up, and liquid is discharged after the temporary plugging agent is dissolved. According to the method, fracturing is carried out after the perforating gun is lowered after perforation, and no packer drilling tool is arranged in a pitshaft, the soluble temporary plugging agent is used for realizing interlayer isolation, infinite layered fracturing reconstruction can be realized, a large drift diameter can meet the requirements of the concept of large displacement reconstruction of reservoirs in recent years, after measures are taken, the full diameter of the pitshaft is also convenient for subsequent pitshaft operations, the operation flow is simple, the cost is reduced, and the efficiency is increased.

Owner:PETROCHINA CO LTD

Completion technology method for sidetracked well

ActiveCN111472690AImprove pressure bearing capacityFull boreFluid removalSealing/packingWell drillingWell cementing

The invention provides a completion technology method for a sidetracked well. A tail pipe suspension and tie-back integrated tool is installed on the upper portion of a small-diameter casing pipe, well cementation of the small-diameter casing pipe in an original well bore is completed, and a tie-back barrel is reserved on the upper portion of the small-diameter casing pipe after suspension. Duringfracturing construction, a sealing insertion pipe and the small-diameter casing pipe can be connected and put into the sidetracked well, the sealing insertion pipe is inserted into the tie-back barrel to form a shaft similar to a new well, the full bore of the shaft of the sidetracked well is achieved, the pressure bearing capacity of the whole shaft is improved, and conditions are created for achieving multi-layer and section transformation and water-resisting oil extraction of a subsequent reservoir.

Owner:PETROCHINA CO LTD

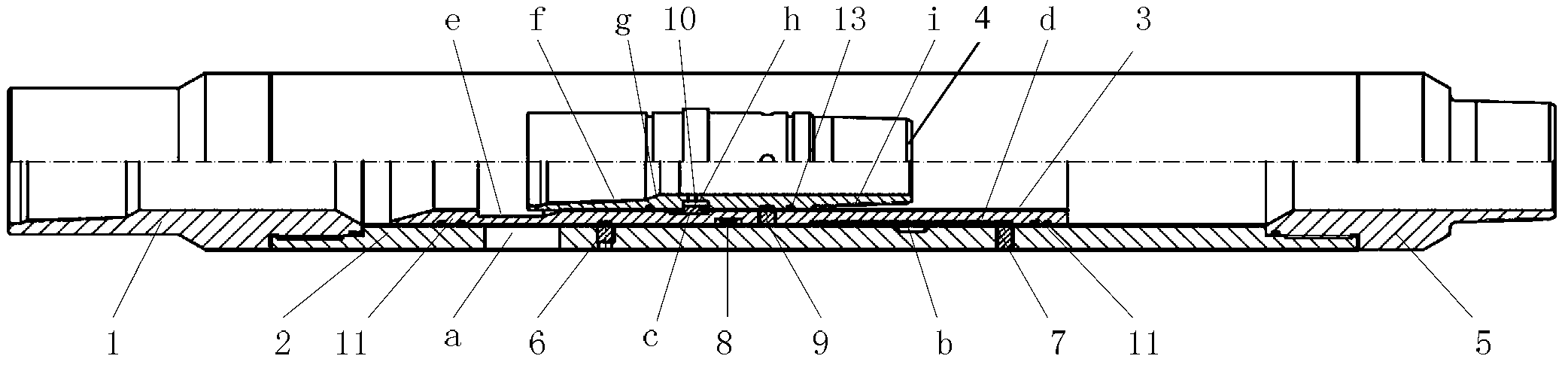

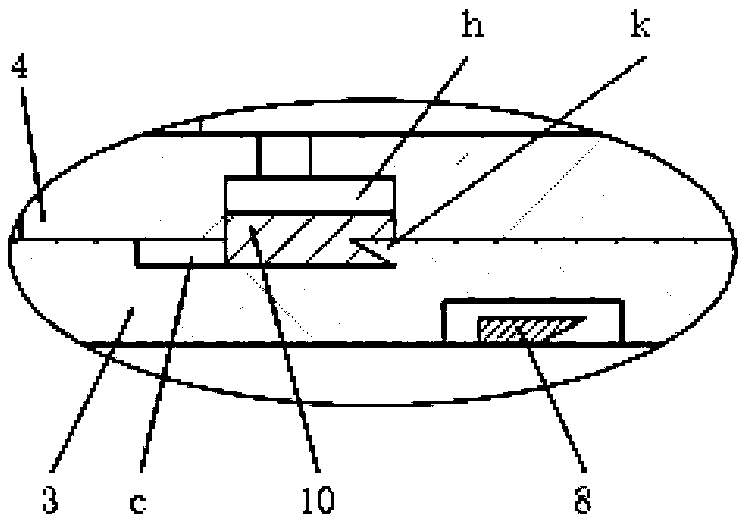

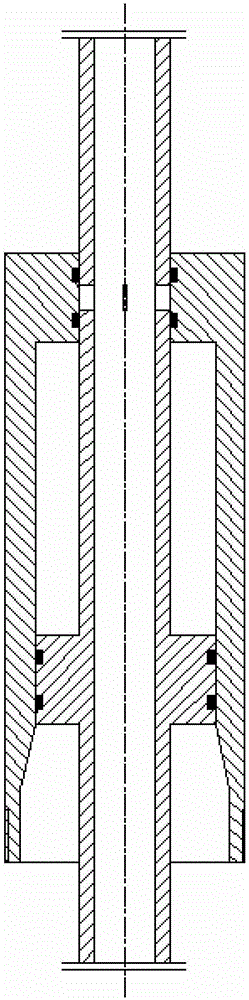

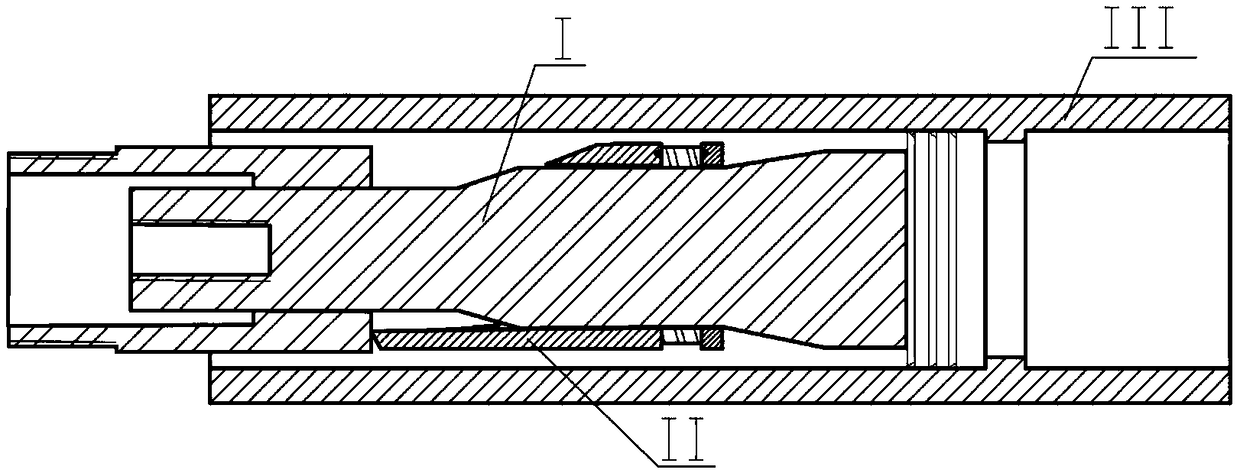

Multilayer testing sampling valve

ActiveCN106194108AFull boreDoes not affect connectivityWell/borehole valve arrangementsSealing/packingEngineeringSampling valve

The invention discloses a multilayer testing sampling valve. The multilayer testing sampling valve comprises a mandrel and a shell; the shell is shaped like a cylinder, a channel with a flared section is formed in the lower section of an inner cavity of the shell, a through hole matched with the outer diameter of the mandrel is formed in the top end of the shell, the mandrel with a main liquid channel penetrates through the through hole, two o-shaped sealing rings are embedded in the inner wall of the through hole, the sealing effect is achieved when the mandrel moves up and down in the through hole, a convex ring matched with the inner cavity of the shell is formed on the outer wall, on the lower half part, of the mandrel, two o-shaped sealing rings are embedded in the outer peripheral face of the convex ring, the mandrel, the convex ring and the inner cavity of the shell can form a closed sampling cavity, a mandrel side opening is formed in the side face of the upper portion of the mandrel, when the bottom of the convex ring is located at the bottom of the inner cavity above the flared section, the mandrel side opening is just located between the o-shaped sealing rings of the through hole in the top end of the shell, and the sampling cavity is a closed cavity. According to the multilayer testing sampling valve, switching-on and switching-off are only for a single layer and do not affect communication of a main runner.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

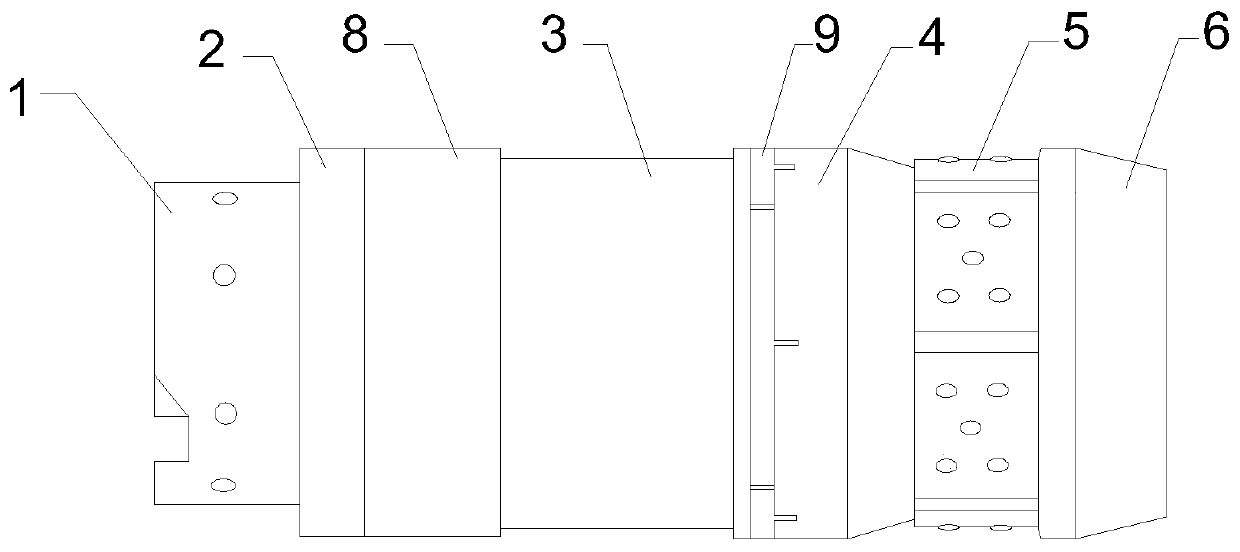

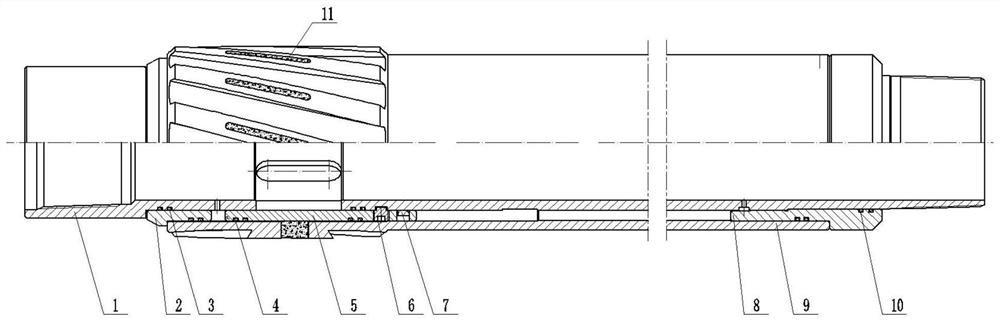

Fracturing sliding sleeve

ActiveCN106555568ASimple structureEasy to operateFluid removalWell/borehole valve arrangementsUpper jointPetroleum

The invention discloses a fracturing sliding sleeve, and belongs to the technical field of petroleum and gas mining equipment. The fracturing sliding sleeve comprises an upper joint, an upper pipe body, a lower pipe body, a transition pipe body, a lower joint, a counting sliding sleeve, a sliding sleeve spindle, a ball collection elastic claw, an elastic claw base and a blocking ball; the counting sliding sleeve is located in the upper pipe body and can axially move; multiple first positioning grooves are formed in the inner surface of the upper pipe body in the axial direction, and first positioning claws matched with the first positioning grooves are arranged on the outer surface of the counting sliding sleeve; the upper end of the ball collection elastic claw is located at the lower end inside the lower pipe body, and the lower end of the ball collection elastic claw is located at the upper end inside the transition pipe body and can axially move; the elastic claw base is located under the ball collection elastic claw, and the ball collection elastic claw can enter the elastic claw base; the initial inner diameter of the ball collection elastic claw is larger than the diameter of the blocking ball, and the inner diameter of the ball collection elastic claw entering the elastic claw base is smaller than the diameter of the blocking ball. By adopting the fracturing sliding sleeve, different levels of underground sliding sleeves can be opened layer by layer through the blocking balls with the same size, and then full bore perforating of underground pipe strings is achieved.

