Large-diameter offshore rock-socketed pile foundation pit excavation method

A technology of rock-socketed piles and large diameters, which is applied in drilling equipment and methods, earthwork drilling, underwater drilling, etc., can solve the problems that the construction is greatly affected by the weather, the construction is difficult, and the effective construction period is short, so as to reduce the Wear and labor intensity of workers, reduce work difficulty and workload, and improve the effect of excavation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following will further explain how the present invention is implemented in conjunction with the accompanying drawings and specific implementation methods.

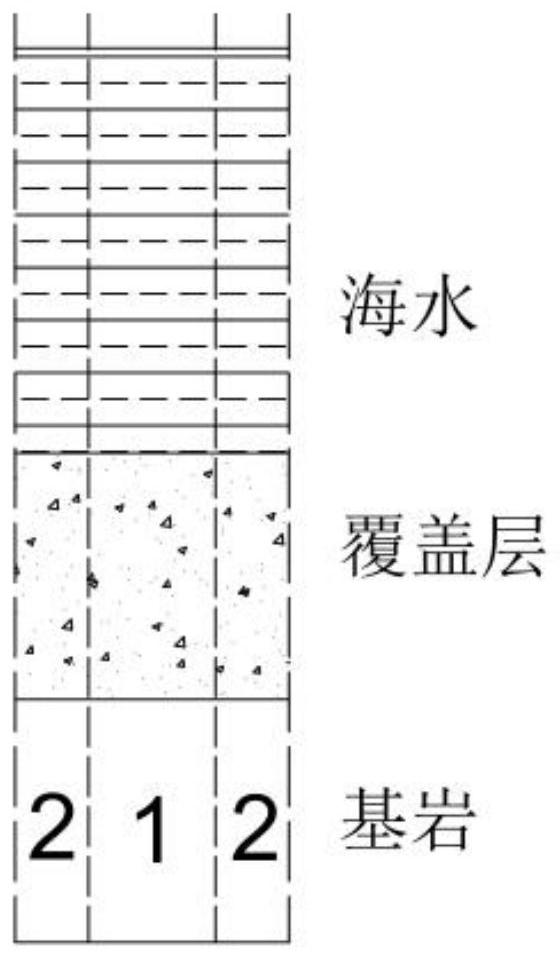

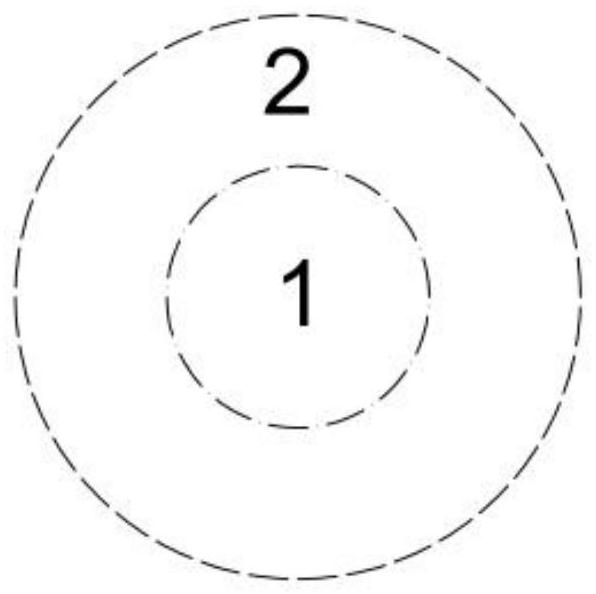

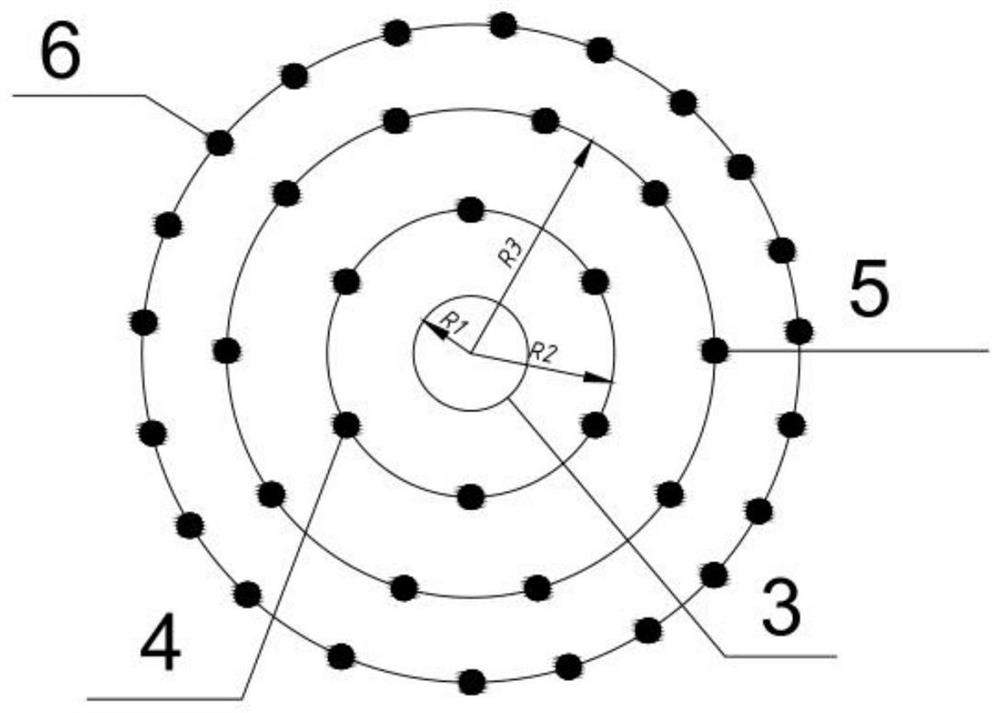

[0035] A large-diameter offshore rock-socketed pile foundation pit excavation project, the diameter of the foundation pit is 8m; the covering layer is relatively thin, and the thickness of the bedrock covering layer is about 8m; the depth of the overlying sea water is 30m; the bedrock is mainly medium and strong weathered rock; The tidal range and wind waves in the environment are large, the construction needs to be fast and the cost is low, which brings great difficulties to the construction. Due to the requirements of the large-diameter turning machine on the use environment and the problem of difficulty in deployment, a large-diameter offshore rock-socketed pile of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com