Aspheric parameter error interference measurement method and system combined with astigmatism method positioning

A technology of interferometric measurement and positioning system, which is applied in the direction of measuring devices, instruments, and optical devices, etc. It can solve the problems of very high precision requirements for the assembly and adjustment of two-way pinholes and microscopic objective lenses, and a large system, and achieves simple structure and high precision. High, easy to adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

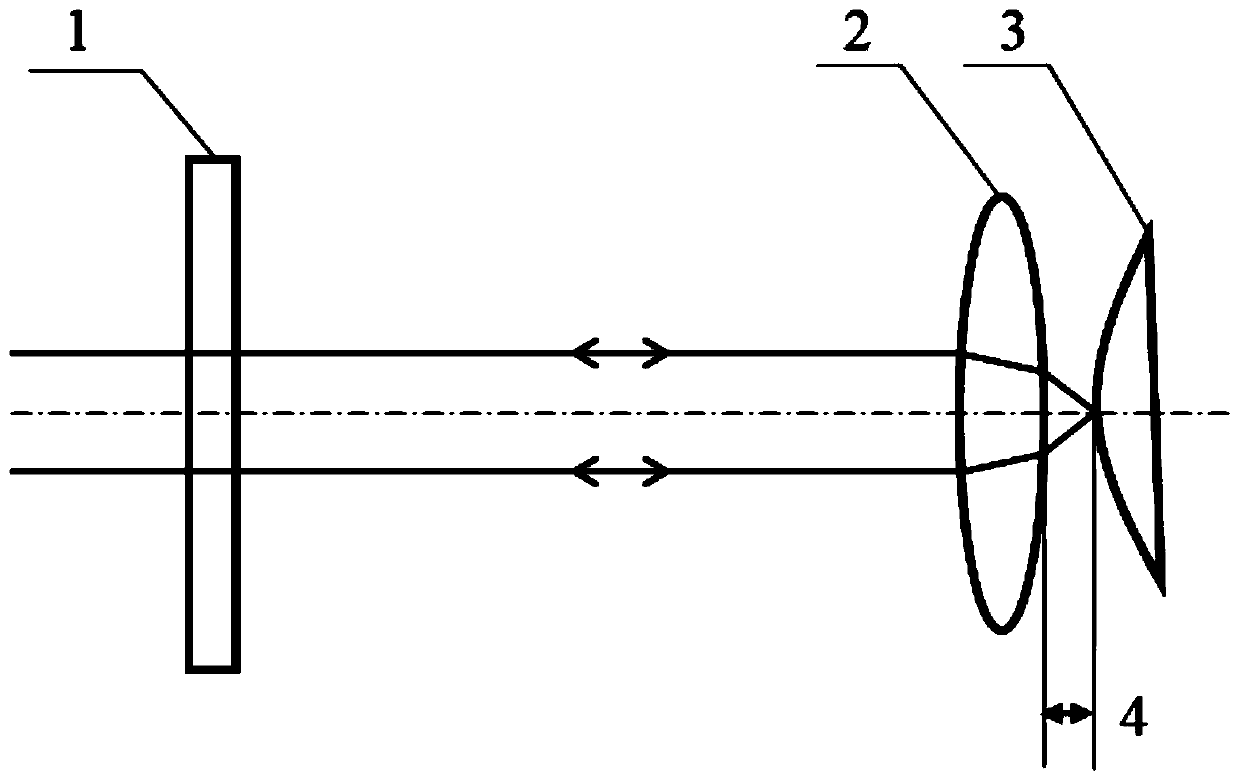

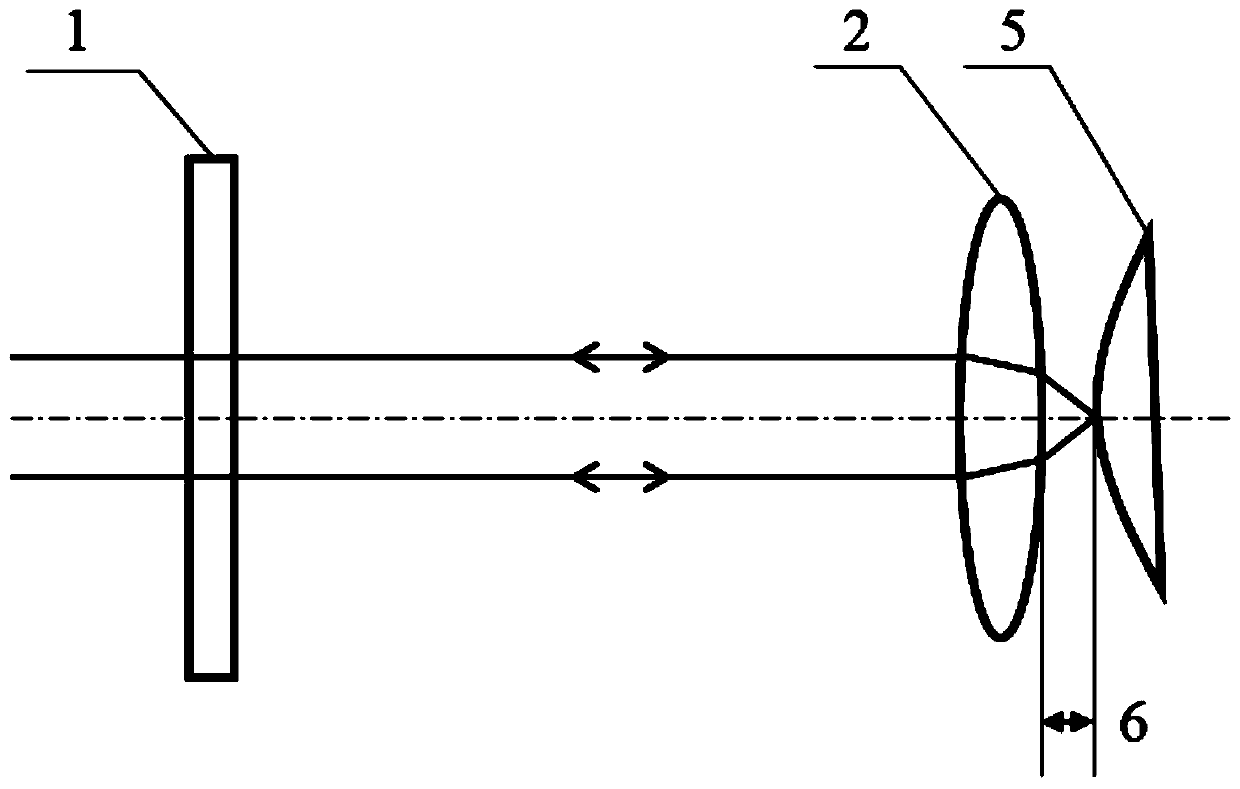

[0028] After long-term thinking and trial and error, the applicant replaced the existing patented laser differential confocal positioning system with the astigmatic positioning system. The astigmatism positioning system