Owner:PETROCHINA CO LTD

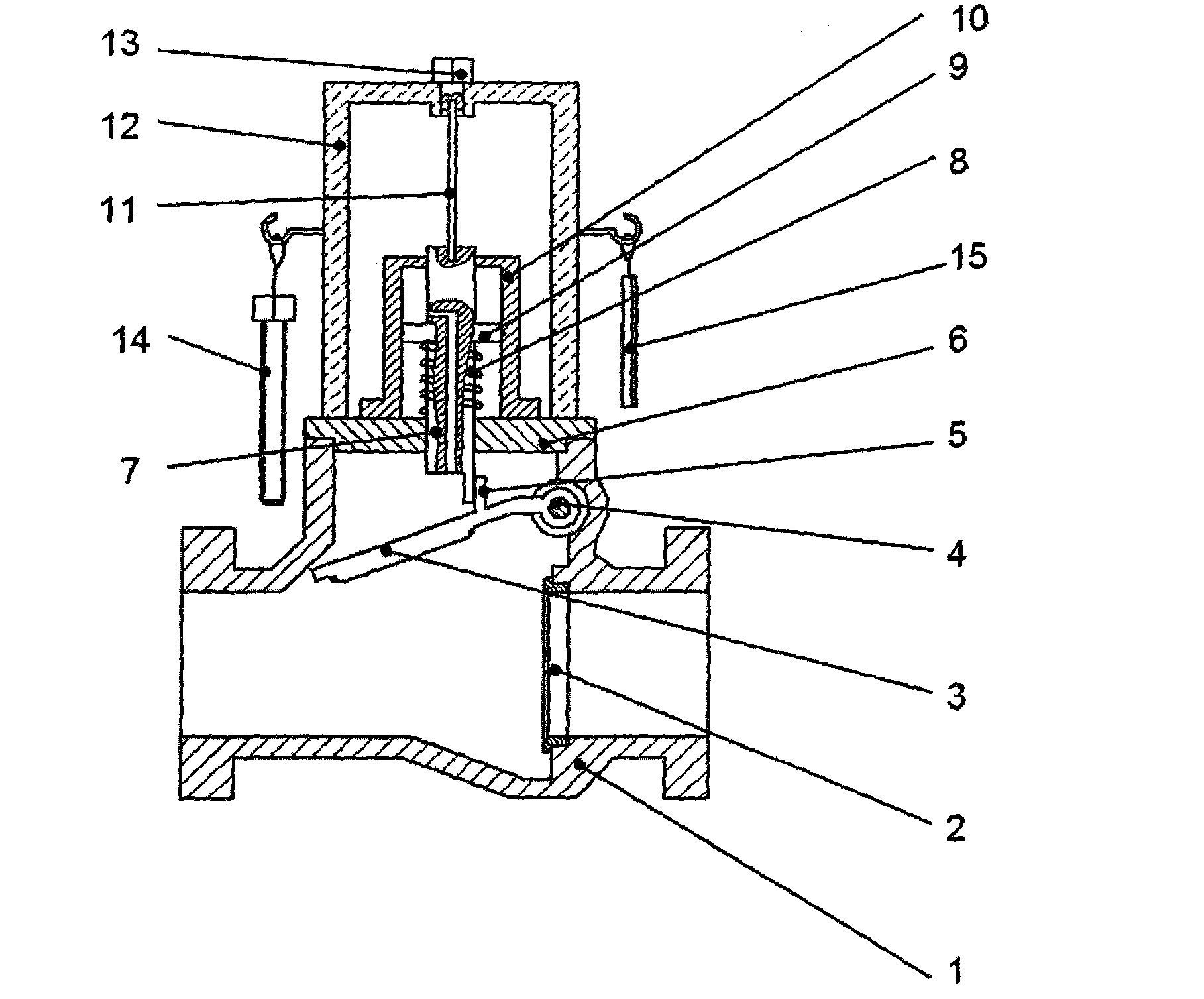

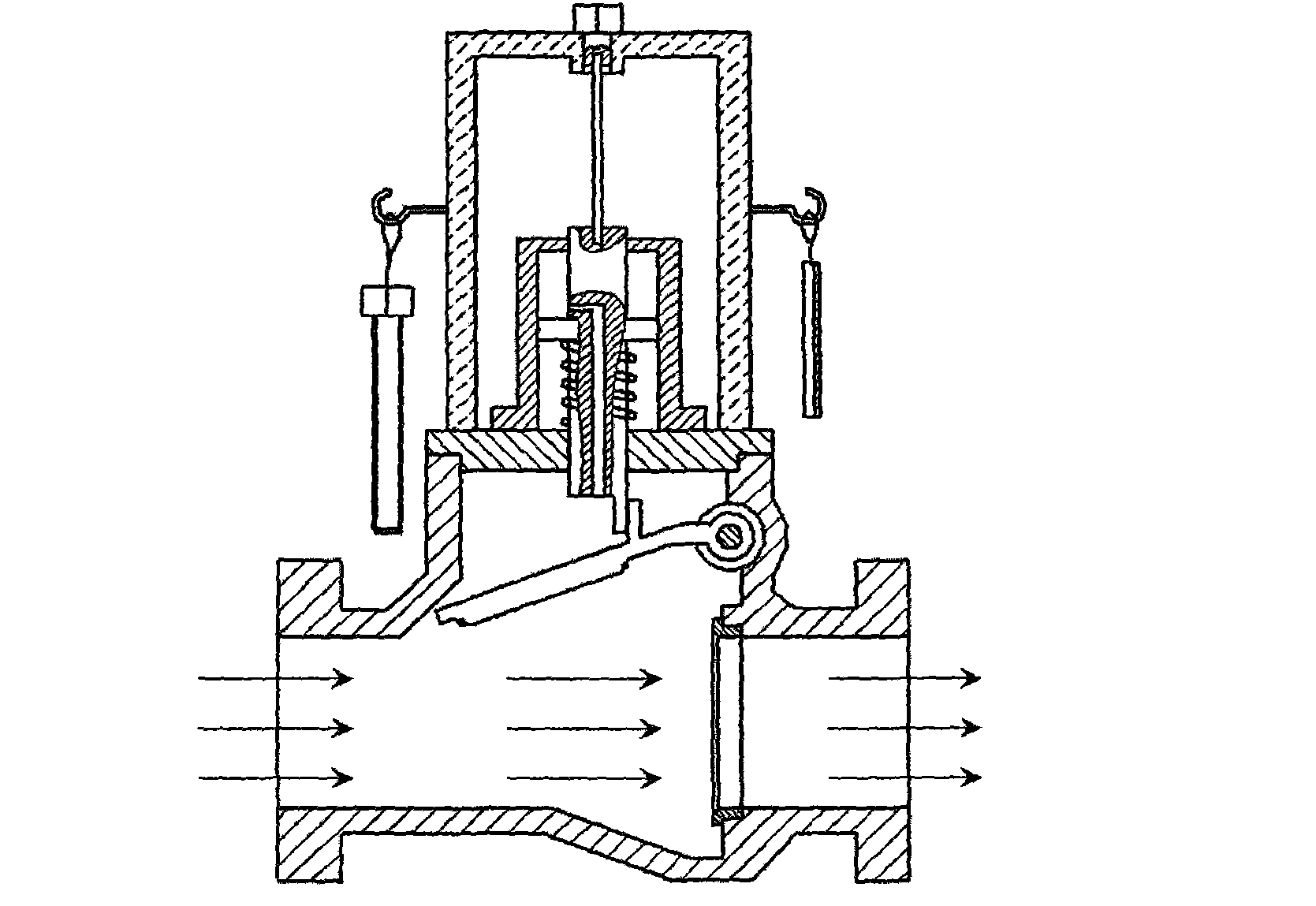

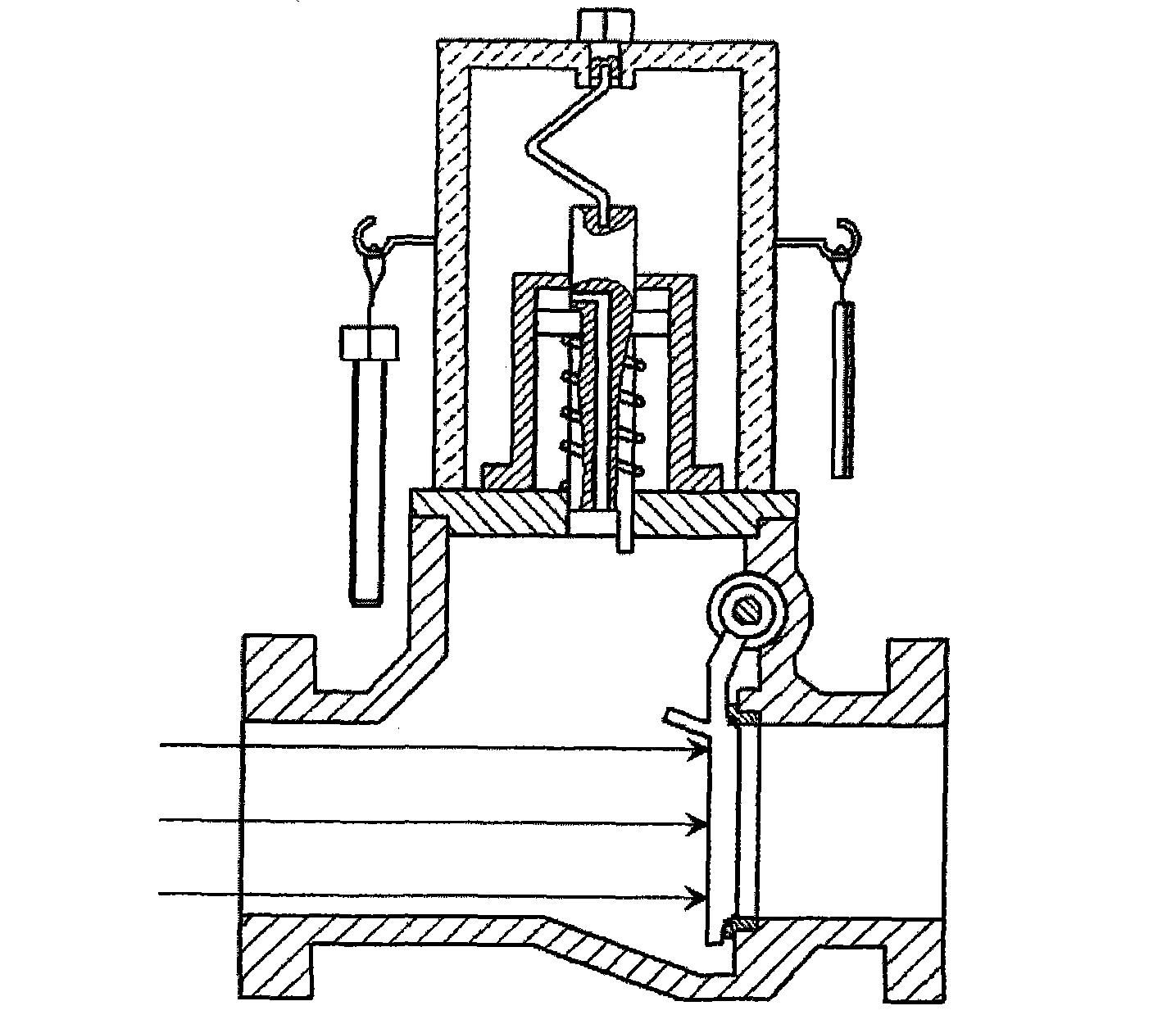

Novel low-pressure triggering pressure lever instability shut-off valve

InactiveCN103470218AHigh trigger accuracyEasy to cleanWell/borehole valve arrangementsSealing/packingCritical loadEffective length

The invention relates to a novel low-pressure triggering pressure lever instability shut-off valve, which comprises the following main components: a valve body, a valve seat, a valve clack, a rotating shaft, a valve cover, a valve rod, a spring, a piston, an air cylinder, a slender rod, a rod cage, a rod cap and the like, wherein the slender rod is a triggering component for shutting off a valve, and is designed according to the principle of pressure lever instability. When the pressure in a pipeline is higher than a specified point, a supporting force borne by the slender rod is lower than the pressure lever instability critical load of the slender rod, a pressure lever is kept stable, a valve clack catch is clamped at the lower end of the valve rod, and the valve is kept to be in the open state. When the pressure in the pipeline is lower than the specified point, the axial load borne by the slender rod exceeds the pressure lever instability critical load of the slender rod, the pressure lever is instable, the effective length of the pressure lever is instantaneously reduced, and at the moment, the valve clack catch is separated from the lower end of the valve rod, the valve clack rotates around the rotating shaft under the action of gravity, and the valve is closed under the push of fluid. The valve is simple in structure, is only provided with three moving components, and is very higher in reliability.

