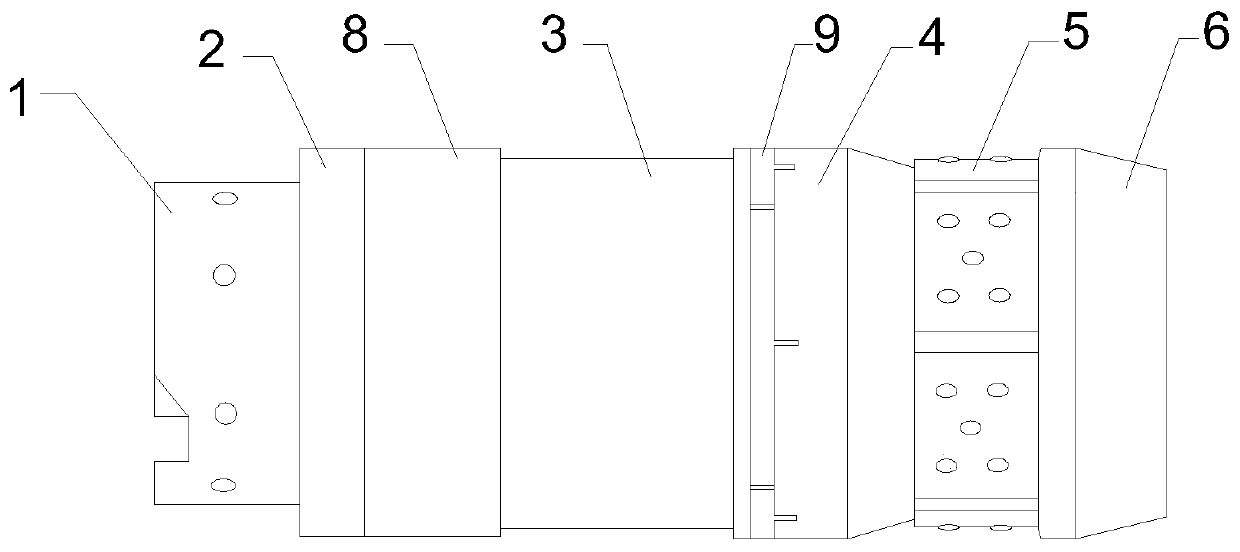

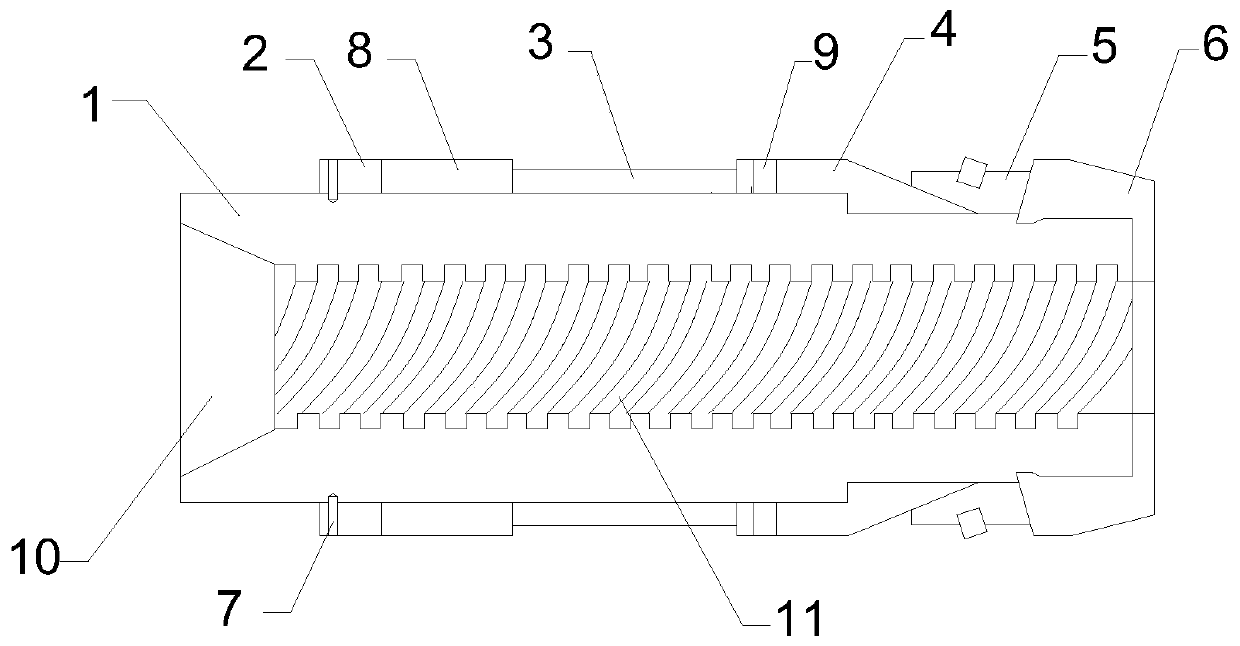

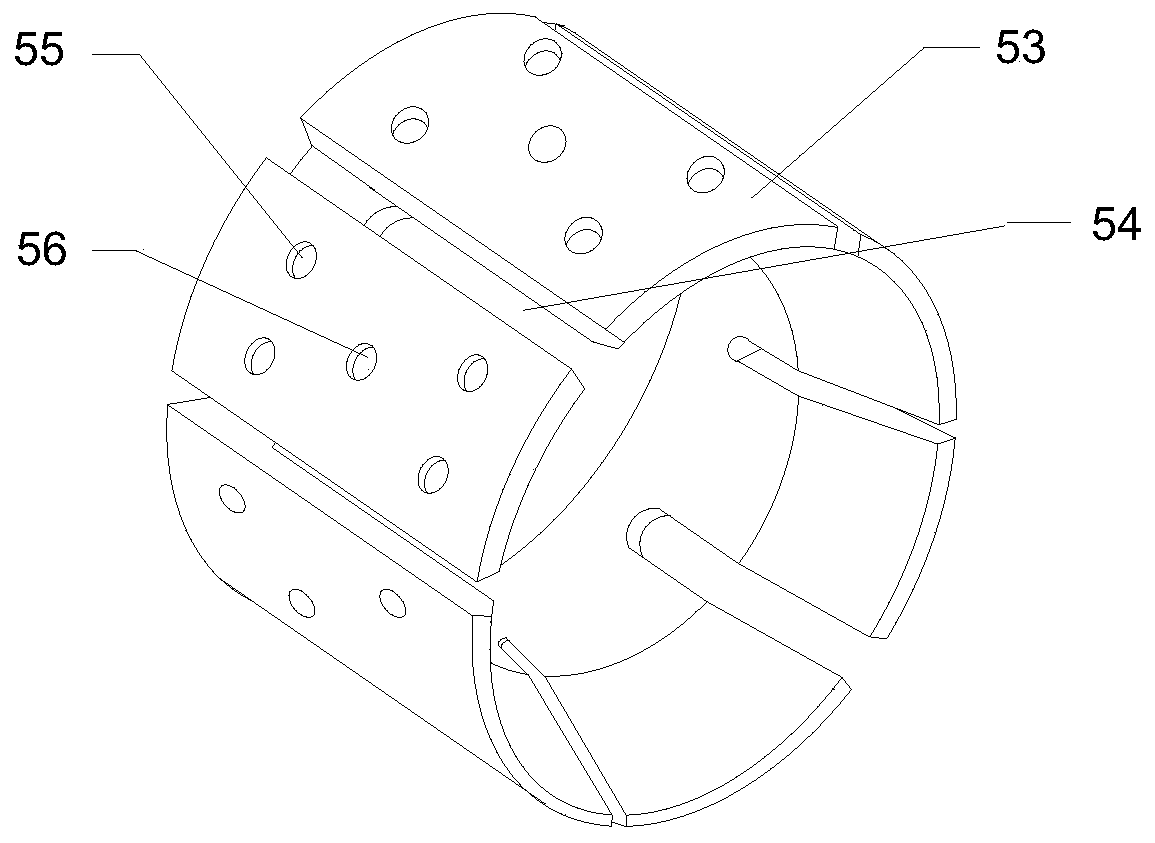

Single slip soluble bridge plug

A single-slip, bridge-plug technology, applied in wellbore/well components, earthmoving, sealing/packing, etc., can solve the problems of reduced flowback efficiency, long double-slip bridge plug, easy to block wellbore, etc. , to achieve the effect of improving sealing reliability, improving flowback efficiency, and strong anchoring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] The rapidly dissolving high-strength and high-elongation magnesium alloy described in this embodiment is composed of the following elements in mass percentage: Gd 2.5%, Y 1.0%, Al 1.0%, Zn 0.5%, Zr 0.4%, Sc 0.01%, Cu 1.5%, Li 0.25%, Ni 0.25%, Ga 0.25%, In 0.25%, and the rest is Mg.

[0085] The preparation method of the fast-dissolving high-strength and high-elongation magnesium alloy described in this embodiment, the specific steps are as follows:

[0086] S1. Weigh pure Mg, pure Al, pure Zn, pure Ga, pure In, Mg-Gd master alloy, Mg-Y master alloy, Mg-Zr master alloy, Mg-Sc master alloy, Mg- Cu master alloy, Mg-Li master alloy, Mg-Ni master alloy;