includes: polarization beam splitter, quarter-wave plate, focusing objective lens, converging lens, cylindrical mirror and four-quadrant detector. It has the advantages of simple structure, convenient installation and adjustment, and can avoid laser differential common The influence of the adjustment error of the focal system on the measurement accuracy. However, this is not a simple replacement, but a completely new change to the entire aspheric error interferometry method and system.

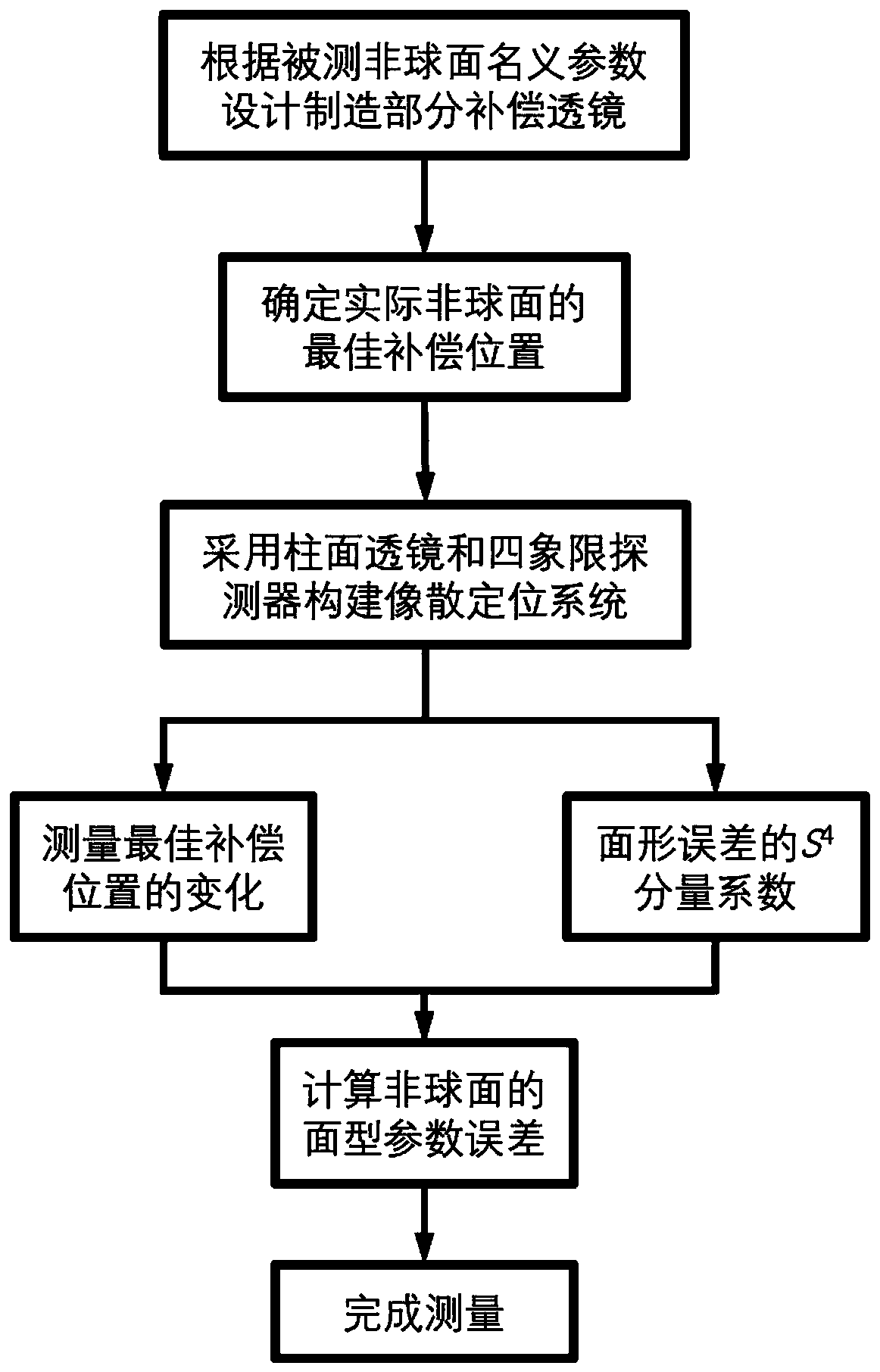

[0029] Such as figure 1 As shown, the aspheric parameter error interferometry method combined with astigmatism method positioning includes the following steps:

[0030] (1) Obtain the nominal parameters of the measured aspheric surface, use the optical design software to desi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com