Owner:JIANGSU RELIABLE MECHANICAL EQUIP CO LTD

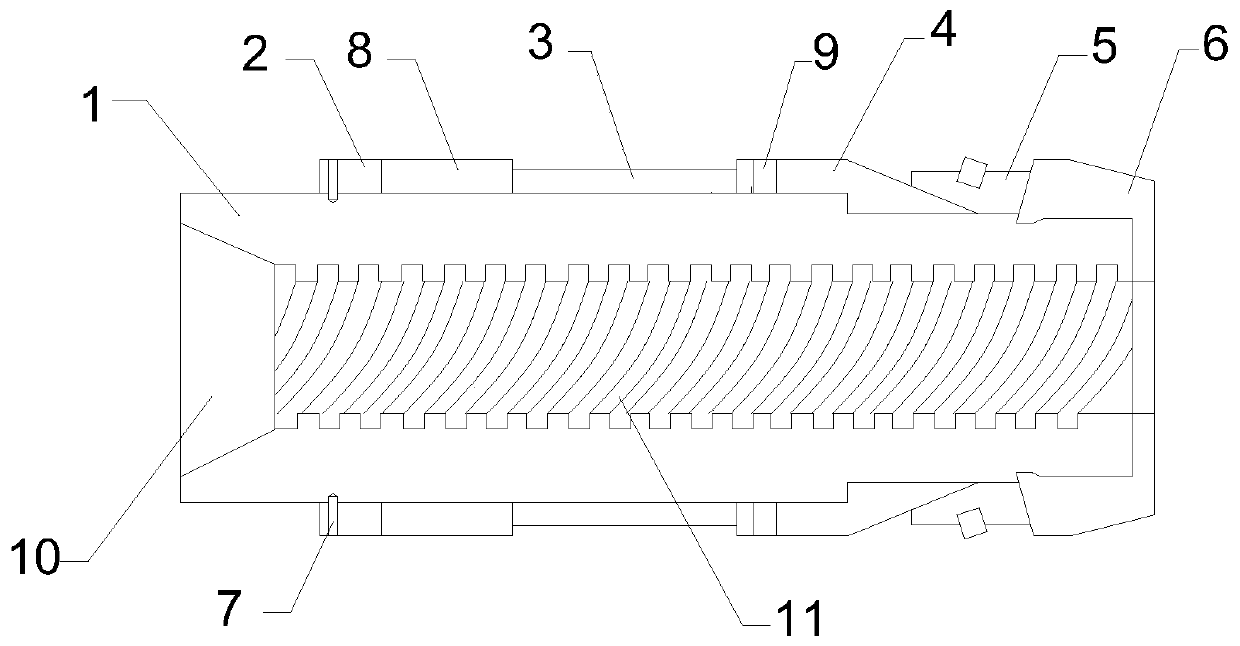

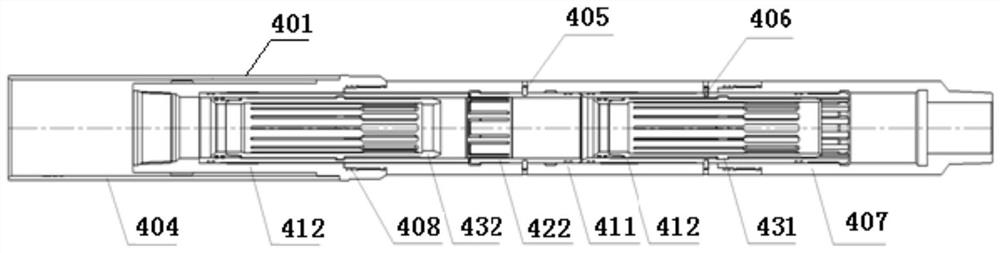

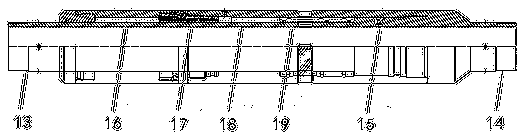

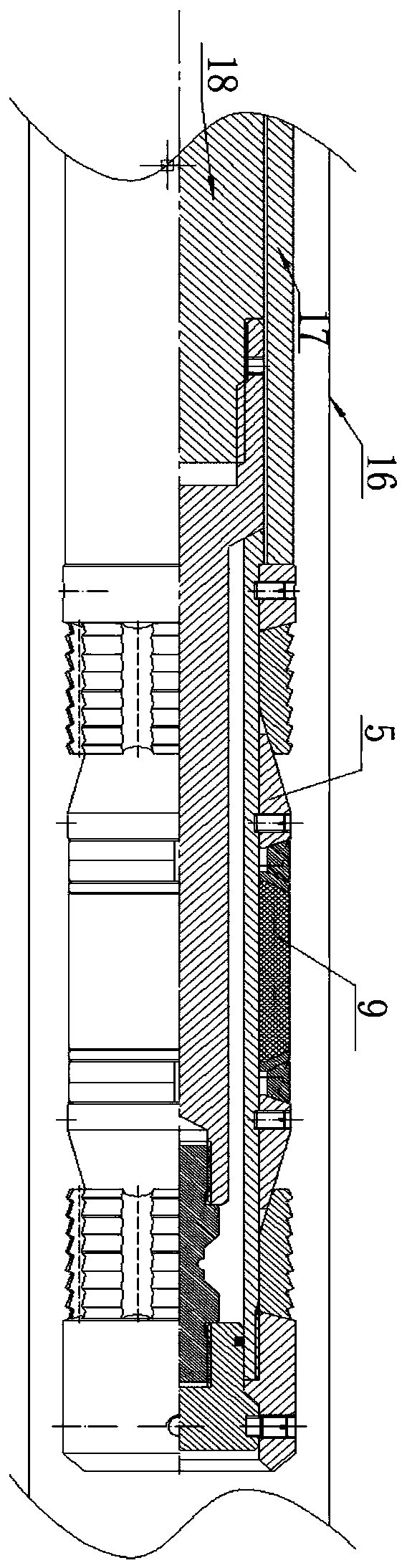

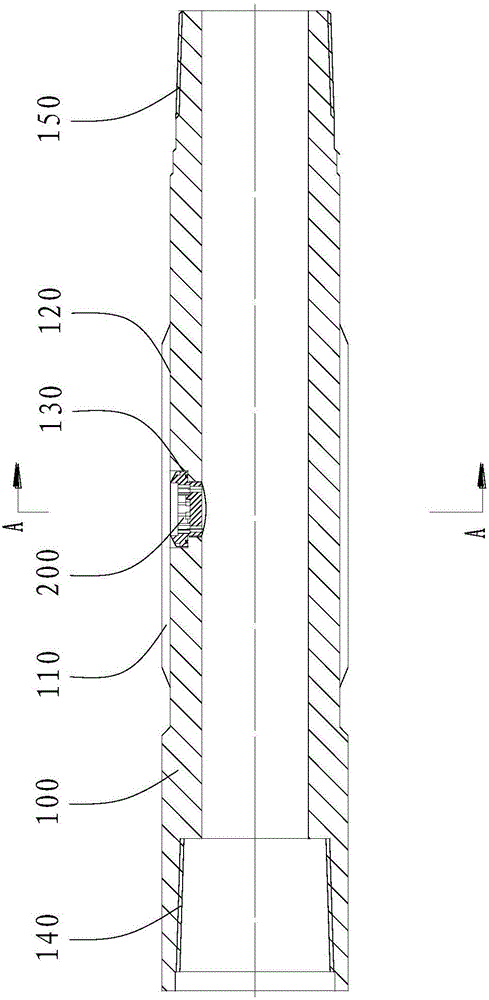

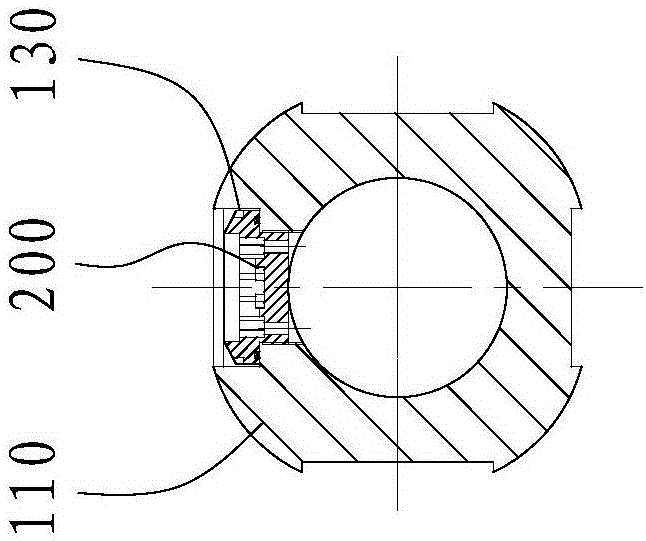

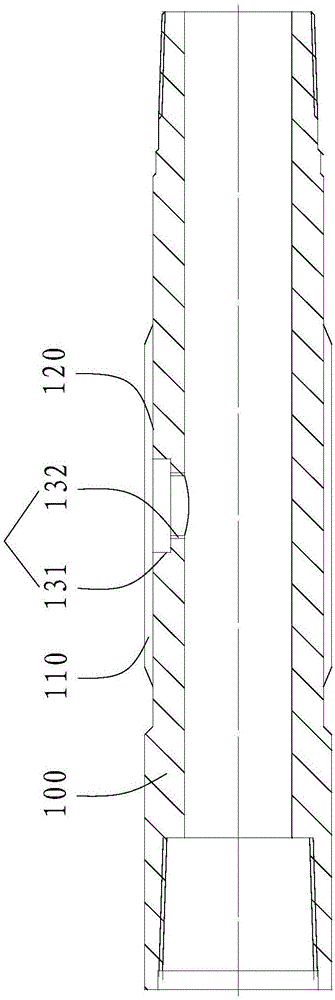

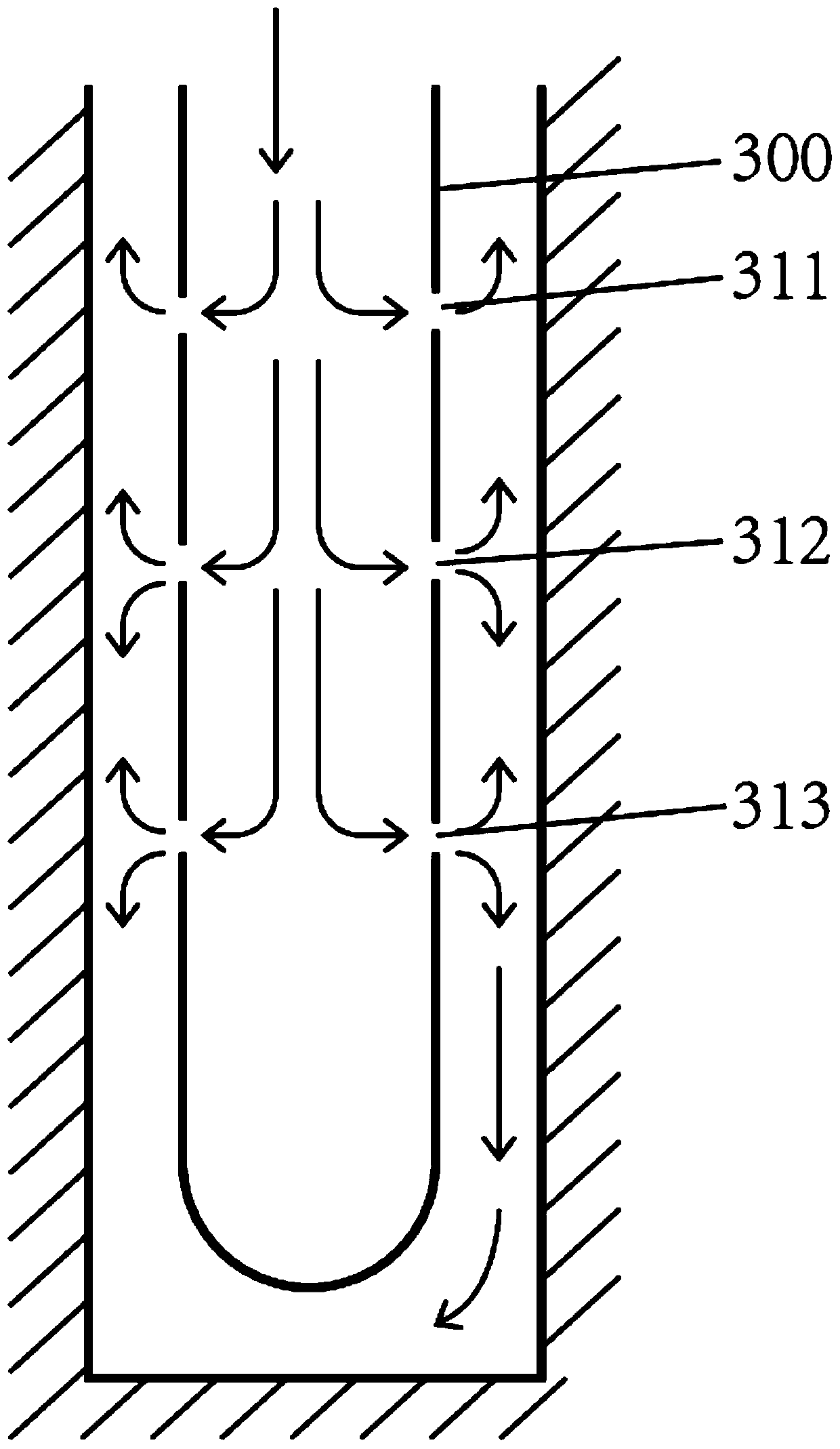

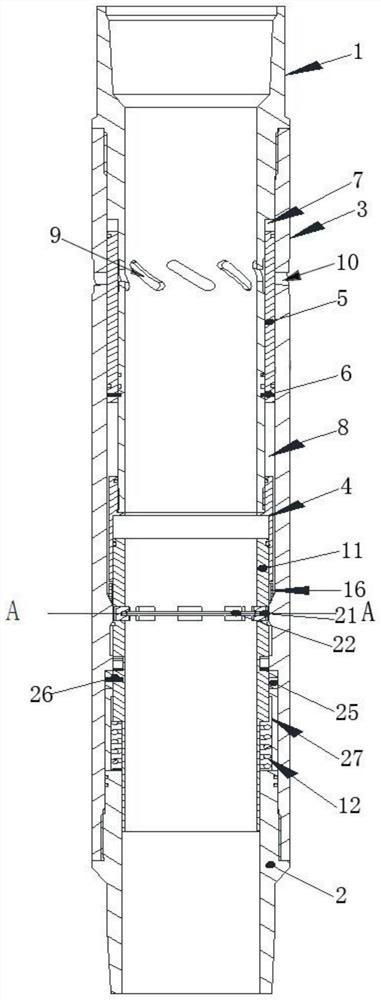

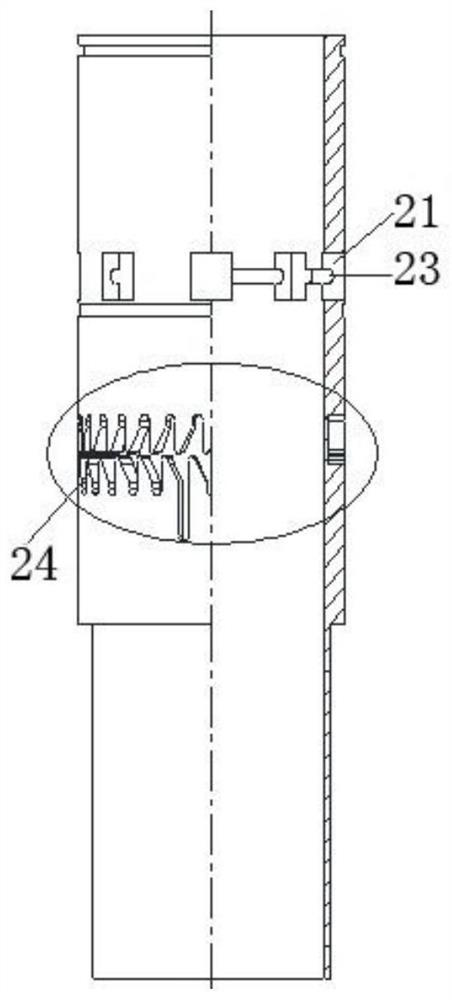

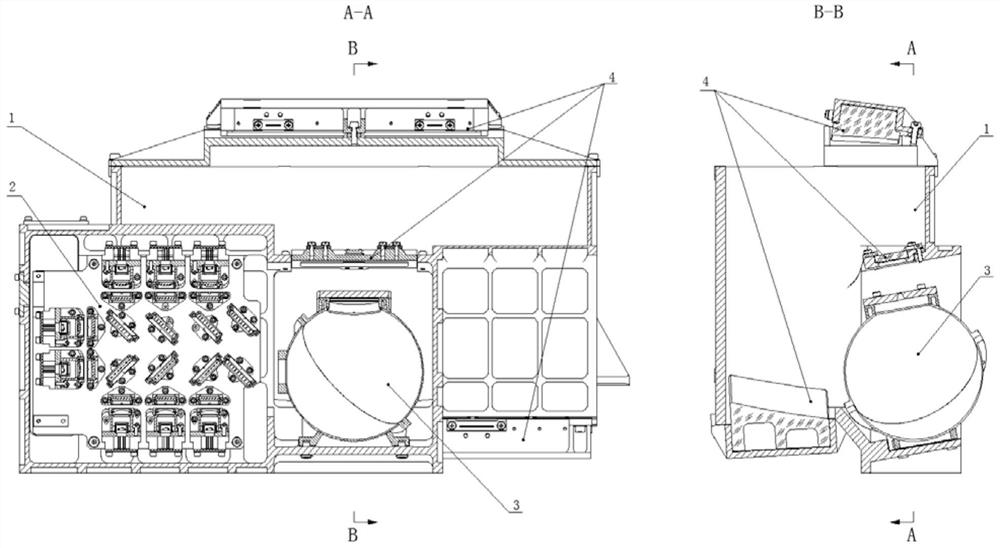

Unlimited-level full-bore staged fracturing sand prevention pipe column and production method thereof

PendingCN112127802AIncrease development costsShorten the life cycleDrilling rodsFluid removalIsolation valvePipe

The invention discloses an unlimited-level full-bore staged fracturing sand prevention pipe column. The pipe column comprises a suspension fracturing packer, a shaft isolation valve and a float shoe,wherein at least three layers of staged fracturing sand prevention double-stage mechanisms are arranged between the suspension fracturing packer and the shaft isolation valve; each staged fracturing sand prevention double-stage mechanism comprises an open hole fracturing packer, a fracturing suite, a production suite, an unpacking component and a double-stage screen pipe; the unpacking componentsare put to open the fracturing suites to achieve fracturing construction of all layers of the pipe column; and the unpacking components are put to open the production suites to achieve a double-layerscreen pipe full-bore production channel, and meanwhile the fracturing suites are closed to achieve the sand prevention effect. Accordingly, the problem that the number of staged fracturing layers ofan oil-gas well is limited by the inner diameter of the fracturing construction pipe column and the ball seat level difference is solved, and one-layer or unlimited-level segmentation is achieved; andmeanwhile, the sand prevention function after oil-gas well fracturing is achieved, the exploitation life cycle of the oil-gas well is prolonged, and the production cost is reduced.