[0087] S2. Preheating the raw materials except pure Ga in step S1 at 150° C. for 2 hours;

[0088] S3. Mix all the raw materials, heat the mixed raw materials to 720°C in a crucible resistance furnace, melt for 30 minutes, add the first refining agent, refine for 30 minutes, remove the inclusions in the melt, and then use...

Embodiment 2

[0095] The fast-dissolving high-strength and high-elongation magnesium alloy described in this embodiment is composed of the following elements in mass percentage: Gd 1.5%, Y 0.5%, Al 0.1%, Zn 0.1%, Zr 0.2%, Sc 0.001%, Cu 0.1%, Li 0.01%, Ni 0.01%, Ga 0.01%, In 0.01%, and the rest is Mg.

[0096] The preparation method of the rapidly dissolving high-strength and high-elongation magnesium alloy described in this embodiment is the same as that in Embodiment 1.

Embodiment 3

[0098] The fast-dissolving high-strength and high-elongation magnesium alloy described in this embodiment is composed of the following elements in mass percentage: Gd 14.5%, Y 2.0%, Al 2.0%, Zn 1.0%, Zr 0.5%, Sc 0.02%, Cu 2.0%, Li 0.5%, Ni 0.5%, Ga 0.5%, In 0.5%, and the rest is Mg.

[0099] The preparation method of the fast-dissolving high-strength and high-elongation magnesium alloy described in this example is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com