Whole path and infinite stage segmented fracturing tool and use method thereof

A staged fracturing and unlimited stage technology, which is applied in the direction of earthwork drilling, production fluid, drilling equipment, etc., can solve the problems of stage limit of staged fracturing, difficult workover operations, opening sliding sleeves in advance, etc., to achieve Reduce working time, save working time, and facilitate production adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

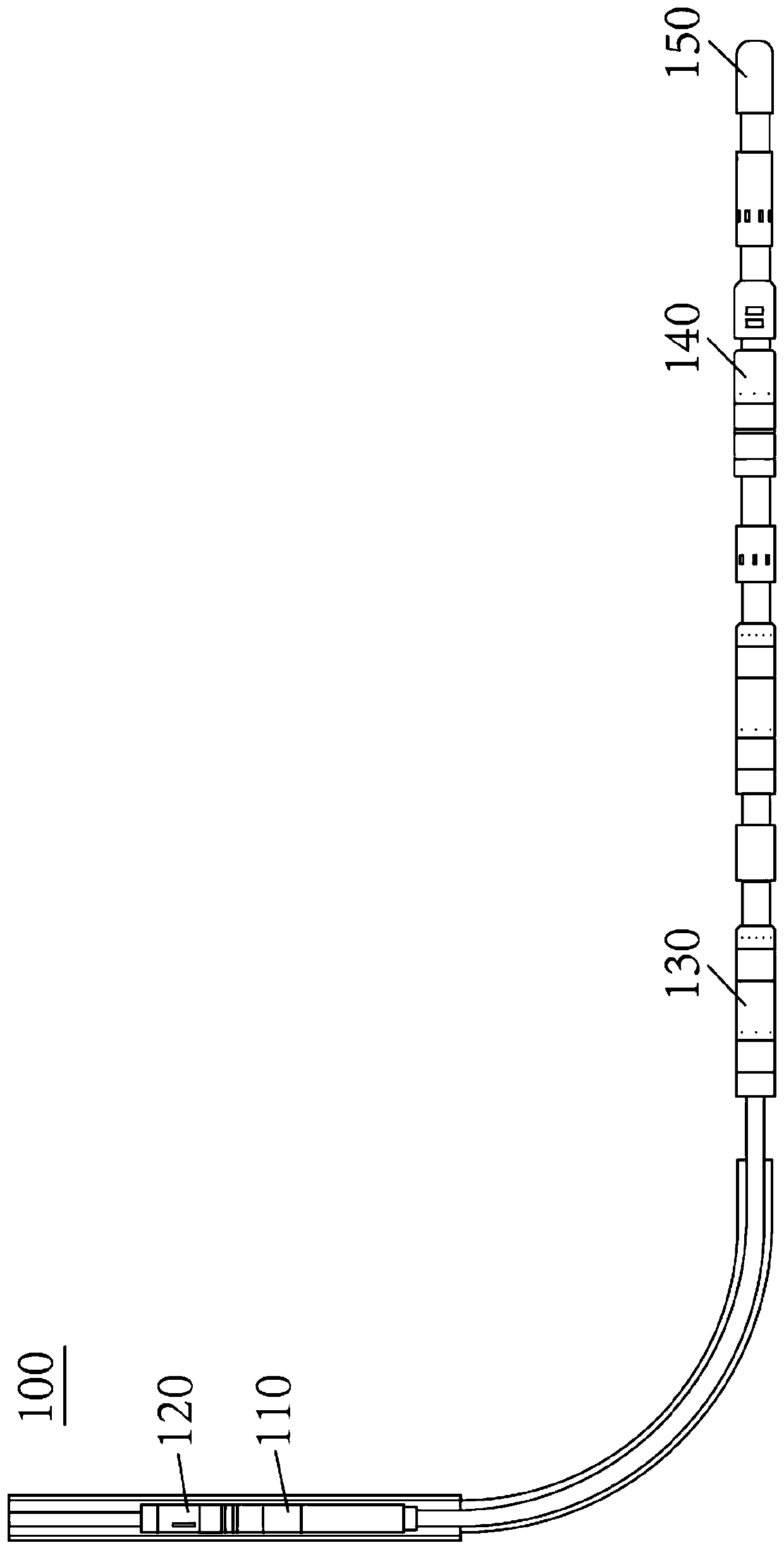

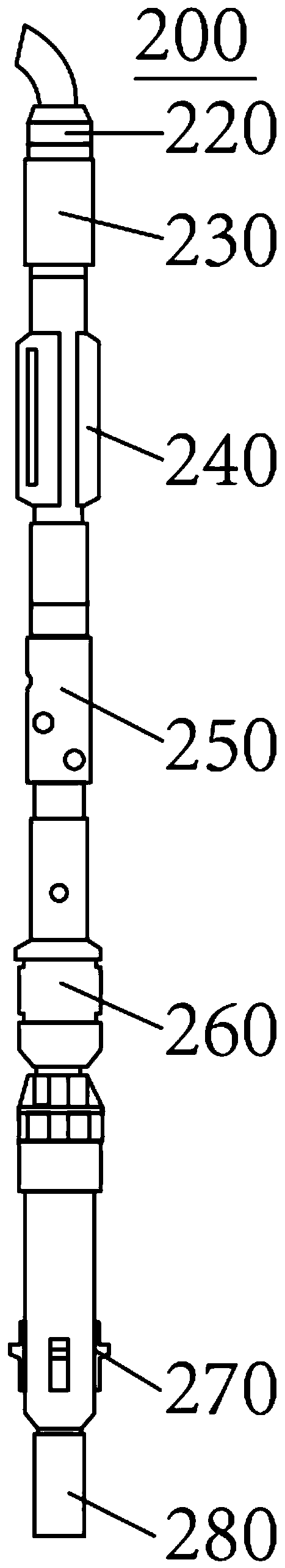

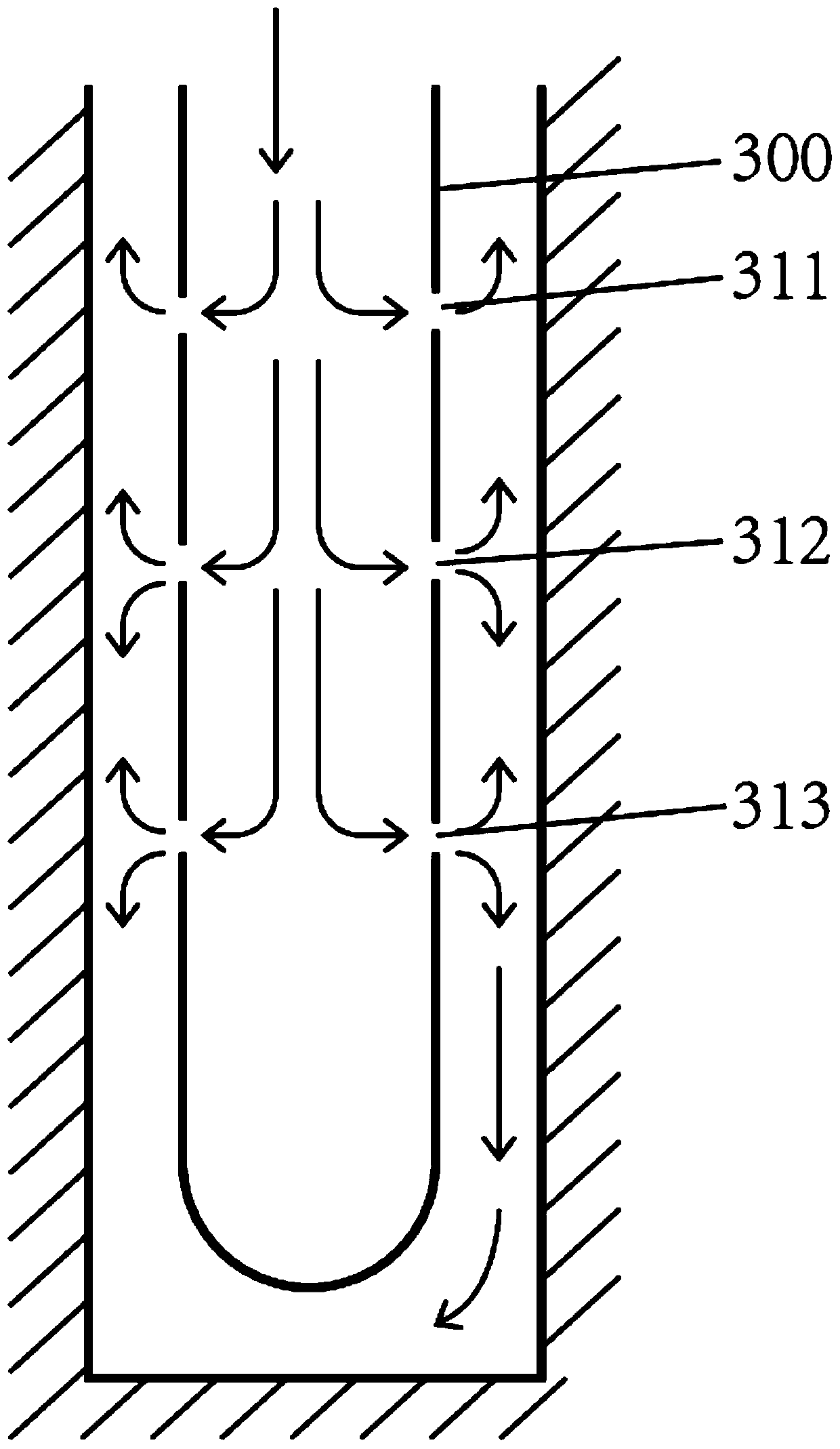

[0058] Please refer to Figure 1-7 , which is a preferred embodiment of the present invention, the full-bore, infinitely staged fracturing tool includes a casing 300, an open hole packer assembly 100 outside the casing and a bottom packer assembly 200; wherein the casing 300 is provided with a plurality of liquid outlet holes 310; the open hole packer assembly 100 outside the casing includes a plurality of outer casing packers 130 and a bottom circulation assembly 150, and a plurality of outer casing packers 130 are sleeved Outside the casing 300 , and the upper and lower parts of each outlet hole 310 are provided with the outer pipe packer 130 , and the bottom circulation assembly 150 is installed at the bottom of the casing 300 The bottom packer assembly 200 is sleeved in the casing 300, including a coiled tubing 210, a perforating gun 250 and a bottom packer 260, and the perforating gun 250 is installed on the coiled tubing 210, In communication with the coiled tubing 210 ...

Embodiment 2

[0073] The method for using the full-bore, infinitely staged staged fracturing tool in Embodiment 1 comprises the following steps:

[0074] S1. Presetting the casing 300 so that each of the liquid outlet holes 310 corresponds to the design position of the corresponding fracturing interval;

[0075] S2. Lower the outer casing packer assembly 100 to the design position outside the casing 300, so that the upper and lower parts of each outlet hole 310 are provided with the outer packer 130;

[0076] S3. During fracturing, run the bottom packer 260 through the coiled tubing 210, and set the bottom packer 260 at the designed position of the first fracturing interval;

[0077] S4. Carry out the first stage of fracturing operation;

[0078] S5. After the first fracturing operation is completed, lift the coiled tubing 210 to unseal the bottom packer 260, and drag the bottom packer 260 to the design position of the second fracturing interval to set the Bottom packer 260, and carry out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com