Owner:天津凯雷油田技术有限公司

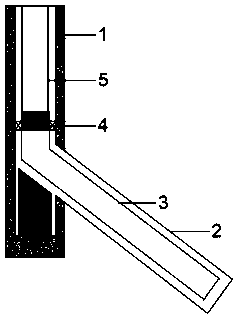

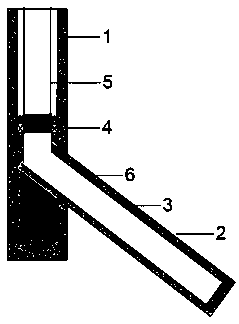

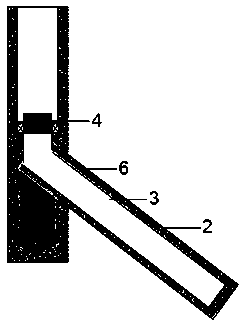

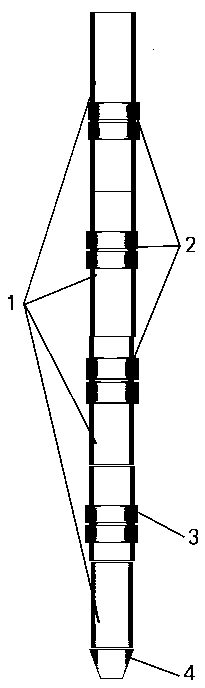

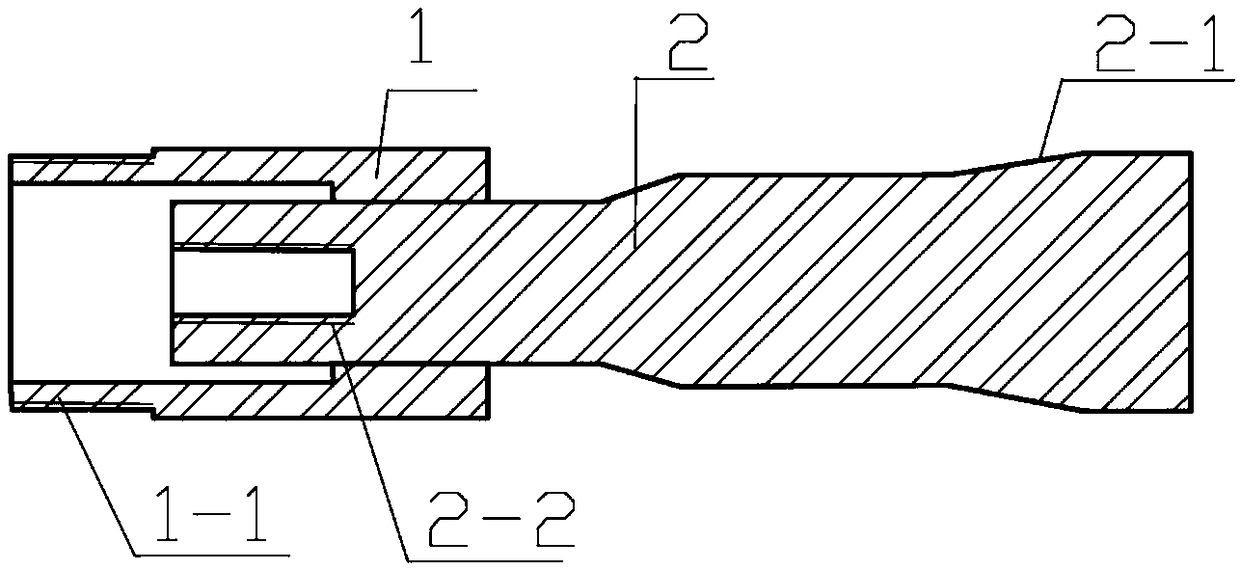

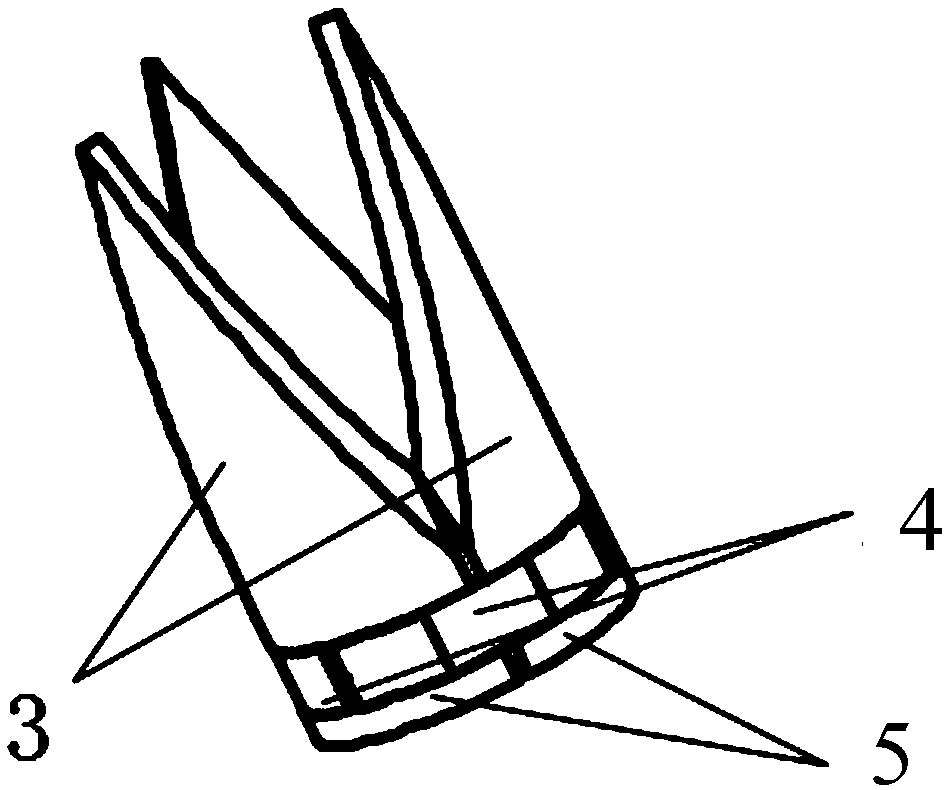

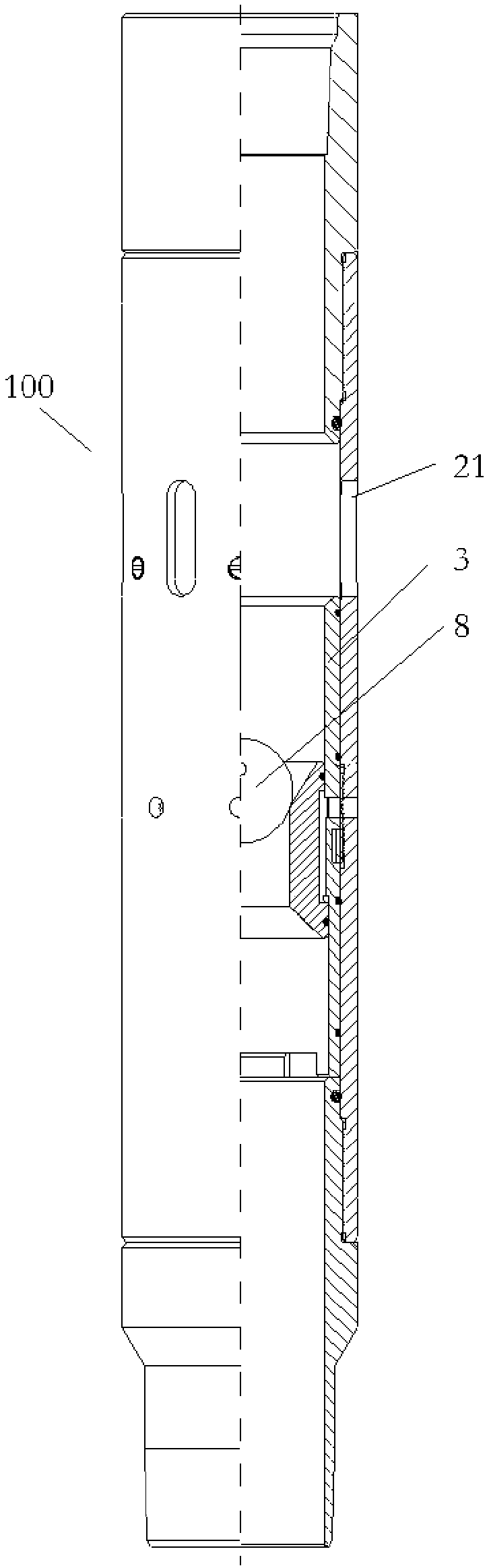

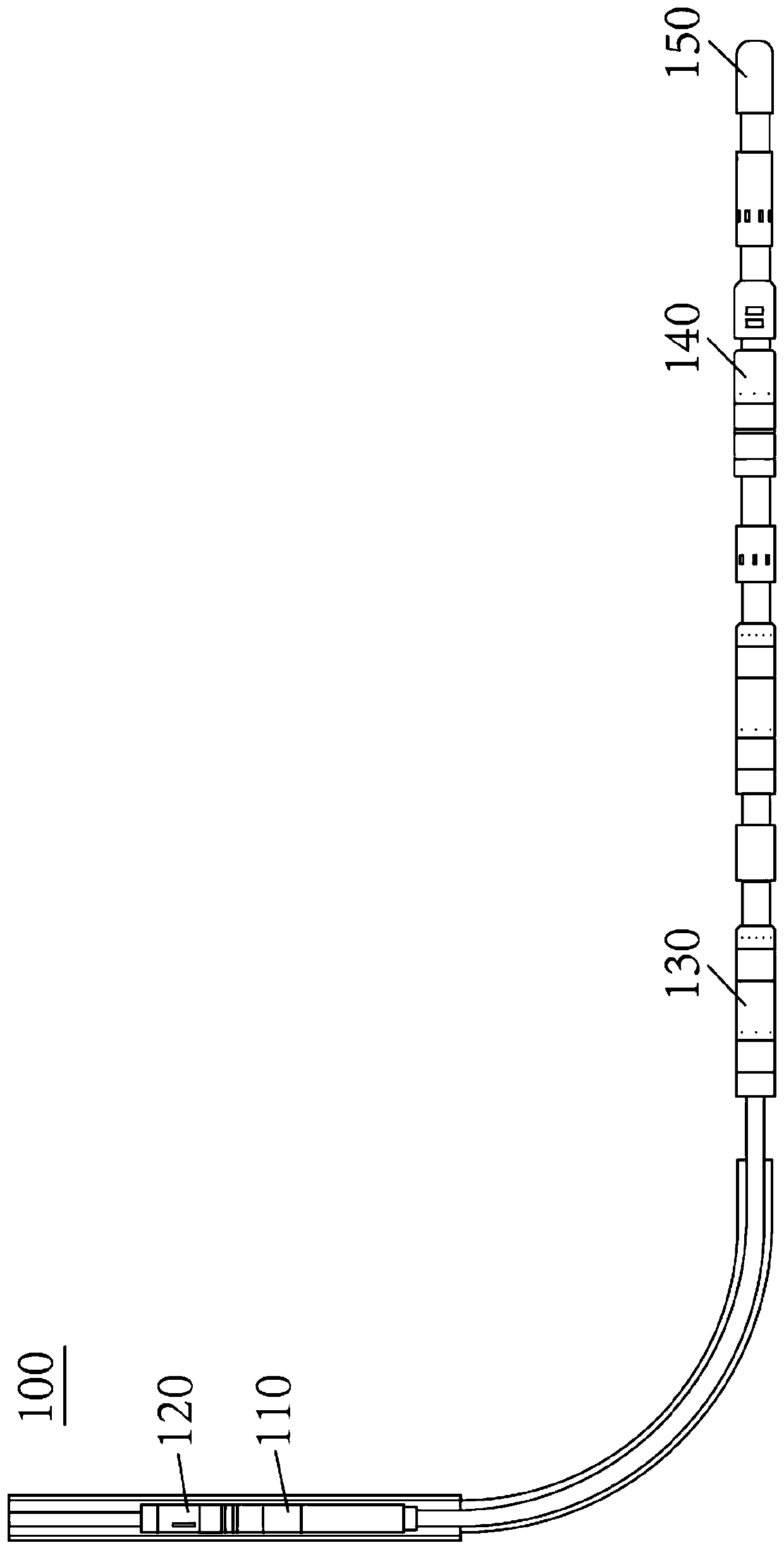

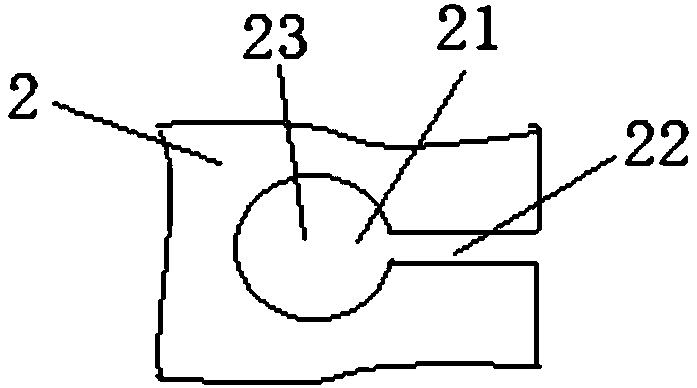

Casing string applying toe end sliding sleeve to full-drift-diameter sliding sleeve and using method thereof

PendingCN111425148AAvoid getting stuckFull boreDrilling rodsWell/borehole valve arrangementsStructural engineeringCasing string

The invention discloses a casing string applying a toe end sliding sleeve to full-drift-diameter sliding sleeves and a using method thereof. The casing string comprises multiple casing pipes (1), a sliding sleeve accessory, the multiple full-drift-diameter sliding sleeves (2) and the toe end sliding sleeve (3). According to the casing string applying the toe end sliding sleeve to the full-drift-diameter sliding sleeves and the using method thereof, the toe end sliding sleeve (3) is used for establishing a first-section fracturing channel, and when it comes to a complex structural well, the phenomenon that the well is stuck can be effectively avoided; an infinite fracturing method of the full-drift-diameter sliding sleeves (2) is used, and full drift diameter is achieved; and a soluble fracturing ball (8) with the drift diameter of more than 100 mm after being dissolved is used to adapt to the inner diameter of each casing pipe (1), so that smoothness of the casing string is ensured.

Owner:CHINA PETROLEUM & CHEM CORP +2

High-ductility small-diameter dissoluble bridge plug

InactiveCN112253044AFull boreFacilitate subsequent constructionSealing/packingAlloyUltimate tensile strength

The invention discloses a high-ductility small-diameter dissoluble bridge plug. The high-ductility small-diameter dissoluble bridge plug comprises a setting outer barrel, a connector, a central pipe,a releasing shear pin, a spacer ring, a starting shear pin, an upper slip, slip particles, an upper cone, an anti-rotation pin, a protection ring, a packer rubber assembly, a lower cone, a lower slipand a base. Except a packer rubber, the other body materials of the dissoluble bridge plug are made of high-elongation soluble metal magnesium-based alloy, the elongation of the soluble metal magnesium-based alloy is larger than 30%, the yield strength is not smaller than 280 MPa, the hardness is larger than 60 HB, and the dissolution rate in a KCl solution with the mass percent concentration of 3% at 93 DEG C reaches 70 mg / h.cm<2>. The inner surfaces of the upper cone and the lower cone are designed to be sawtooth-shaped, so that the roughness of the inner surfaces of the cones is increased,and axial locking of the dissoluble bridge plug after setting is guaranteed. The high-ductility small-diameter dissoluble bridge plug is used for plugging measures in the fracturing process, the bridge plug can be completely dissolved in a shaft after fracturing construction is completed, the full diameter of the shaft is achieved, and convenience is provided for follow-up construction.

