Large-drift-diameter treatment-free downhole high-pressure temporary plugging tool and method

A treatment-free, large-diameter technology, which is applied in earthwork drilling, wellbore/well components, sealing/isolation, etc., can solve problems such as high construction risk, limited pressure bearing capacity, and small inner diameter of the center pipe, etc., to achieve guaranteed Safe, high pressure and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

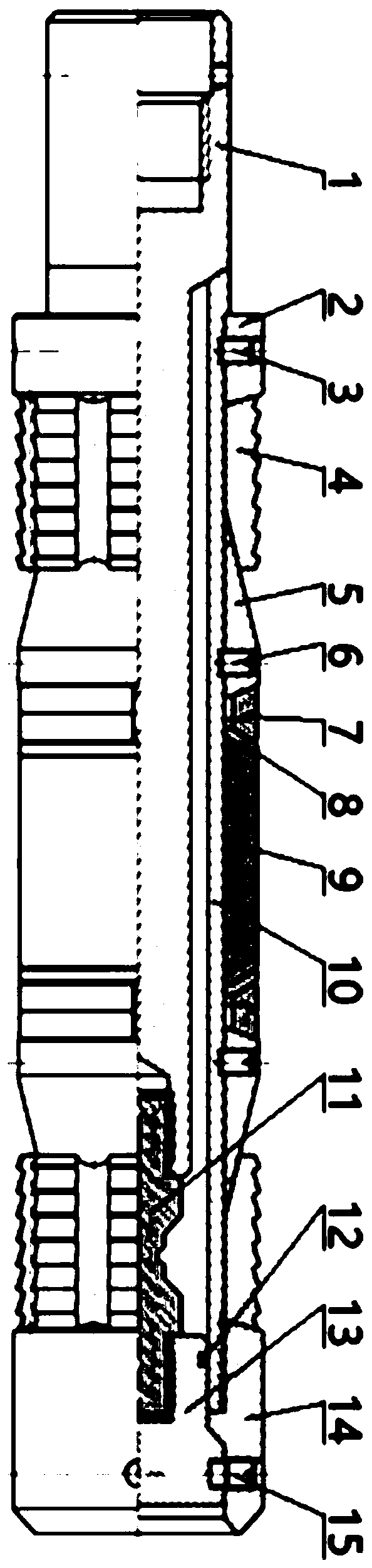

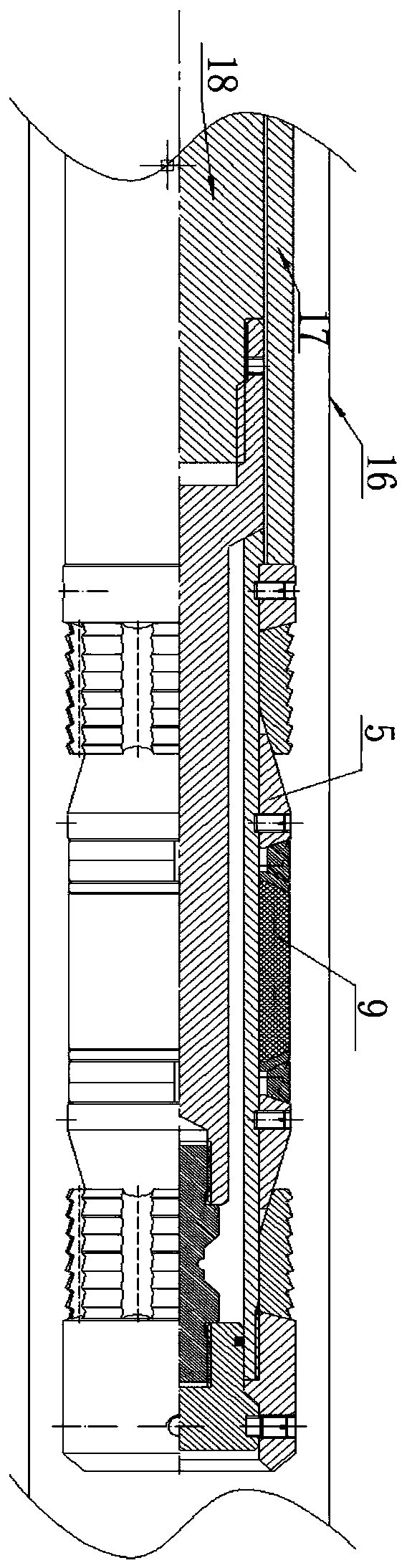

[0036] according to Figure 1-6 A large-diameter treatment-free downhole high-pressure temporary plugging tool is shown, including a hand-removing mechanism, a card sealing mechanism, a temporary plug 13, a support seat 14 and a fixing member; the lower end of the hands-free mechanism is detachably connected to the inner wall of the temporary plug 13 , the outer side wall of the upper part of the hand-losing mechanism is in contact with the upper end surface of the card sealing mechanism; the support seat 14 is sleeved on the outer side wall of the lower end of the temporary block 13 and fixed by a fixing member; the card sealing mechanism is arranged on the outer periphery of the hand-losing mechanism, and the sealing The lower end of the card mechanism is connected in the gap between the top of the support base 14 and the temporary plug 13 and is sealed with the temporary plug 13 by a seal.

