Drilling device and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

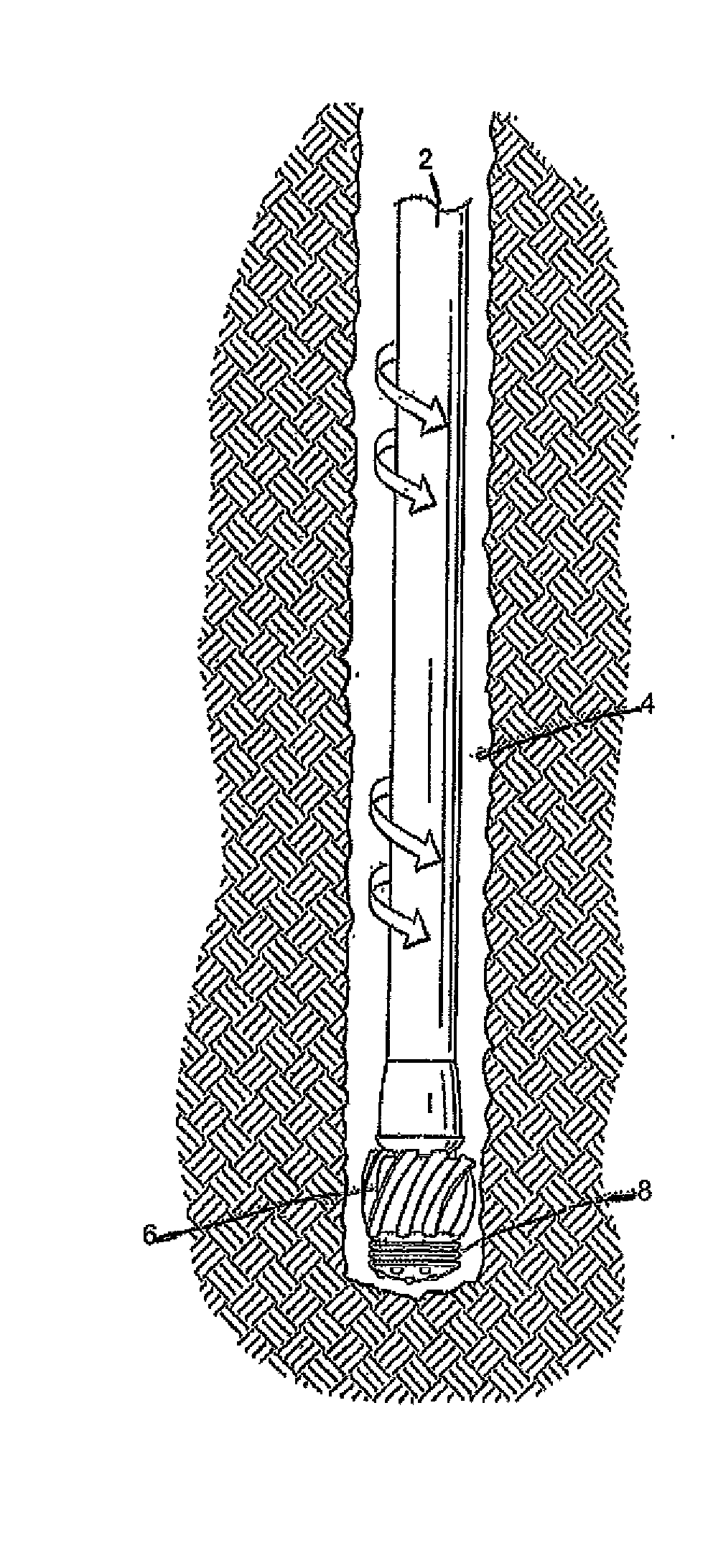

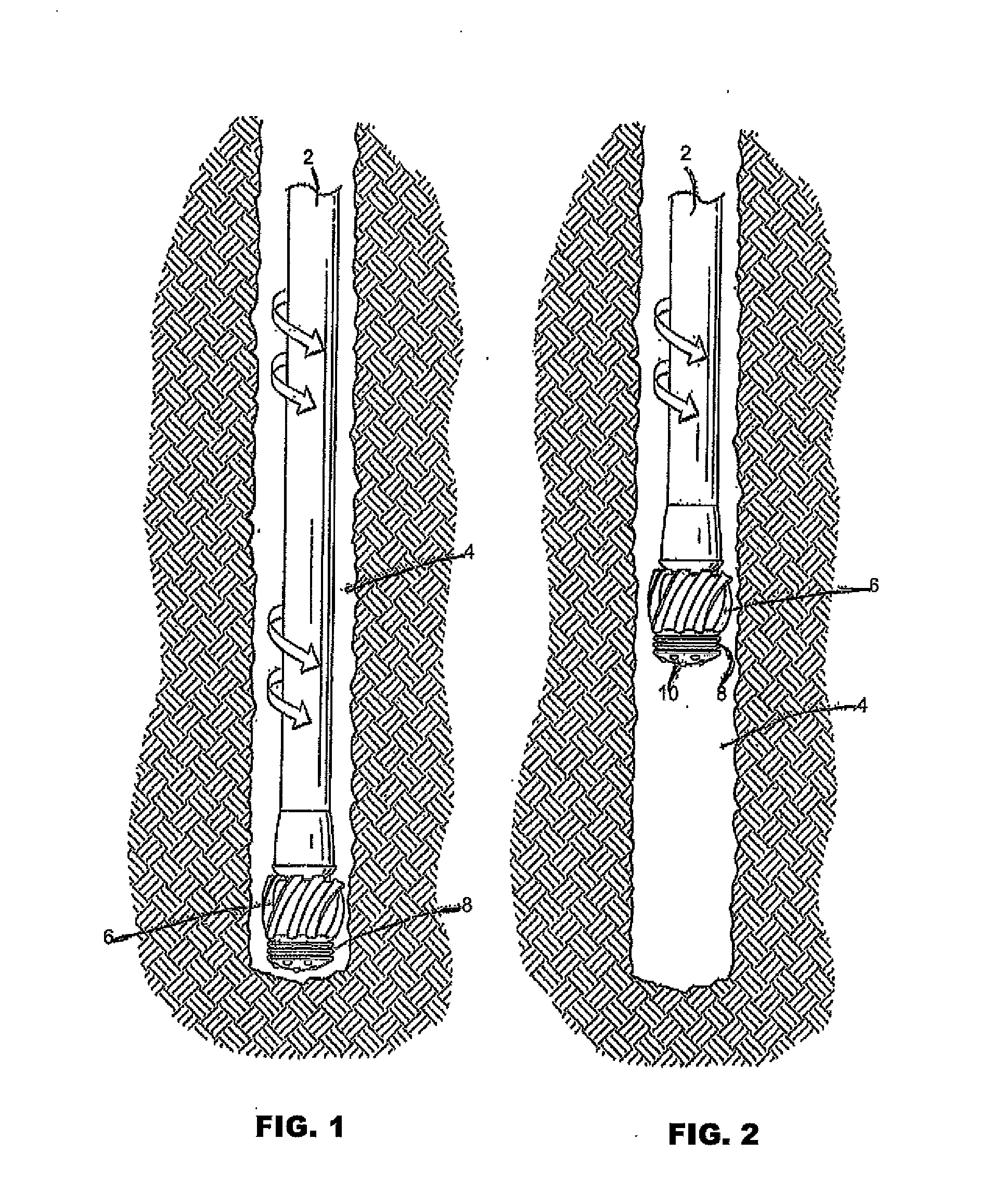

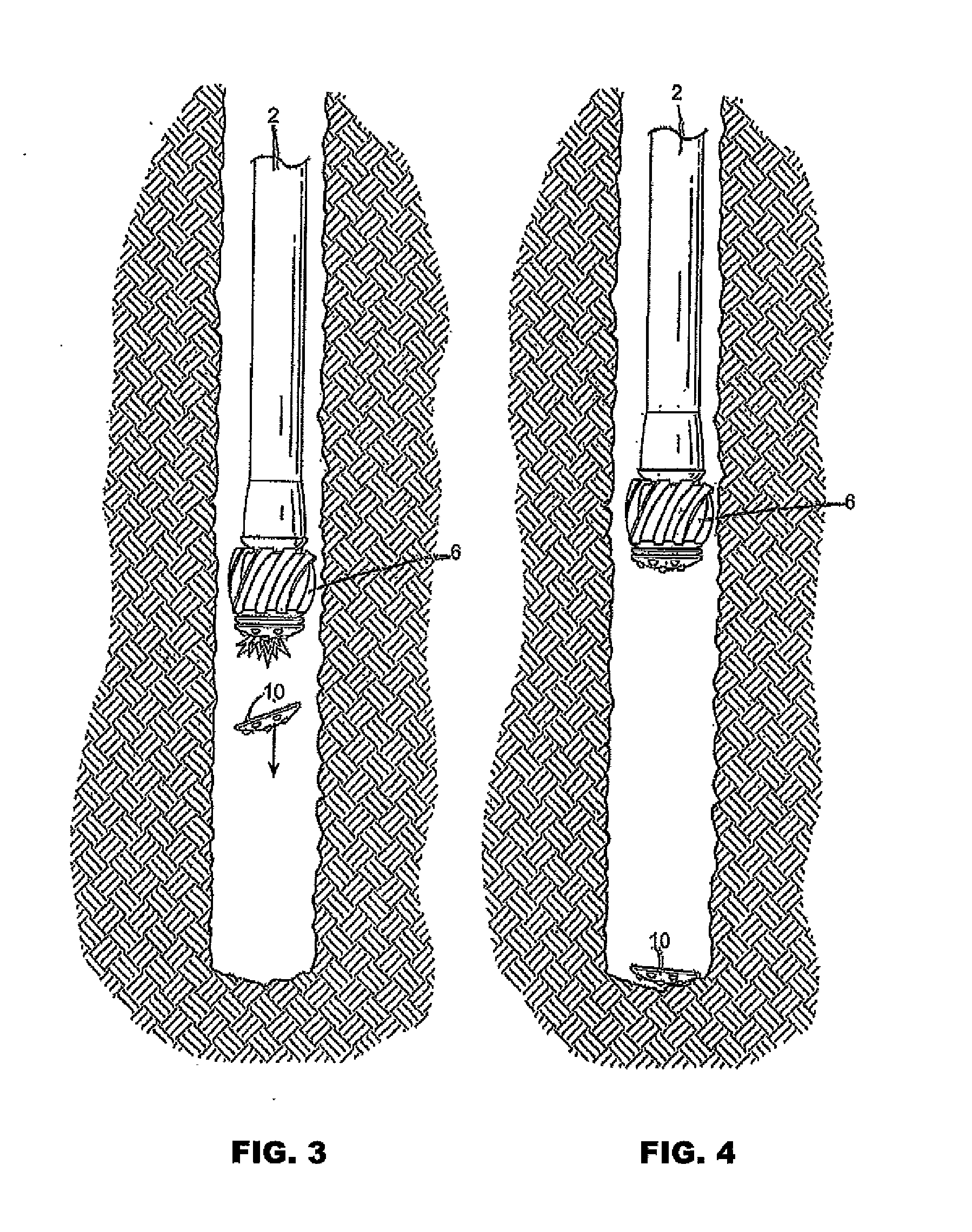

[0019]The drawing figures demonstrate a forward, or distal, end of a drill string with the drill bit assembly comprised of a mandrel and associated cutting faces. The drill string in use may be of substantial length, and may be thousands of feet long. The drill string is formed by joining multiple sections of pipe. The drawing figures demonstrate only the most forward or distal section of pipe 2, and depict only the last few feet of a hole 4 that may be thousands of feet deep.

[0020]Affixed to the end of the most distal pipe section, and at the most distal end of the pipe section, is a mandrel 6. The most distal end of the mandrel is a plurality of drill cutting faces 8. The drill cutting faces are used to cut away earth, rock, and other geological material. In one embodiment, the cutting faces are formed as a plurality of disks having cutting material 20, such as PCD, embedded therein. The plurality of cutting faces is present sequentially on the mandrel as shown in the drawing figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com