Owner:CNPC BOHAI DRILLING ENG +1

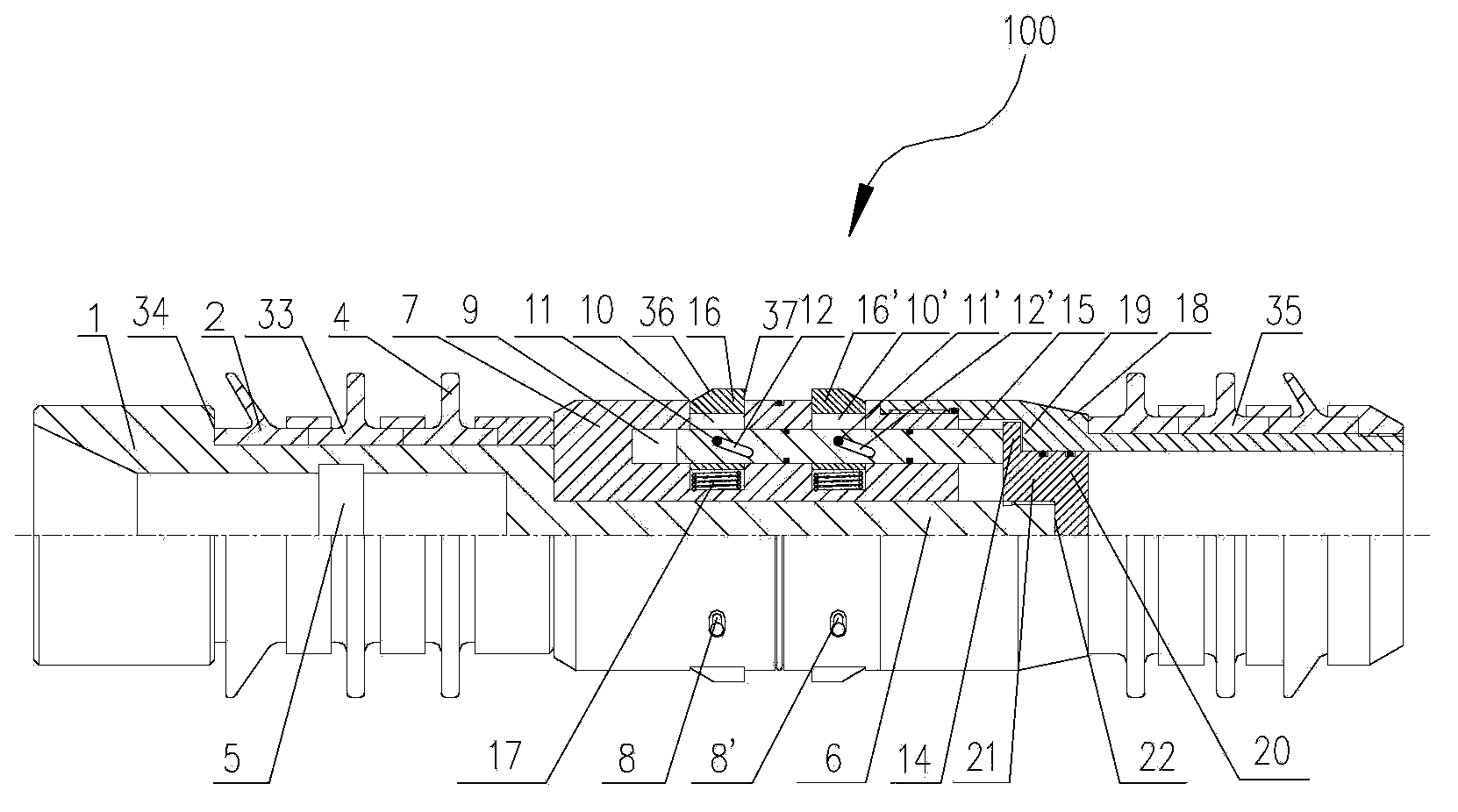

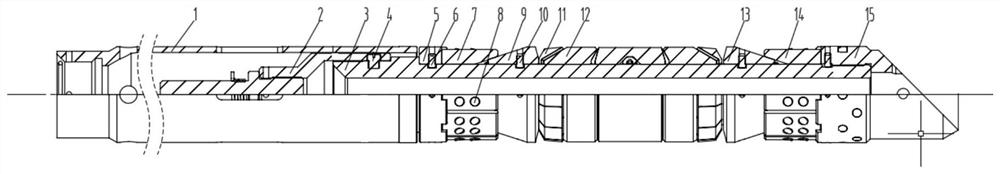

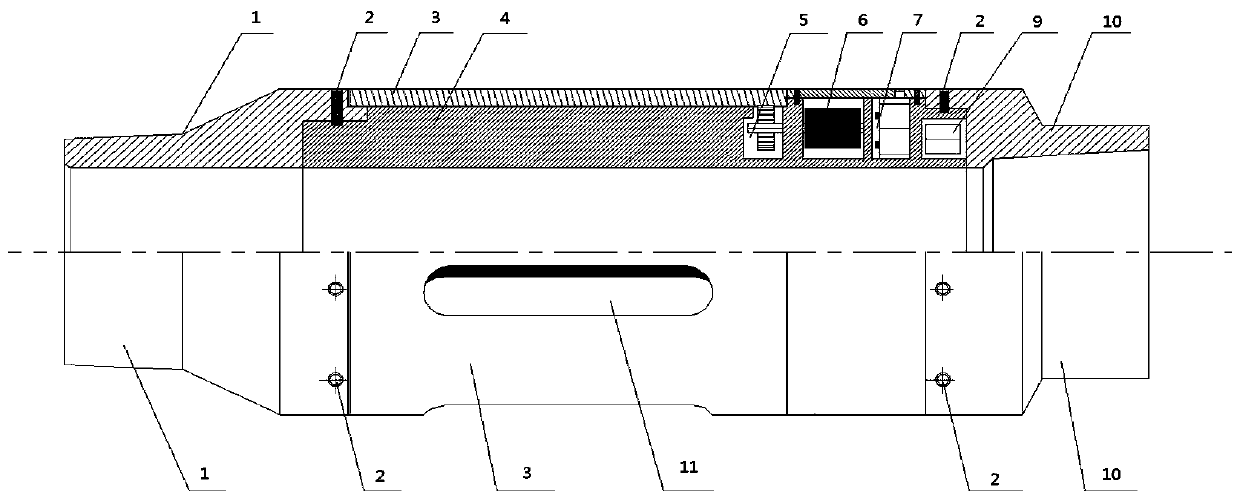

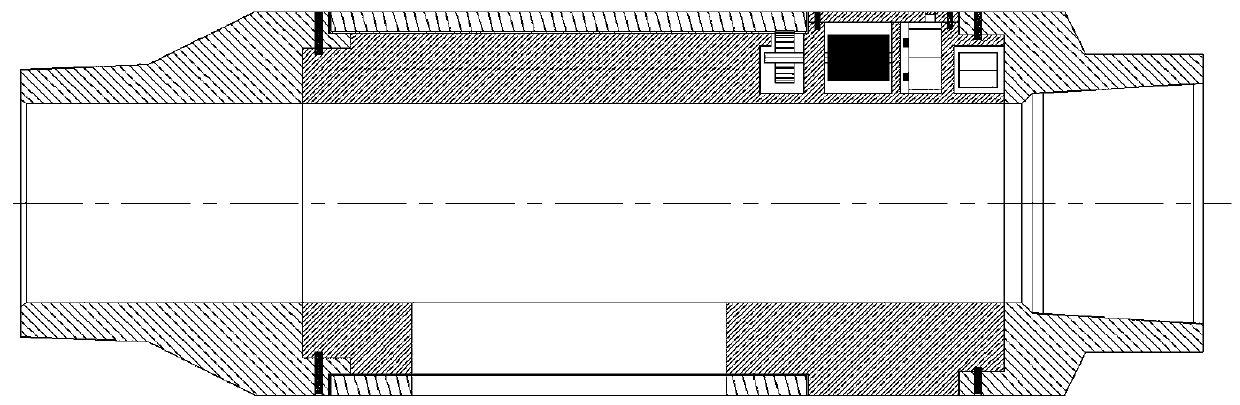

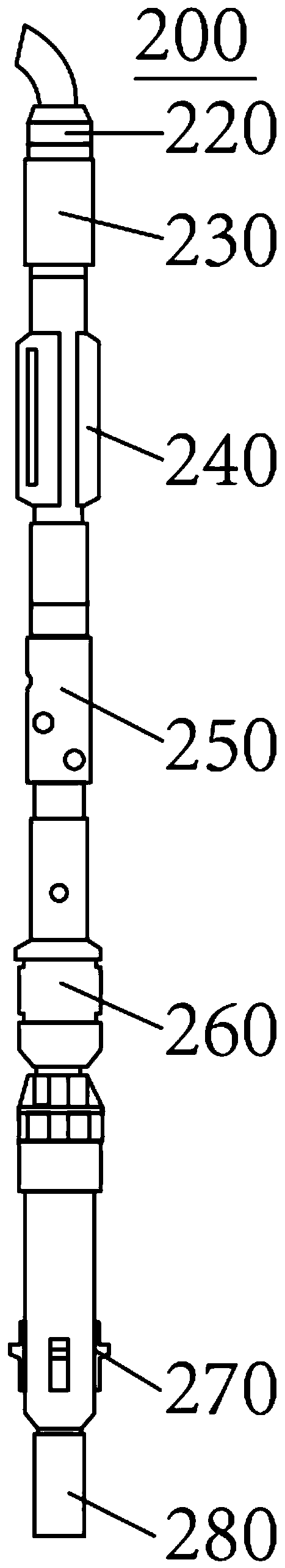

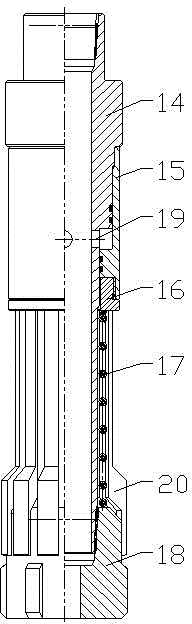

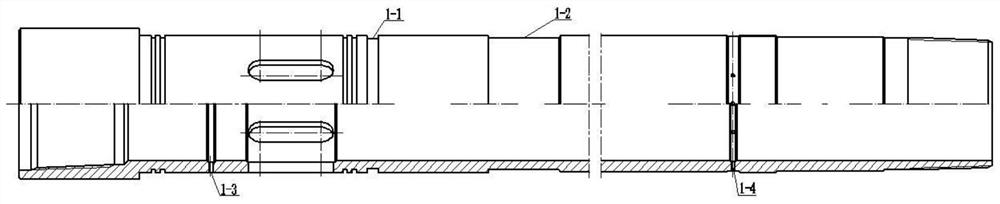

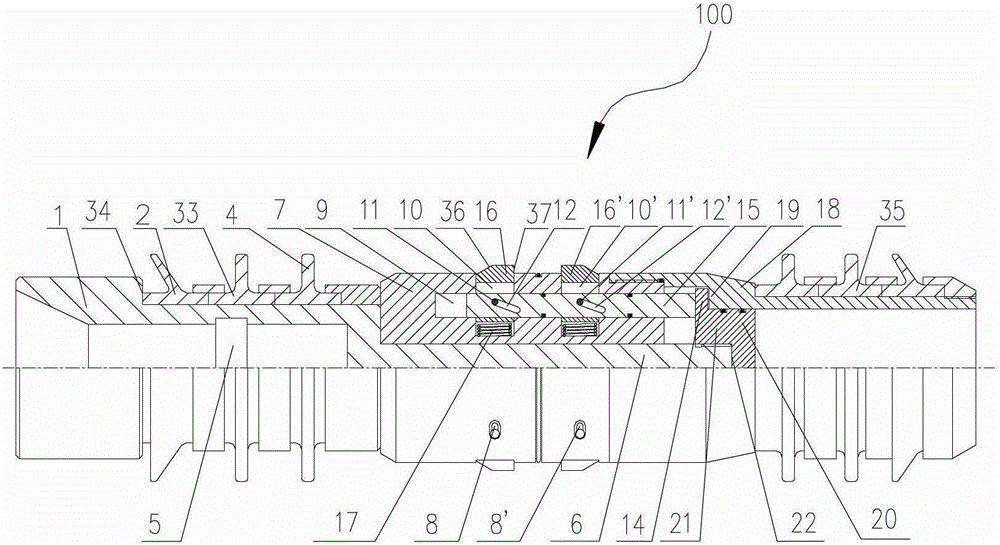

Downhole Infinite Stage CNC Fracturing Sleeve

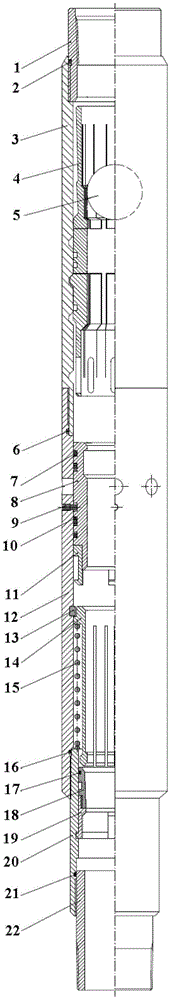

ActiveCN103806888BThe need to realize multi-level fracturing stimulationFull boreFluid removalWell/borehole valve arrangementsUltimate tensile strengthDigital control

The invention discloses a downhole infinite level digital control fracture sliding sleeve, which is designed for realizing the improvement of the digital control fracturing of separate layers of an oil-gas plumb shaft, and comprises a digital control fracture sliding sleeve, a digital control blocking device and an unblocking plug. The digital control fracture sliding sleeve comprises an upper connector, a connecting sleeve, a body and a lower connector, and an inner sliding sleeve provided with a position ID card is arranged in the connecting sleeve; the digital control blocking device comprises a gland, a main body sleeve and a bottom plug, and is internally provided with a pressure lever, a reducing piston, a sealing plate, a guide pipe and a control plate which are matched with one another for moving, and a lever mechanism on the control plate is connected with a valve on the bottom plug; the unblocking plug mainly comprises an end cover, a V-shaped seal and a mandril. By the downhole infinite level digital control fracture sliding sleeve, the requirements on the improvement of multi-layer fracture and selective exploration of an oil-gas field, the full bore of a downhole pipe string is realized, liquid discharge can be performed directly, the fracture sliding sleeve can be opened by continuous oil pipes or cables and other opening and closing tools, fracture transmitting pipelines can be reduced, and labor intensity and construction risk can be reduced.

Owner:PETROCHINA CO LTD

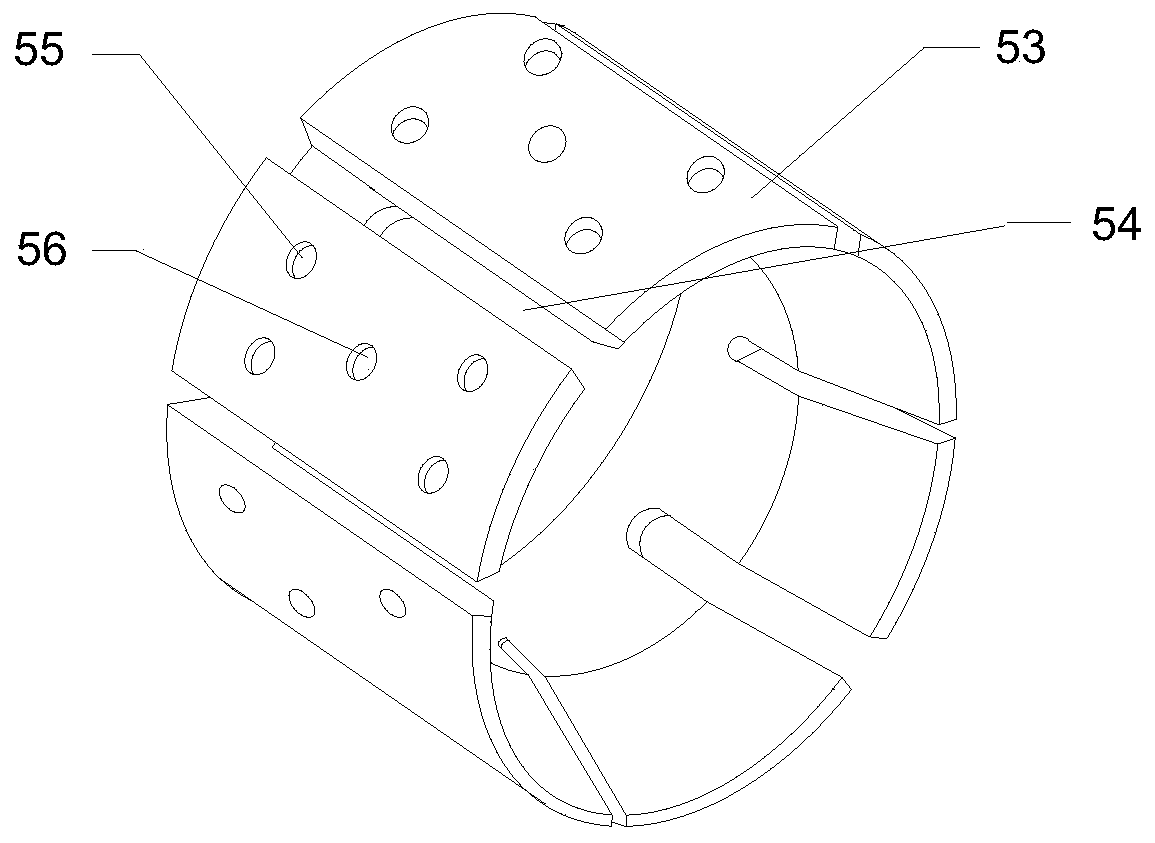

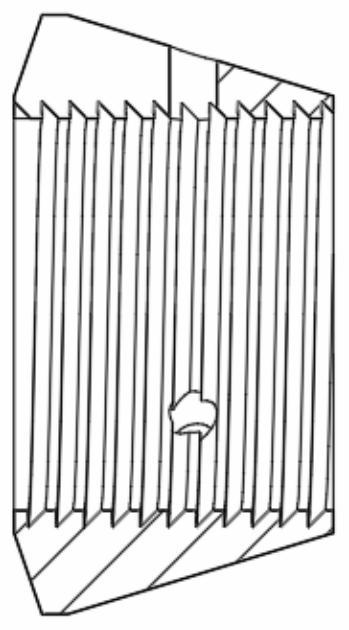

Umbrella-key laminated sealed seat full-diameter soluble fracturing sliding sleeve

ActiveCN108691518ASimple short circuit structureGuaranteed uptimeFluid removalWell/borehole valve arrangementsEngineeringMechanical engineering

The invention discloses an umbrella-key laminated sealed seat full-diameter soluble fracturing sliding sleeve comprising a seat sealing device, an umbrella-key laminated sealing seat, a plugging device and a sleeve short circuit. The seat sealing device is composed of a housing and an expending connecting rod; an upper part of the expanding connecting rod is placed inside the housing and the middle part is circumferentially in touch with the umbrella-key laminated sealing seat. the umbrella-key laminated sealing seat is composed of an umbrella-key laminated layer, an interlayer and a gasket layer and is assembled by a groove slide rail and a projecting slide block by connecting. When a gunpowder seat sealing tool is started, the extending connecting rod is lifted upward to have a relativedisplacement with the housing; the umbrella-key laminated sealing seat is guided by the groove slide chute to form the final umbrella-key laminated sealing seat. After the umbrella-key laminated sealing seat is formed, it is seat-sealed on the sleeve short circuit and then is lifted out of a well head by a cable. Finally, the plugging device and the umbrella-key laminated sealing seat are combinedto block the layer to be fractured, and the fracturing operation of the layer can be performed.