[0037] It is preferable that the described fixing member adopts the starting shear ...

Embodiment 2

[0042] according to Figure 1-3 , Image 6 The large-diameter treatment-free downhole high-pressure temporary plugging tool shown is different from the first embodiment in that: the release mechanism includes a release rod 1 and a stress rod 11; the release rod 1 and the stress rod 11 is arranged up and down, and the outer side walls of the upper and lower ends of the stress rod 11 are respectively connected with the inner side walls of the throwing bar 1 and the temporary blockage 13 with screws.

[0043] Further, the stress rod 11 is a columnar body with an annular groove 19 for breaking in the middle.

[0044] In actual use, when the sealing mechanism moves downward under the thrust of the seat sealing tool, it completes contact with the inner wall of the casing 16, clamps, and squeezes the seal. The weak point provided in the middle part, that is, the annular groove 19, is broken, and the tool is completely lost.

[0045] In a specific application, the stress rod 11 ado...

Embodiment 3

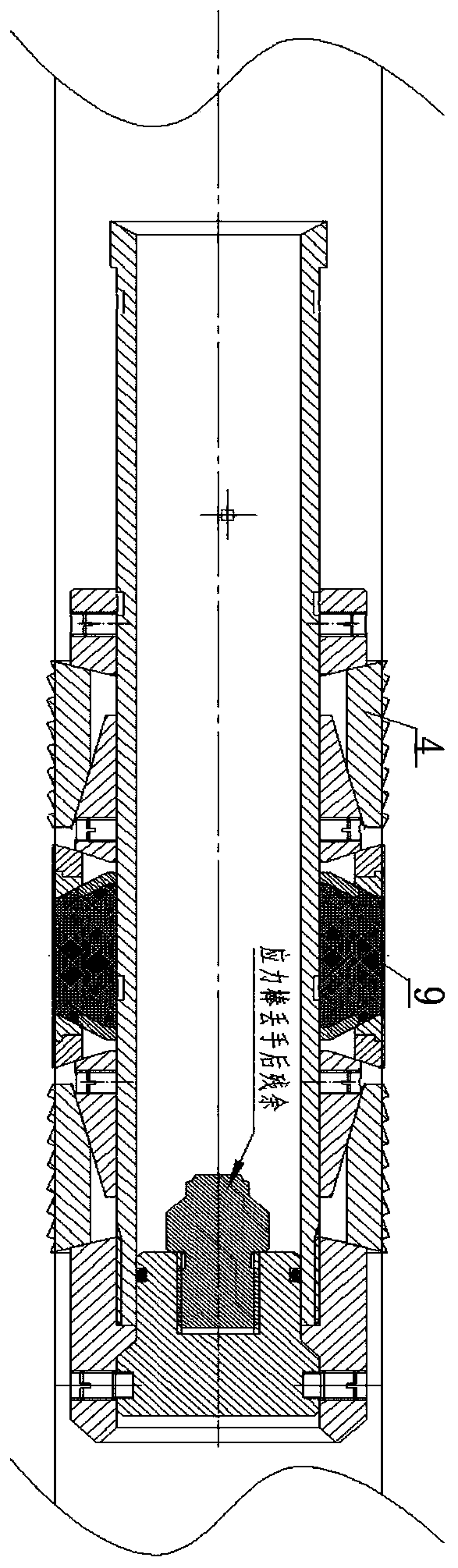

[0049] according to Figure 1-5 The large-diameter treatment-free downhole high-pressure temporary plugging tool shown is different from the first embodiment in that the sealing mechanism includes a movable sleeve 2, slips 4, a cone 5, and a second anti-seat shear nail 6 , protective umbrella 7, protective ring 8, rubber tube 9 and central tube 10; Outside; the rubber tube 9 is socketed in the middle of the central tube 10, and the retaining ring 8, the umbrella 7, the cone 5 and the slips 4 are arranged symmetrically on both sides with the rubber tube 9 as the center; the cone 5 The second anti-seat shear nail 6 is fixed to the central tube 10; the movable sleeve 2 is in contact with the upper slip 4, and is fixed to the central tube 10 by the first anti-seat shear nail 3; the upper end of the central tube 10 is connected to When the hands-off mechanism contacts, the lower end of the central tube 10 is connected in the gap between the support seat 14 top and the temporary bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com