Casing string applying toe end sliding sleeve to full-drift-diameter sliding sleeve and using method thereof

A full-bore, sliding sleeve technology, applied in the direction of casing, drill pipe, earthwork drilling and production, etc., can solve the problems of complex trajectory in the horizontal section, self-locking pumping, and stuck coiled tubing for pumping bridge plugs, etc., to achieve The effect of avoiding the phenomenon of being stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will be described first with reference to the accompanying drawings.

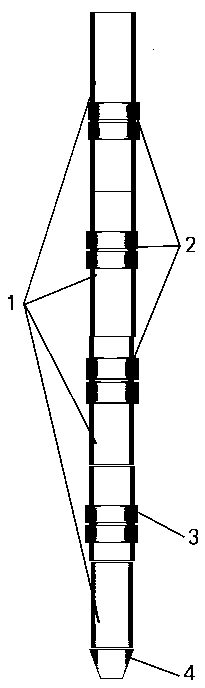

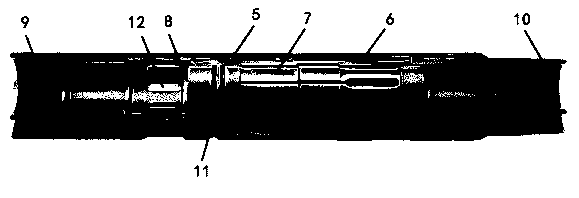

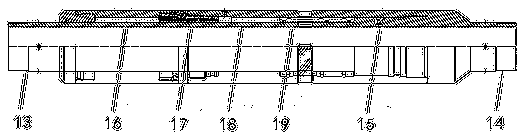

[0035] Such as figure 1 As shown, a casing string using a toe-end sliding sleeve to a full-bore sliding sleeve includes multiple casings 1, sliding sleeve accessories, multi-stage full-bore sliding sleeves 2 and toe-end sliding sleeves 3, wherein: The sliding sleeve accessories include a chuck 7 and a soluble fracturing ball 8 placed inside the upper end of the chuck 7. When fracturing, the fracturing device is pumped into the interior of the multi-stage full-bore sliding sleeve 2; the described Two sets of multi-stage full-bore sliding sleeves are respectively arranged on multiple casings 1 and connected to multiple casings 1 as the second stage, third stage... Nth stage fracturing sliding sleeve; the toe The end sliding slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com