Owner:CNPC BOHAI DRILLING ENG +1

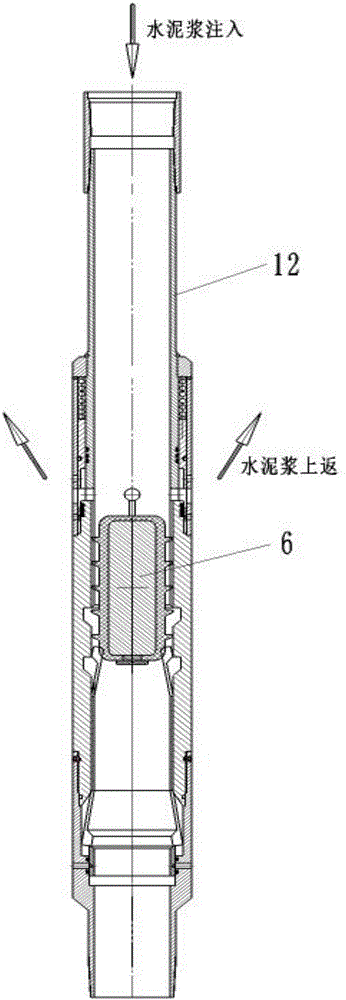

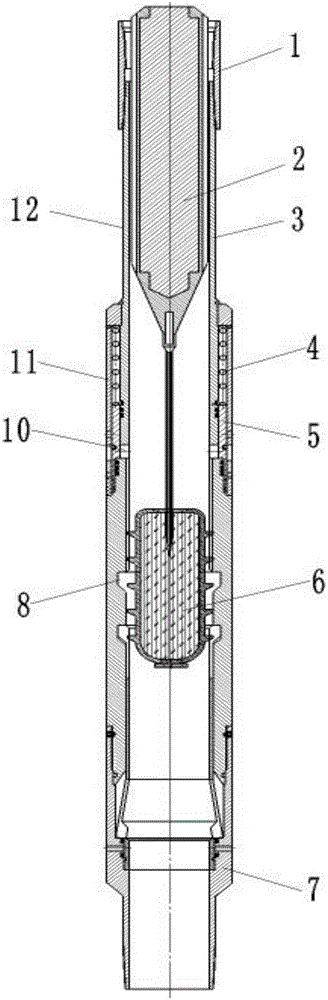

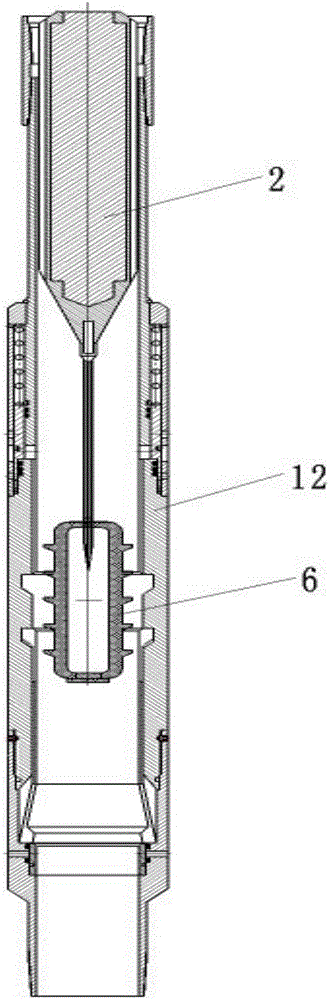

Drilling-free hierarchical cementing method and cementing device

ActiveCN106437608AReliable conditions to trigger inflationTo achieve the cementing effectSealing/packingWell cementingEngineering

The invention discloses a drilling-free hierarchical cementing method and a cementing device. The cementing device is composed of a full-bore pressure-difference hierarchical hoop, a rubber plug and a gravity hammer, the full-bore pressure-difference hierarchical hoop comprises a sleeve, an upper connecting hoop and a lower connecting hoop, the upper connecting hoop and the lower connecting hoop are connected at two ends of the sleeve, grouting holes and annular clamping grooves are formed in the inner wall of the sleeve from top to bottom respectively, a pressure difference sleeve sleeves positions of the grouting holes on the outer wall of the sleeve, a sealing sleeve capable of sliding up and down is arranged between the sleeve and the pressure difference sleeve, and the front end of the sealing sleeve seals and covers the grouting holes while the rear end of the same is in elastic contact with a spring. The rubber plug with a filler can expand along with changing of environment temperature; temperature of a well depth position at which the hierarchical hoop is located during well cementing operation is higher than 100 DEG C usually, so that a condition of triggering expansion of the rubber plug is more reliable, and well cementing effect of conventional well cementing rubber plugs is realized.

Owner:GUIZHOU GAOFENG GASOLINEEUM MACHINERY

Recyclable bidirectional anchoring sieving pipe hanger and recyclable bidirectional anchoring sieving pipe system

The invention provides a recyclable bidirectional anchoring sieving pipe hanger and a recyclable bidirectional anchoring sieving pipe system. The recyclable bidirectional anchoring sieving pipe hangercomprises a body, an upper taper sleeve, a lower taper sleeve, a slip assembly, an upper transmitting-loading assembly and a lower recovery sleeve assembly; the upper taper sleeve is connected to theexterior of the body in a sleeving mode; the lower taper sleeve is connected to the exterior of the body in a sleeving mode and located on the lower part of the upper taper sleeve; the slip assemblyis connected to the exterior of the body and connects the upper taper sleeve with the lower taper sleeve; the upper transmitting-loading assembly is connected to the upper end of the body in a sleeving mode and connected with the body through a setting shearing nail, and the lower end of the upper transmitting-loading assembly is connected with the upper taper sleeve and matched with a feed tool to realize setting of the hanger; and the lower recovery sleeve assembly is connected to the lower end of the body in a sleeving mode, connected with the lower taper sleeve and matched with a salvage tool to realize setting removal of the hanger. The whole length of the sieving pipe hanger is smaller, wellhead construction is convenient, the bidirectional anchoring ability is achieved after setting, full drift diameter of a tail pipe can be realized after releasing, recycling and reusing of a sieving pipe can further be achieved, and the cost is saved.

Owner:CHINA PETROLEUM & CHEM CORP +2

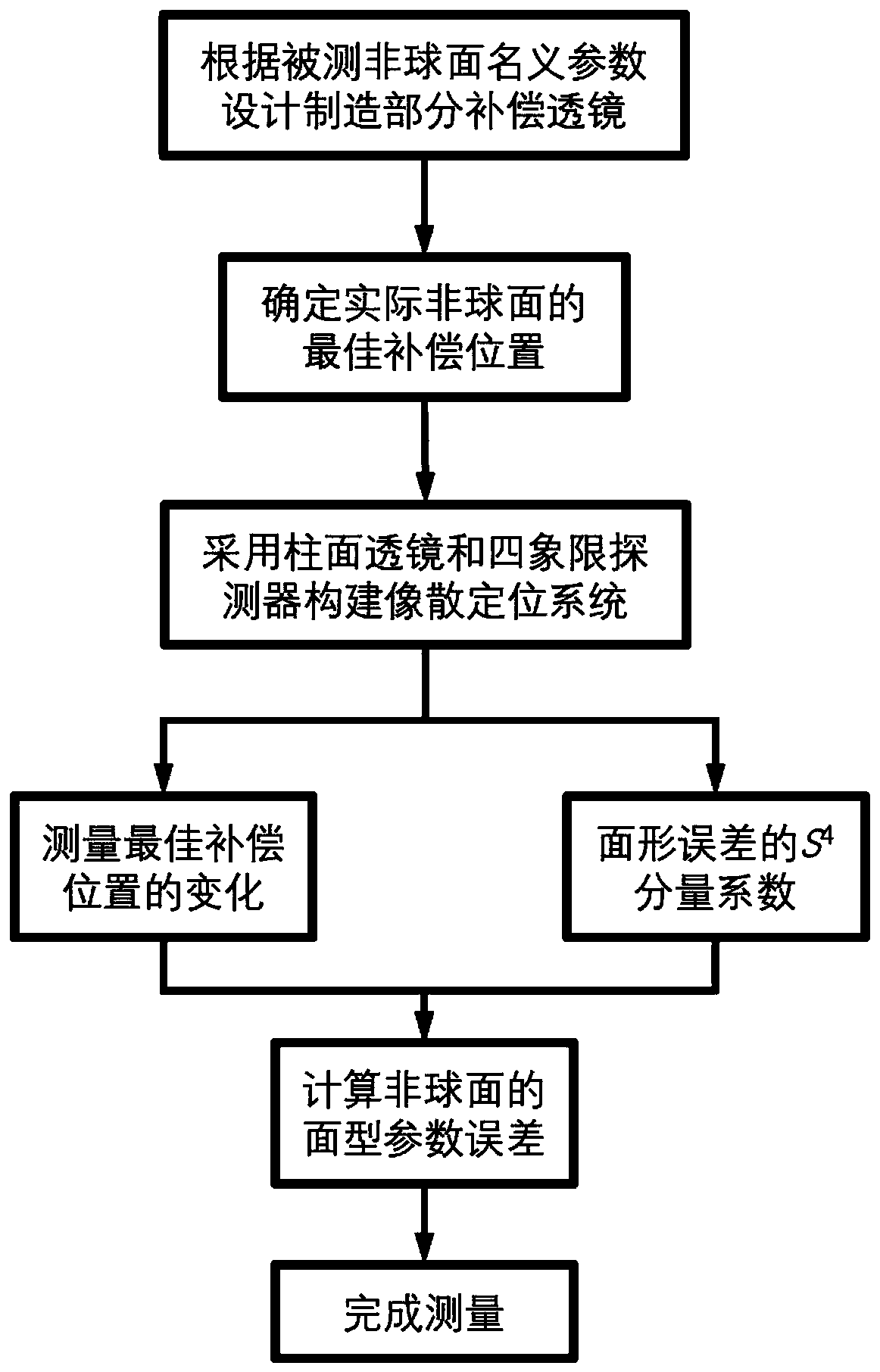

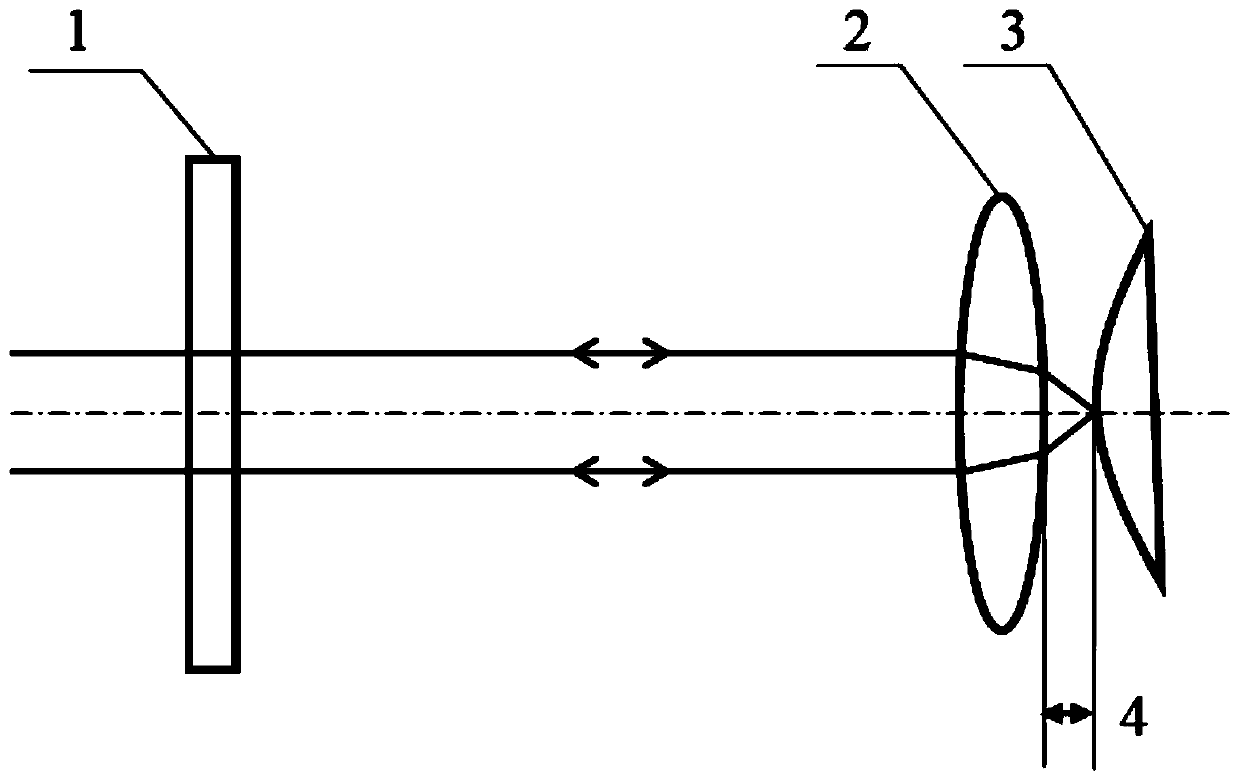

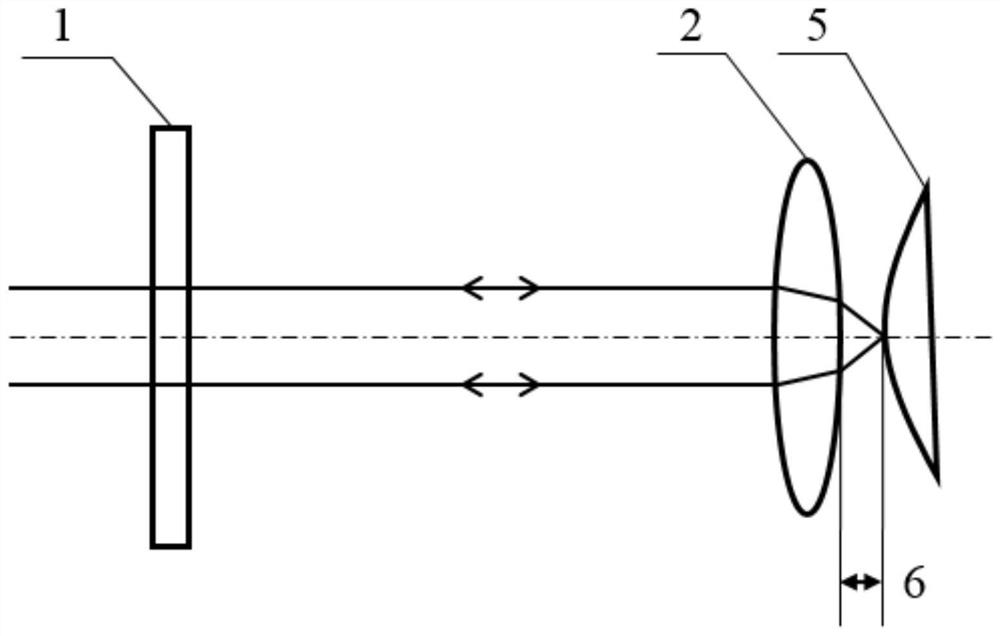

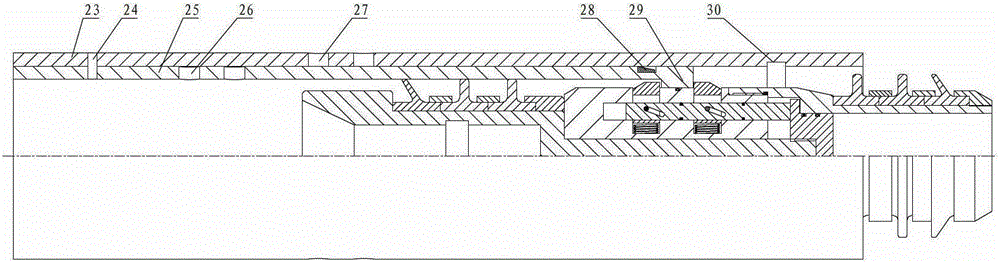

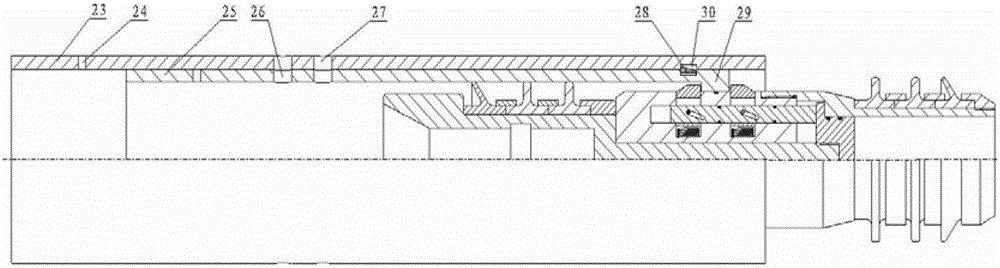

Aspheric parameter error interference measurement method and system combined with astigmatism method positioning

ActiveCN110686617AAvoid distance measurementsSimple structureUsing optical meansMechanical engineeringMeasurement precision

The invention discloses an aspheric parameter error interference measurement method and system based on astigmatism method positioning. An aspheric parameter error interference measurement system is established by combining an astigmatism positioning system, so a complex laser differential confocal system does not need to be built, the influence of the adjustment error of the laser differential confocal system on the measurement precision is avoided, and the measurement precision of the surface type parameter error of the aspheric surface is further improved; moreover, the non-contact, full-aperture and high-precision measurement can be achieved, and the system has the advantages of simple structure and convenient adjustment.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Full-diameter switchable slide sleeve for fracturing and using method thereof

PendingCN110130855ARealize switchableAffectFluid removalWell/borehole valve arrangementsEngineeringHigh pressure

