Variable-diameter fracturing valve

A fracturing valve and variable technology, applied in the direction of wellbore/well valve device, production fluid, wellbore/well components, etc., can solve the problems that cannot meet the development needs of oil and gas fields, and cannot realize layered reconstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

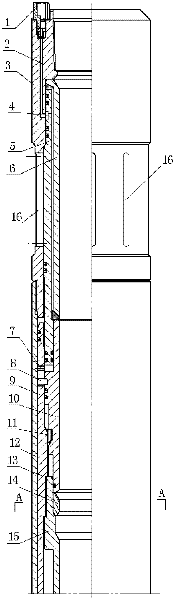

[0020] Embodiment 1: Taking a variable-diameter fracturing valve as an example, the present invention will be further described in detail.

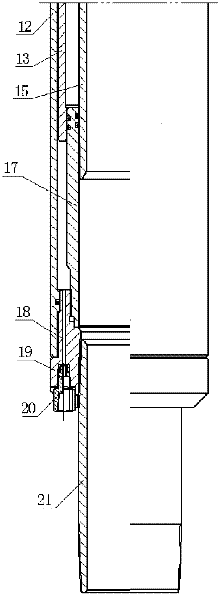

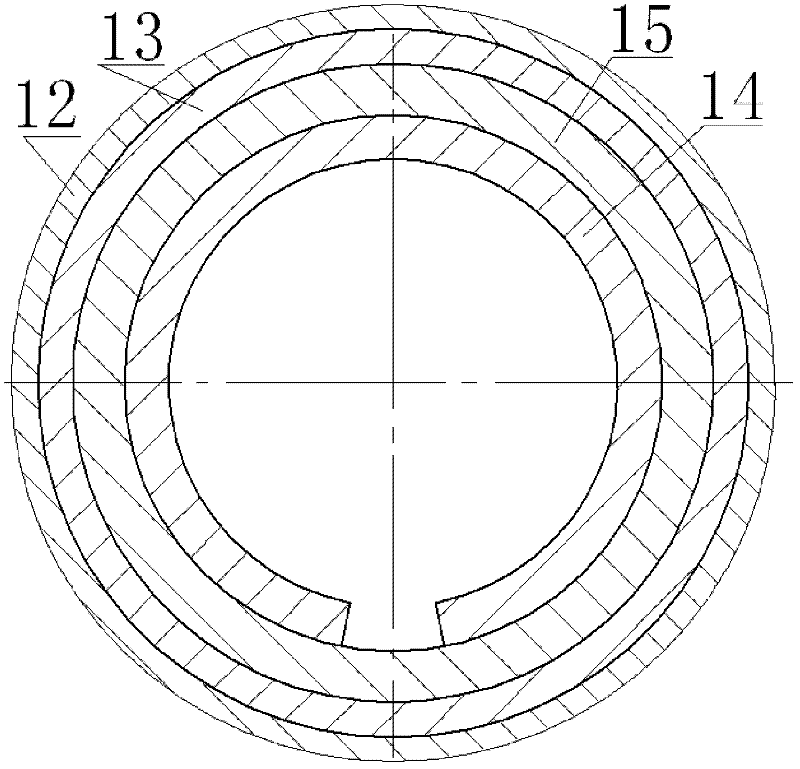

[0021] refer to figure 1 . The variable diameter fracturing valve of the present invention includes an upper pressure head 1, an upper pressure channel 2, an upper joint 3, a liquid outlet hole 4, an outer sliding sleeve 5, an inner sliding sleeve 6, a liquid inlet hole 7, a shear pin 8, a guide Sleeve 10, lock ring 11, cylinder liner 12, upper connecting cylinder 13, reducing ball seat 14, support seat 15, fracturing channel 16, lower connecting cylinder 17, lower pressure transmission channel 18, lower transmission pressure body 19, lower transmission Crimping head 20 and lower joint 21.

[0022] The upper end of the center hole of the upper joint 3 has an internal thread, which can be connected to the fracturing casing string; there is an axial pressure-uploading channel 2 on the upper end wall of the upper joint 3, and the inner dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com