Chute counting type infinite-order full-bore well completion fracturing device

A counting, infinite-level technology, applied to wellbore/well valve devices, wellbore/well components, production fluids, etc., can solve the problem of limited number of fracturing stages, large surface pressure fluctuations, and increased testing blindness Misjudgment and rework of the operation of the switch well, to reduce the difficulty of manufacturing and downhole, and prevent the failure of opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] For a better understanding of the present invention, the present invention will be further described below with reference to the accompanying drawings and embodiments.

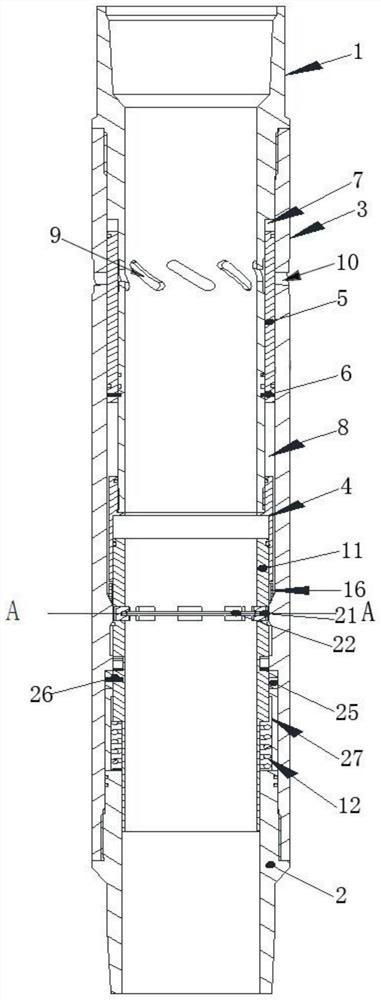

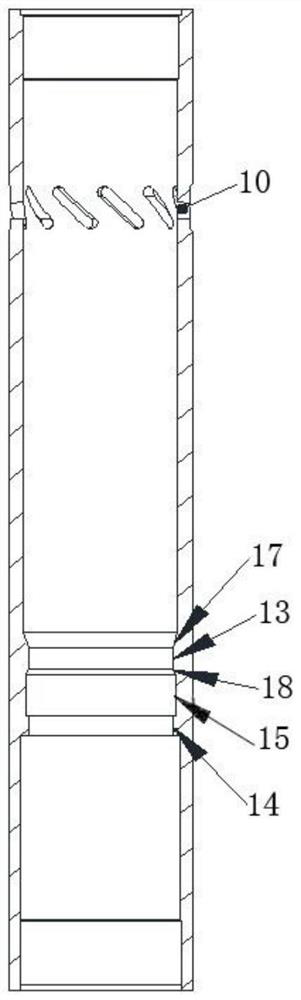

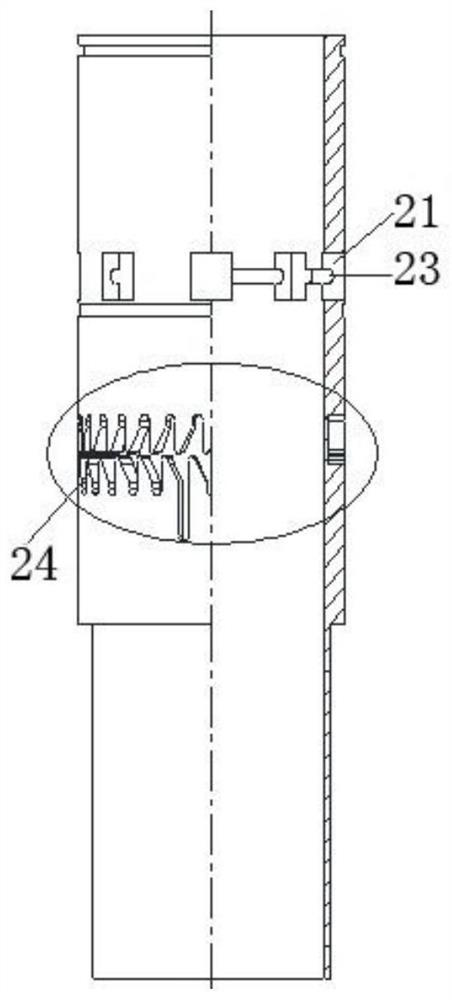

[0042] like figure 1 As shown in the figure, a chute counting type infinite-stage full-bore completion fracturing device includes a fracturing slip sleeve and a soluble information ball. The fracturing slip sleeve includes an upper joint 1, a lower joint 2, an outer sleeve 3, a fixed The sleeve 4 and the annular piston 5, the upper and lower ends of the outer sleeve are respectively connected with the upper and lower joints, the fixed sleeve is installed in the outer sleeve and is sleeved with the bottom of the extension of the upper joint, and the outer sleeve is connected to the extension of the upper joint. and the fixed sleeve to form an annular fracturing cavity, the annular piston is arranged in the annular fracturing cavity, and is laterally connected and positioned with the extension of the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com