The invention specifically relates to a full-diameter switchable slide sleeve for fracturing and a using method thereof. The full-diameter switchable slide sleeve for fracturing includes an upper connector, a lower connector, a slide sleeve body, and an outer slide sleeve, wherein the upper connector and the lower connector are connected to the upper end and the lower end of the slide sleeve body;and the outer slide sleeve is located on the outer side of the slide sleeve body and rotatably connected with the slide sleeve body. The full-diameter switchable slide sleeve for fracturing is characterized in that ring-shaped grooves are formed in the slide groove body and the outer slide sleeve correspondingly; a driven gear is arranged on the outer slide sleeve, and a driving gear for drivingthe driven gear is arranged on the slide sleeve body; and a driving device for driving the driving gear to rotate is further included. According to the full-diameter switchable slide sleeve for fracturing and the using method thereof, a moving part sleeves the outer side of the slide sleeve, during fracturing, a high-pressure fluid does not impact the moving part of the slide sleeve.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

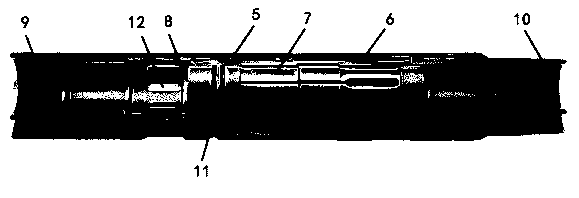

Large-drift-diameter treatment-free downhole high-pressure temporary plugging tool and method

The invention belongs to the technical field of oil and gas field downhole technical operation tools, and particularly relates to a large-drift-diameter treatment-free downhole high-pressure temporaryplugging tool and method. The large-drift-diameter treatment-free downhole high-pressure temporary plugging tool is formed by organically combining a releasing mechanism, a sealing and clamping mechanism, a temporary plug, a supporting seat and a fixing piece. According to the large-drift-diameter treatment-free downhole high-pressure temporary plugging tool and method, through the penetrating type releasing structure, simpleness and reliability are achieved, the overall size of the tool is small, and the characteristic that the releasing load is adjustable due to the fact that the size of the releasing structure is changed is fully utilized; the main load is borne through the bottom supporting seat, stress of a center pipe is avoided, and the material performance limitation is broken through; and the center pipe has the large drift diameter with the pipe diameter being larger than or equal to 50mm and can be consistent with the inner diameter of a production oil pipe, later-period liquid discharging and oil pipe passing operation are smoothly conducted, and the construction safety is guaranteed. A cone, a protective umbrella, a protective ring and a rubber cylinder in the large-drift-diameter treatment-free downhole high-pressure temporary plugging tool all adopt self-releasing materials, failure can be automatically released after construction is finished, and the full driftdiameter of a shaft can be achieved without special treatment subsequently.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Fracturing sliding sleeve and fracturing pipe string including fracturing sliding sleeve

The invention provides a fracturing sliding sleeve and a fracturing pipe string including the fracturing sliding sleeve. The fracturing sliding sleeve includes a cylindrical casing, an inner sleeve which is arranged in an inner cavity of the casing and is used for sealing a circulation hole, a ball seat arranged in an inner cavity of the inner sleeve, and a ball matched with the ball seat, whereinthe circulation hole communicating with the inside and the outer side is arranged on a wall of the casing, after the thrown ball is combined with the ball seat, the pressure fluid is pumped, under the action of the hydraulic force, the ball seat and the inner sleeve move downwards together to expose the circulation hole, the ball seat finishes contacting with the liquid, and chemical reaction occurs. The fracturing sliding sleeve is advantaged in that the full diameter of the fracturing pipe string can be conveniently realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Intelligent water controlling pup joint

Owner:JILIN GUOTAI GASOLINEEUM DEV

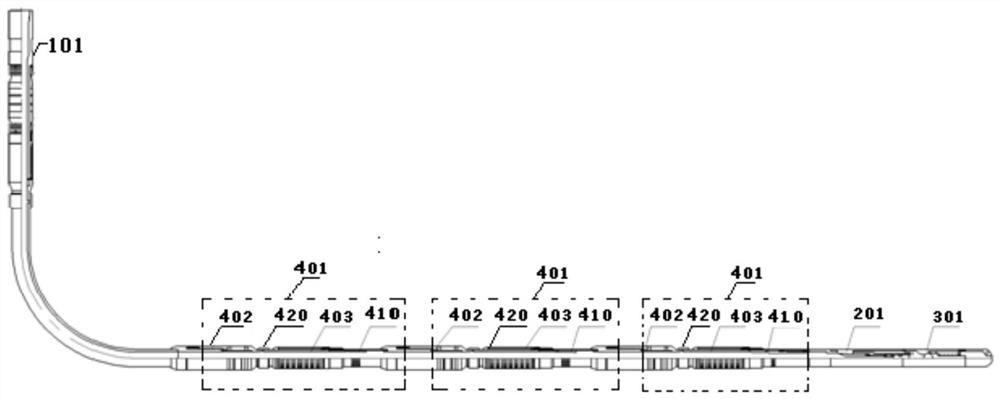

Whole path and infinite stage segmented fracturing tool and use method thereof

PendingCN111236909AEasy to enterSmall outer diameterDrilling rodsFluid removalCoiled tubingStructural engineering

The invention discloses a whole path and infinite stage segmented fracturing tool and a use method thereof. The whole path and infinite stage segmented fracturing tool comprises a casing pipe, a casing pipe outer open hole packer component and a bottom packer component, wherein the casing pipe is provided with a plurality of liquid outlets; the casing pipe outer open hole packer component comprises a plurality of pipe outer packers and a bottom circulation assembly; the plurality of pipe outer packers are sheathed out of the casing pipe; in addition, the upper part and the lower part of each liquid outlet are independently provided with the pipe outer packer; the bottom circulation assembly is installed on the bottom of the casing pipe; the bottom packer component is sheathed in the casingpipe and comprises a continuous oil pipe, a perforation spray gun and the bottom packer, wherein the perforation spray gun is installed on the continuous oil pipe and communicates with the continuousoil pipe; and the bottom packer is fixedly installed on the bottom of the continuous oil pipe. According to the whole path and infinite stage segmented fracturing tool disclosed by the invention, theproblem of an unstable well wall of open hole completion is solved, meanwhile, an inner whole path of the casing pipe is realized, the minimum inner diameter of a shaft after fracturing is the innerdiameter of the casing pipe, and an enough space is provided for operations, including later-period production, well repairing and the like.

Owner:PETRO KING ENERGY TECH HUIZHOU CO LTD

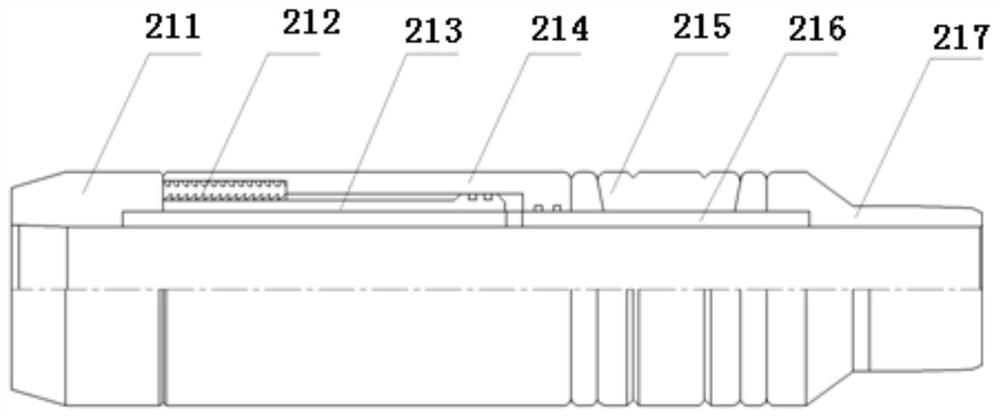

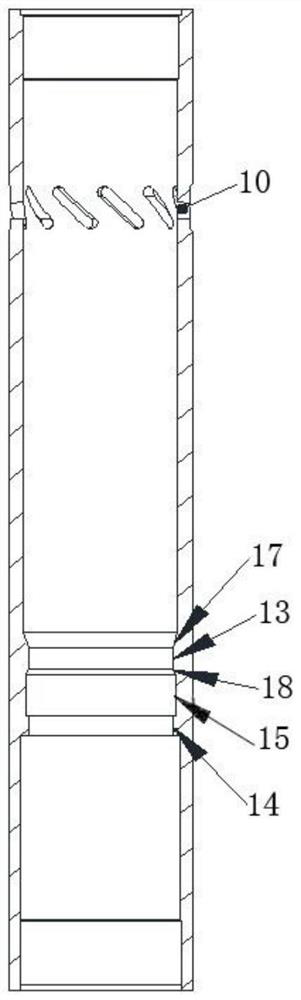

Sliding sleeve structure for permanent completion and application method thereof

ActiveCN104481454AOpen smoothlyTurn on influenceFluid removalWell/borehole valve arrangementsLocking mechanismSelf locking

The invention discloses a sliding sleeve structure for permanent completion and an application method thereof. An upper connector and a lower connector are fixedly connected to upper and lower ends of a body, respectively. The body is provided with a jet channel. A movable sliding sleeve disposed within the body closes the jet channel and is connected to the body through a pin. A claw hook is arranged at the upper end of the movable sliding sleeve. The inner wall of the movable sliding sleeve is provided with a closing groove matching with a closing tool. An easy-drilling ball seat is fixed to the lower portion of the movable sliding sleeve. An inner cavity of the body is provided with a first resistance groove and a second resistance groove matching with the claw hook; the first resistance groove and the second resistance groove are provided in the upper and lower portions of the jet channel, respectively. A self-locking mechanism is used for locking the movable sliding sleeve and the body when a sectional optimizing sliding sleeve is open. The sliding sleeve structure has the advantages that a string sliding sleeve for permanent completion can be opened smoothly, reliable opening of the sliding sleeve and normal production of oil and gas are guaranteed, and the sliding sleeve can be selectively closed to close an aquifer and a waste layer according to late specific conditions of a reservoir.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Unlimited-grade well cementation sliding sleeve for preventing cement solidification and assembling and operating method thereof

ActiveCN112780227AAchieve fracturingEasy to assembleFluid removalWell/borehole valve arrangementsWell cementingStructural engineering

The invention discloses an unlimited-grade well cementation sliding sleeve for preventing cement solidification and an assembling and operating method thereof. The sliding sleeve comprises a central pipe, an upper positioning ring, a lower positioning ring, a piston sleeve and an outer sleeve. The sliding sleeve and a casing pipe are put down together, each section corresponds to one well cementation sliding sleeve, limitation of the number of layers is avoided, and multi-section fracturing can be achieved through one-time pipe column; a locking mechanism is simple and convenient to assemble, once the well cementation sliding sleeve is opened, a locking ring is limited by a straight step and cannot continue to move, and therefore the sliding sleeve is prevented from being closed by mistake; after fracturing construction is completed, the drift diameter in a well is the same as that of the casing pipe, hole shrinkage is avoided, full drift diameter is achieved, and secondary fracturing can be conducted; a certain inclination exists between an inclined long narrow seam on the outermost side and a put-down track, and therefore the risk that solid grease is scraped out of the wall of an open hole well can be reduced; and the contact area between cement and the outer side of the piston sleeve is small, and solidification is not likely to be firm. The piston sleeve for opening the sliding sleeve is not located on the inner side of the central pipe, and the sliding sleeve is prevented from being opened by mistake when the pipe column is put down in the sliding sleeve.

Owner:CNOOC ENERGY TECH & SERVICES

Fracturing short section and fracturing pipe string including fracturing short section

The invention provides a fracturing short section and a fracturing pipe string including the fracturing short section. The fracturing short section includes a cylindrical body, an inner sliding sleevewhich is arranged in an inner cavity of the body and is used for sealing a circulation hole, a ball seat arranged in an inner cavity of the inner sliding sleeve, and a ball matched with the ball seat, wherein the circulation hole communicating with the inside and the outside is disposed on a wall of the body, under the action of the first hydraulic force, the ball seat moves downwards relative tothe inner sliding sleeve, under the action of the second hydraulic force, the inner sliding sleeve moves downwards relative to the body, and the ball seat is constructed to be soluble to move away from the inner sliding sleeve after the inner sliding sleeve moves downwards. The fracturing short section is advantaged in that the full diameter of the fracturing pipe string can be conveniently realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

