Sliding sleeve structure for permanent completion and application method thereof

A sliding sleeve, permanent technology, applied in earthwork drilling, wellbore/well components, wellbore/well valve devices, etc., can solve the problem that the sliding sleeve cannot be selectively closed, oil and gas cannot be produced normally, and oil and gas production is affected To achieve the effect of improving oil and gas recovery, avoiding mis-opening and mis-closing, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

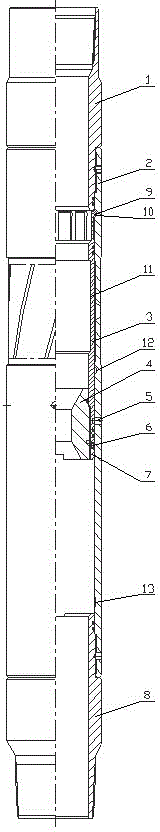

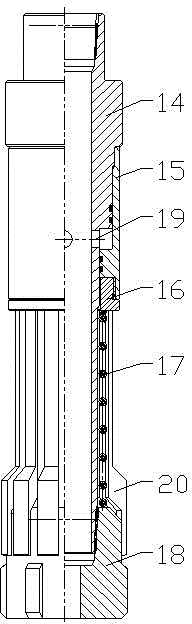

[0027] A sliding sleeve structure for permanent well completion, comprising an upper joint 1, a body 2, a movable sliding sleeve 3, an easy-drilling ball seat 4, a lower joint 8 and a self-locking mechanism, and the upper joint 1 and the lower joint 8 are respectively fixedly connected to The upper and lower ends of the body 2, the body 2 is provided with an injection groove, the movable sliding sleeve 3 is located in the body 2 to close the injection groove, and is connected to the body 2 through a pin 5, and the upper end of the movable sliding sleeve 3 is provided with a claw hook 9 , the inner wall of the movable sliding sleeve 3 is provided with a closing groove 11 that cooperates with the closing tool, and the easy-to-drill ball seat 4 is fixedly arranged on the lower part of the movable sliding sleeve 3 through threads, and the inner cavity of the body 2 is provided with a first hook that cooperates with the claw hook 9. A resistance groove 10 and a second resistance gro...

Embodiment 2

[0034] A method of using a sliding sleeve structure for permanent well completion. The sliding sleeve structure is connected to the position on the permanent completion pipe string that needs to be reconstructed in sections, and then it is lowered into the well. First, cement is injected for construction and waits for setting. After the cement slurry is solidified, The sliding sleeve is opened from the wellhead by throwing a ball to suppress pressure, and the continuous step-by-step production increase reconstruction construction is carried out; after the sliding sleeve is opened, the movable sliding sleeve is locked with the body through a self-locking mechanism.

[0035] When the reservoir for the stimulation and transformation needs to be stimulated again, the easy-drilling ball seat is drilled out. After the easy-drilling ball seat is drilled out, the self-locking between the movable sliding sleeve and the body is released, and the claw hook at the upper end of the movable s...

Embodiment 3

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0041] As a preferred embodiment of the present invention: as attached figure 1As shown, the present invention mainly includes an upper joint 1, a body 2, a movable sliding sleeve 3, an easy-drilling ball seat 4, a pin 5, a stop ring 6, a connecting screw sleeve 7, a lower joint 8, and the like. The upper joint 1 and the lower joint 8 are connected to the upper and lower ends of the main body 2 through threads, the upper part of the main body 2 has an injection groove, and the movable sliding sleeve 3 is located at the inner injection groove of the main body, and is connected by a pin 5 On the body 2 , the connecting screw sleeve 7 is connected to the lower end of the movable sliding sleeve 3 through the easy-to-drill ball seat 4 , and the backstop ring 6 is installed between the movable sliding sleeve 3 and the connecting screw sleeve 7 .

[0042] The inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com