Fracturing sliding sleeve

A fracturing sliding sleeve and sliding sleeve technology, applied in wellbore/well components, production fluids, sealing/packing, etc., can solve the problems of layered reforming series limitation, small diameter, unfavorable production logging, etc. To achieve the effect of simple structure, convenient operation and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

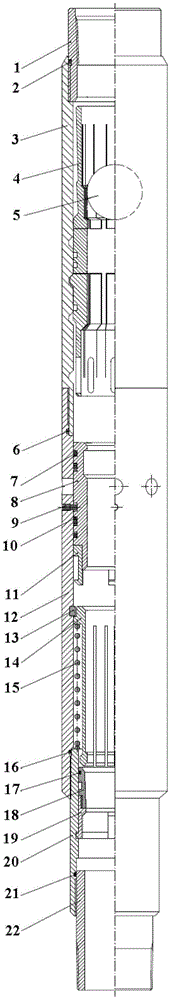

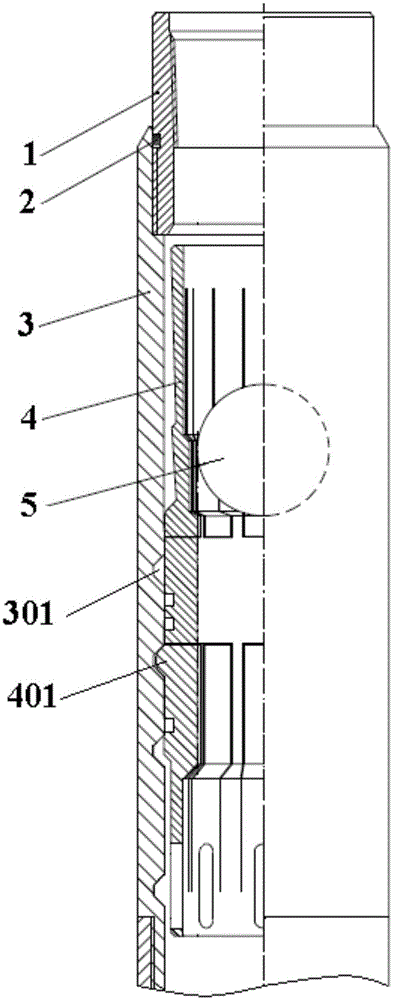

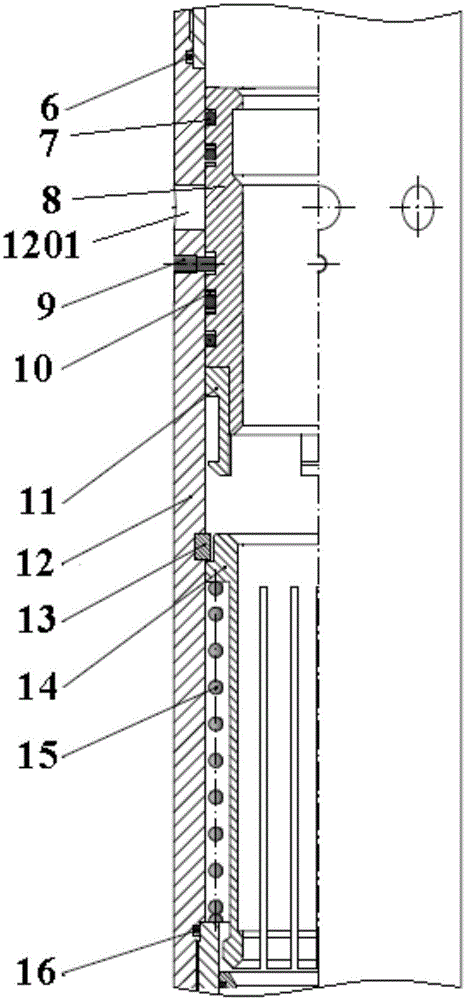

[0041] An embodiment of the present invention provides a fracturing sleeve, see figure 1 , and combined with Figure 2-4 , the fracturing sliding sleeve includes: upper joint 1, upper pipe body 3, lower pipe body 12, transition pipe body 20, lower joint 22, counting sliding sleeve 4, sliding sleeve mandrel 8, ball receiving claw 14, elastic claw Seat 18 and blocking ball 5;

[0042] The upper joint 1, the upper pipe body 3, the lower pipe body 12, the transition pipe body 20 and the lower joint 22 are sequentially connected;

[0043] The counting sliding sleeve 4 is located inside the upper tube body 3 and can move axially; the inner surface of the upper tube body 3 is provided with a plurality of first positioning grooves 301 along the axial directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com