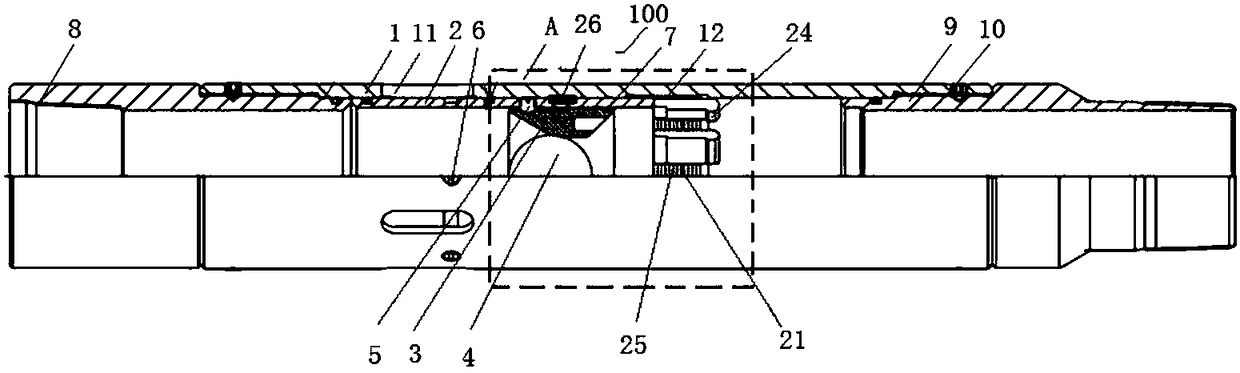

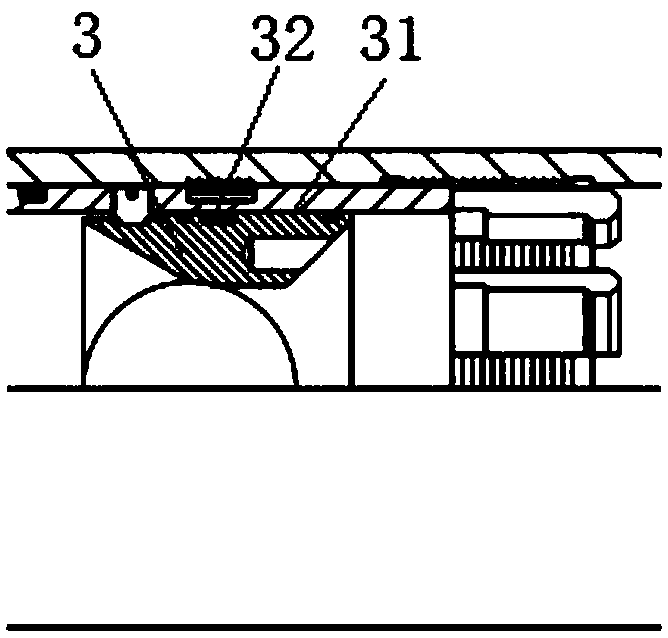

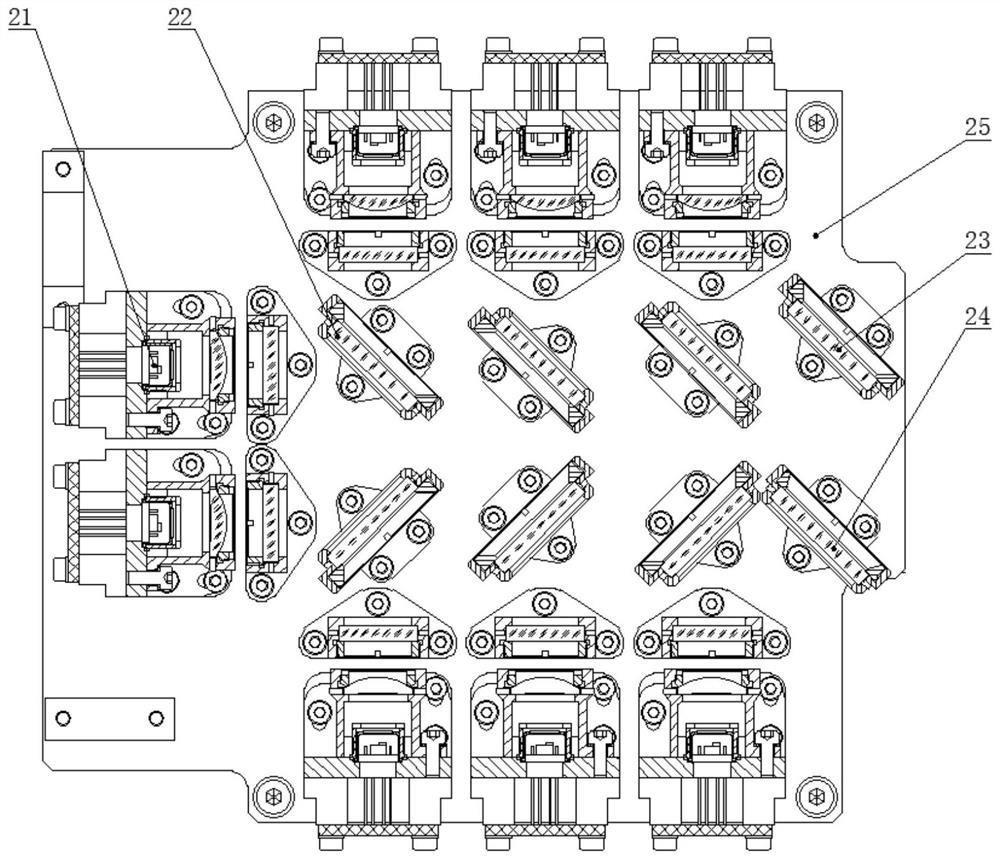

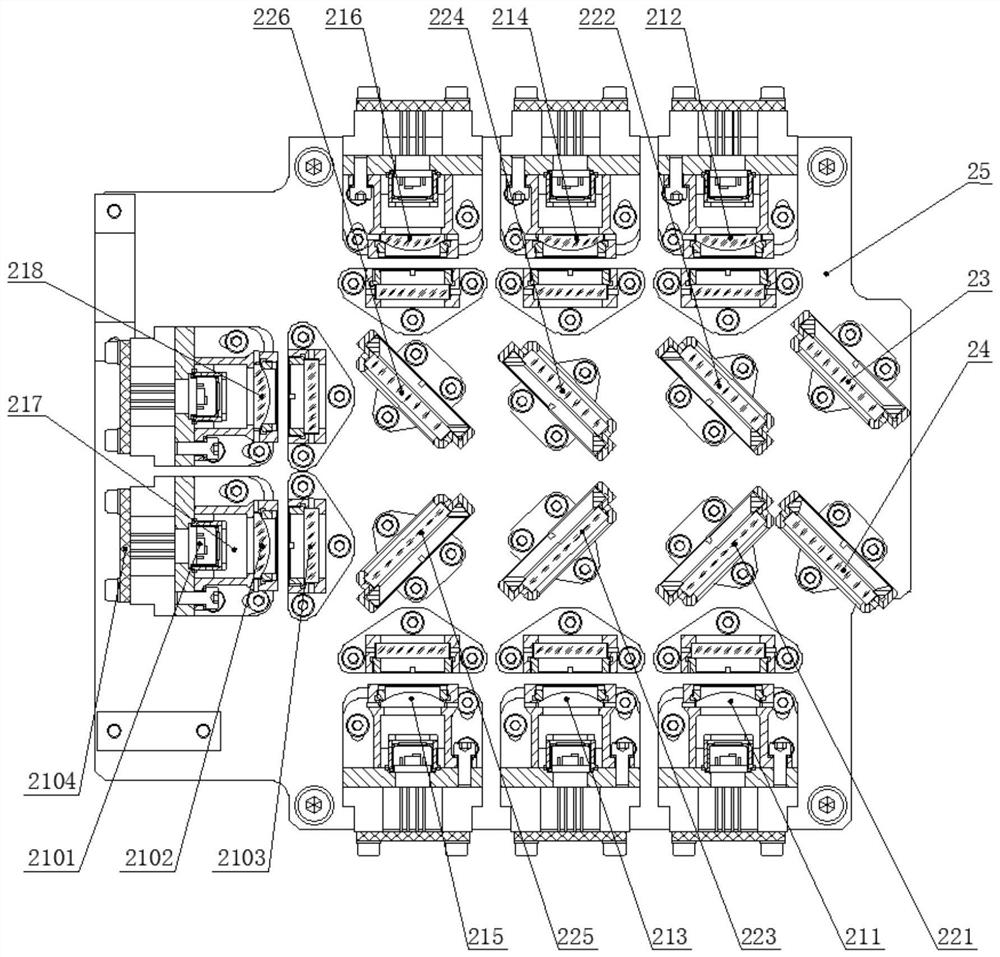

Chute counting type infinite-order full-bore well completion fracturing device

PendingCN114876408AFracturing RealizedSame structureFluid removalWell/borehole valve arrangementsEngineeringStructural engineering

The invention provides a chute counting type infinite-order full-bore well completion fracturing device which comprises a fracturing sliding sleeve and a soluble information ball, the fracturing sliding sleeve comprises an upper connector, a lower connector, an outer sleeve, a fixed sleeve, an annular piston and a counting core cylinder, and the annular piston seals the outer sleeve and inner and outer fracturing holes in the upper connector; the counting core cylinder is in clearance fit with the inner wall of the outer sleeve, a variable-diameter limiting ball seat and a rotary counting moving mechanism are arranged on the counting core cylinder, a limiting sleeve is arranged on the periphery of the counting core cylinder at the upper end of a limiting boss and corresponds to the position above the variable-diameter limiting ball seat, and a soluble information ball is matched with the variable-diameter limiting ball seat. According to the invention, a full-bore infinite-stage sliding sleeve is realized, a rotary sliding chute type counting mode is adopted, the structure is compact, the tool is simple and short, the counting quantity is easy to expand, the ball throwing structure is simple, the staged fracturing process requirements of an ultra-deep and ultra-long horizontal section well can be met, and the working efficiency is improved. Sliding sleeve opening faults are reduced, the fracturing efficiency is improved, and the construction cost is reduced.

Owner:武汉友智服能源科技有限公司

Fracturing sliding sleeve and fracturing pipe string including fracturing sliding sleeve

The invention provides a fracturing sliding sleeve and a fracturing pipe string including the fracturing sliding sleeve. The fracturing sliding sleeve includes a cylindrical casing, an inner sleeve which is arranged in an inner cavity of the casing and is used for sealing a circulation hole, a ball seat arranged in an inner cavity of the inner sleeve, and a ball matched with the ball seat, whereinthe circulation hole communicating with the inside and the outer side is arranged on a wall of the casing, after the thrown ball is combined with the ball seat, pumping pressure is performed, under the action of the hydraulic force, the ball seat and the inner sleeve move downwards together to expose the circulation hole, the ball seat finishes contacting with the liquid, and chemical reaction occurs. The fracturing sliding sleeve is advantaged in that the full diameter of the fracturing pipe string can be conveniently realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Grating spectrometer on-board spectrum calibration and instrument linear function monitoring device

PendingCN111623872ASimple structureHigh precisionRadiation pyrometrySpectrum investigationOptical spectrometerOptical path

The invention discloses a grating spectrometer on-board spectrum calibration and instrument linear function monitoring device. The device comprises a main force bearing frame, a laser beam combining system, a light uniformizing system and a collimation system. The laser beam combining system comprises a calibration light source unit combination, a color separation sheet combination, a reflector, abeam splitter and a supporting vertical plate. The light uniformizing system comprises an integrating sphere and a diaphragm; the collimation system comprises a reflecting mirror I, a reflecting mirror II and an optical filter; different calibration wavelength light sources emitted by the calibration light source unit combination are subjected to light path beam combination through the color separation sheet combination, the reflector and the beam splitter to obtain a combined light path, and finally, the combined light path irradiates into the light uniformizing system; the integrating sphere carries out light uniformizing processing on the combined light path and then, the combined light path enters the collimation system through the diaphragm; and the optical filter attenuates the light intensity of the combined light path after the light uniformizing treatment to obtain attenuated light, and the attenuated light is emitted out after being collimated by the reflecting mirror I andthe reflecting mirror II in sequence. According to the invention, on-board spectrum calibration and instrument linear function monitoring of the grating spectrometer are realized.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

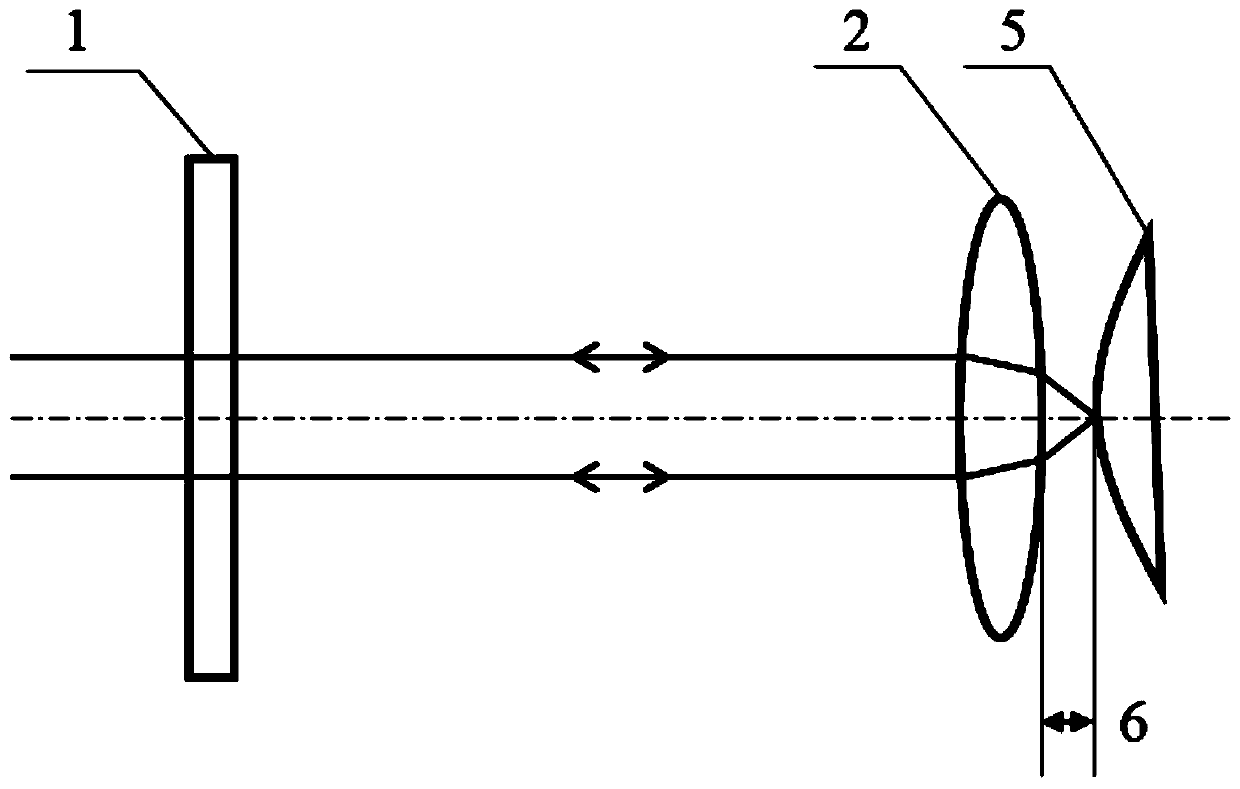

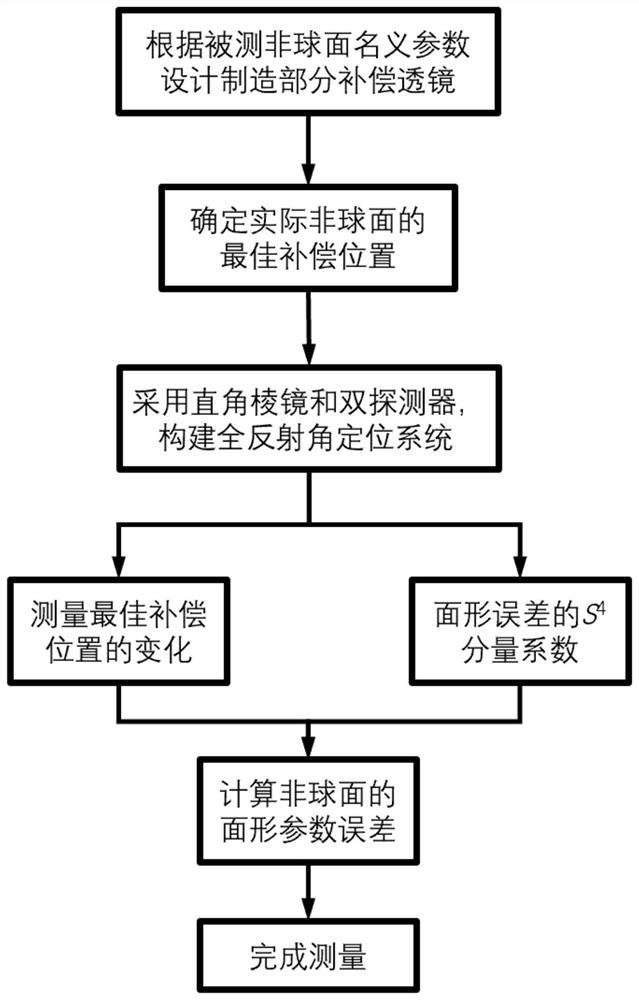

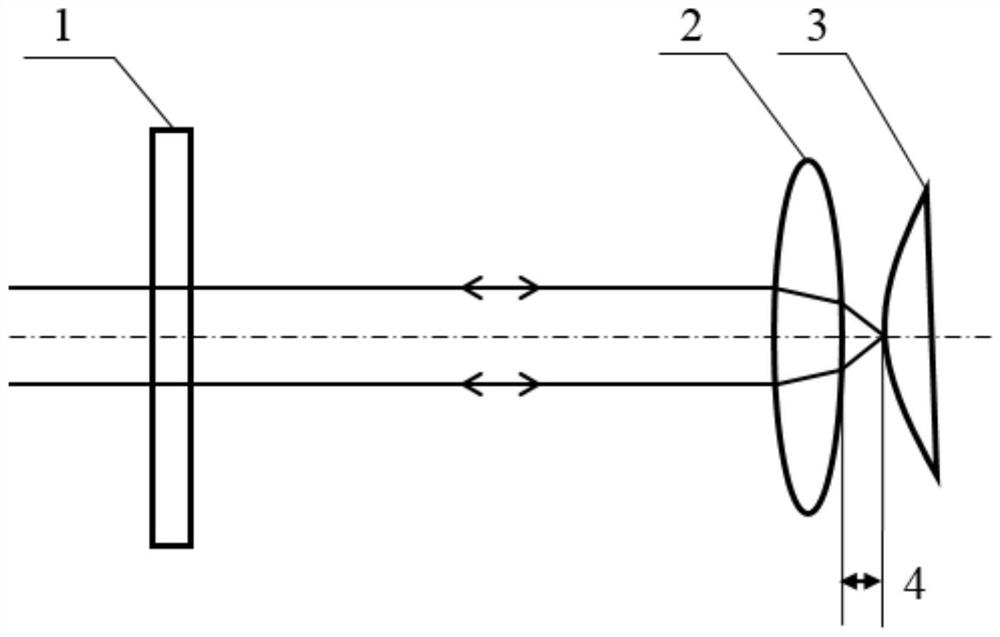

Aspherical surface parameter error interferometric method and system combined with total reflection angle positioning

ActiveCN110686618BAvoid distance measurementsSimple structureUsing optical meansOphthalmologyMeasurement precision

The invention discloses an aspheric parameter error interference measurement method and system combined with total reflection angle positioning. An aspheric parameter error interference measurement system is established by combining a total reflection angle positioning system, so a complex laser differential confocal system does not need to be built, the influence of the adjustment error of the laser differential confocal system on the measurement precision is avoided, and the measurement precision of the surface type parameter error of the aspheric surface is further improved; moreover, the non-contact, full-aperture and high-precision measurement can be achieved, and the system has the advantages of simple structure and convenient adjustment.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Slide switch device

ActiveCN103775047BFull boreUnlimited number of fracturing stagesFluid removalEngineeringMechanical engineering

The invention relates to a sliding sleeve opening and closing device comprising a stepped-shaft-shaped cylinder body and a locking block assembly installed at a first end of the body. A cylindrical supporting sleeve is arranged at the downstream of a shell, and an end cover is arranged between the supporting sleeve and the body. According to the sliding sleeve opening and closing device, the opening series of a sliding sleeve is not limited, flow-back is convenient, and working performance is reliable.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com