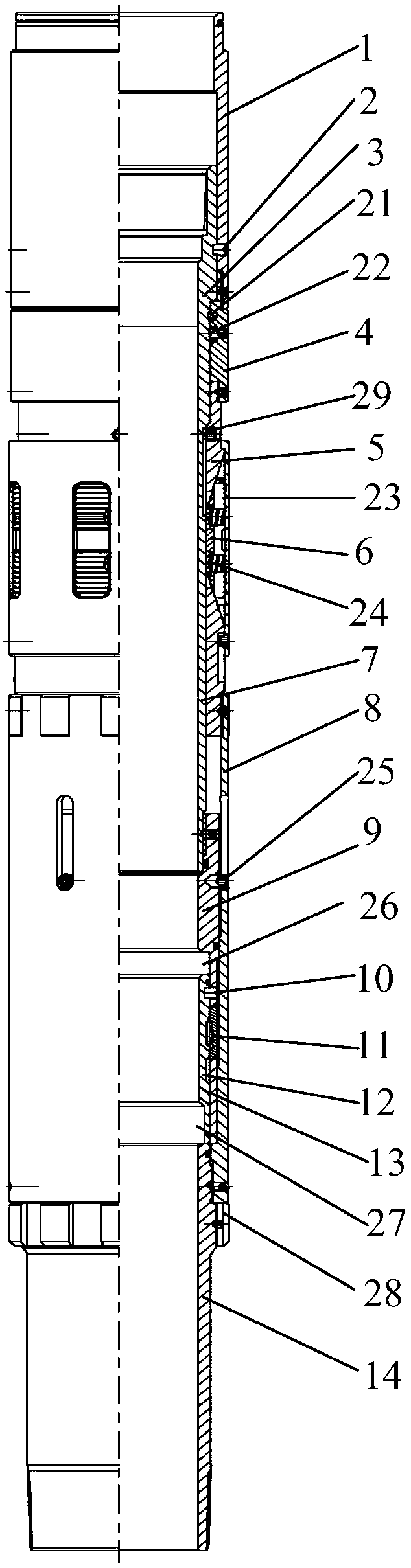

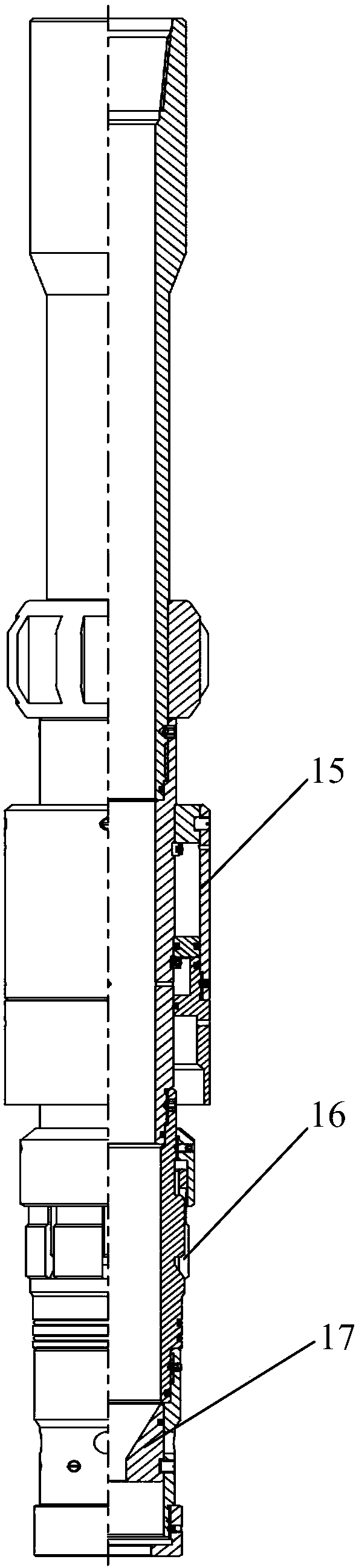

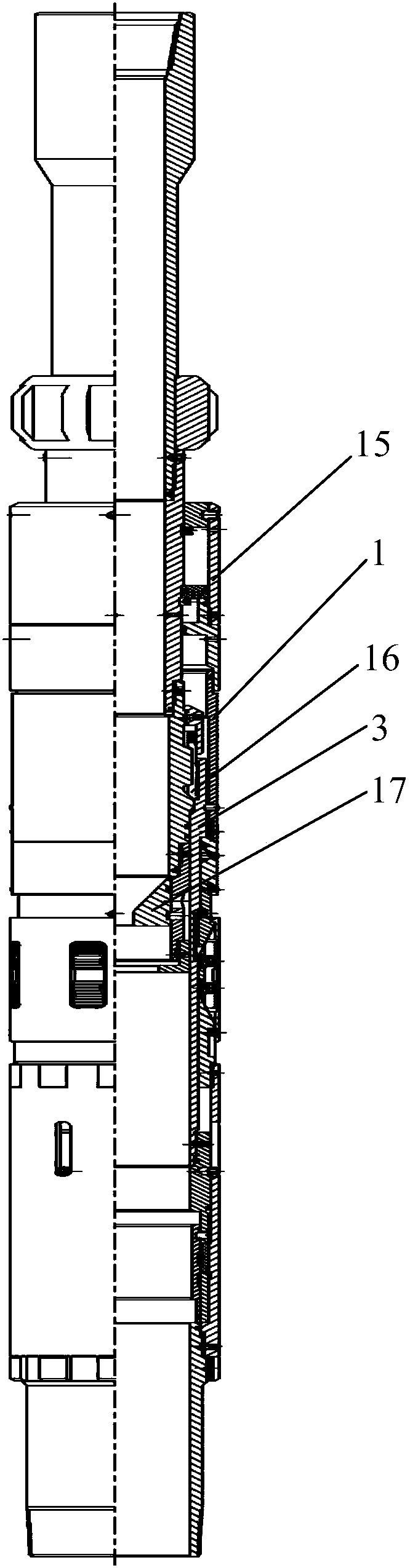

Recyclable bidirectional anchoring sieving pipe hanger and recyclable bidirectional anchoring sieving pipe system

A technology of hanger and screen pipe, which is applied in the direction of production fluid, wellbore/well parts, earthwork drilling and production, etc. It can solve the problems of cost waste, high cost, and large overall tool length, and achieve small overall length, cost saving, The effect of convenient wellhead construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the technical solutions and advantages of the present invention clearer, the exemplary embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Apparently, the described embodiments are only a part of the embodiments of the present invention, and are not exhaustive of all the embodiments. And in the case of no conflict, the embodiments and the features in the embodiments of the present invention can be combined with each other.

[0041] The inventor noticed during the invention process that there are no mature cementing and completion tools matching geothermal wells in China, and it is common to use cementing and completion tools for oil and gas wells in geothermal wells, but there are problems such as complex structure and high cost.

[0042] In view of the above deficiencies, embodiments of the present invention propose a retrievable two-way anchoring screen hanger, which will be des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com