Intelligent drilling frame

A smart drilling and frame technology, applied in the direction of drill pipe, drill pipe, earth cube drilling, etc., can solve the problems of high dust content in the working environment, low maintenance efficiency, work hazards, etc., achieve high practical value and economic value, reduce work quantity and the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

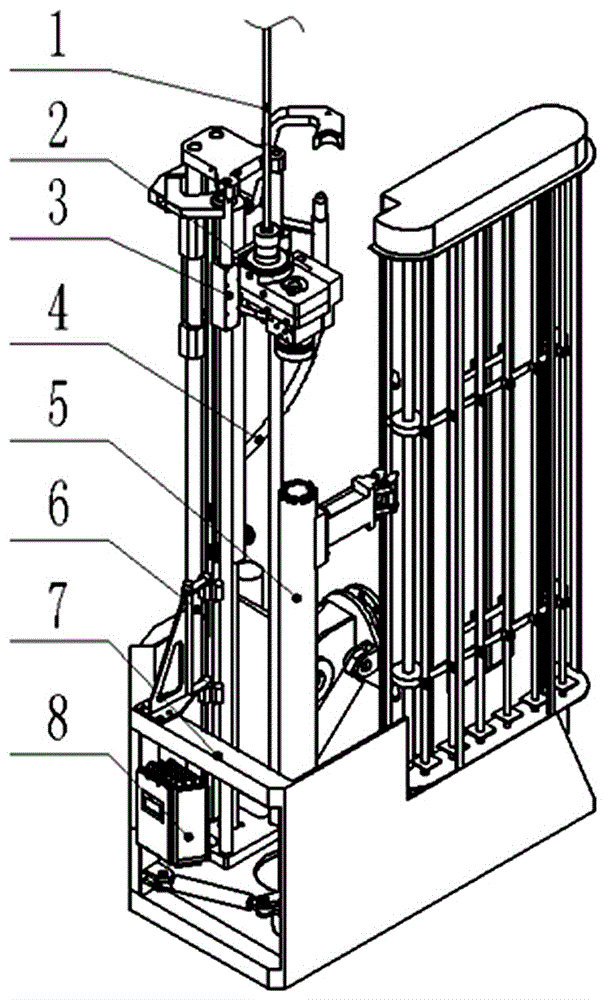

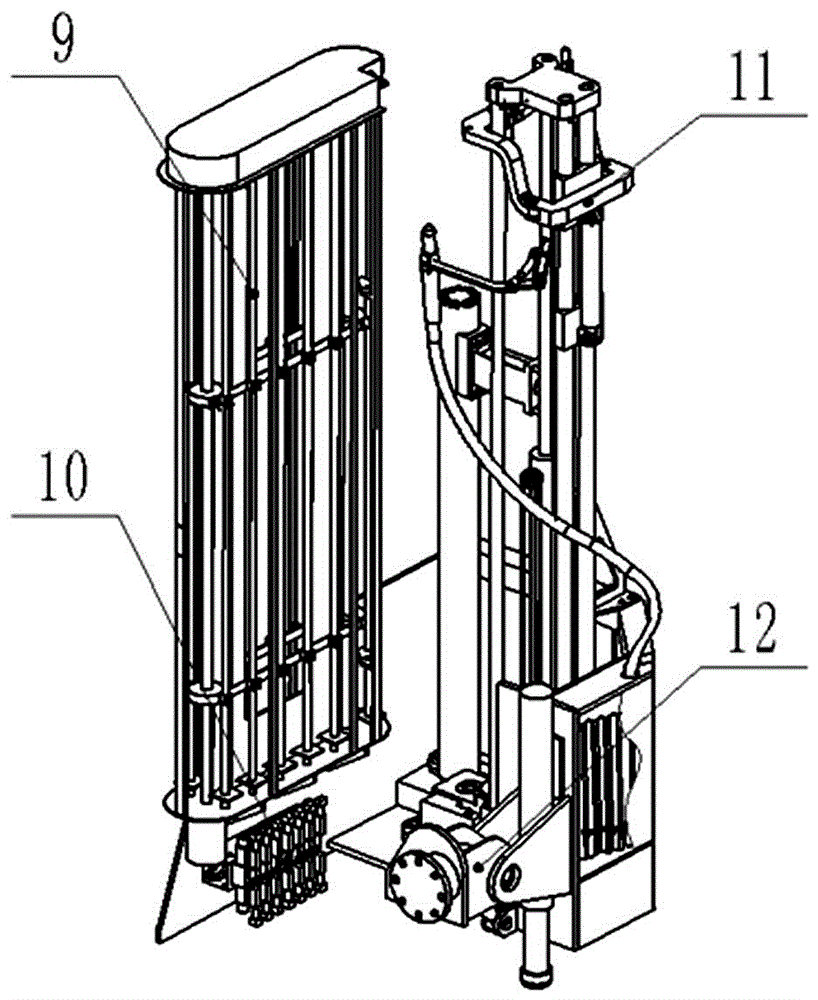

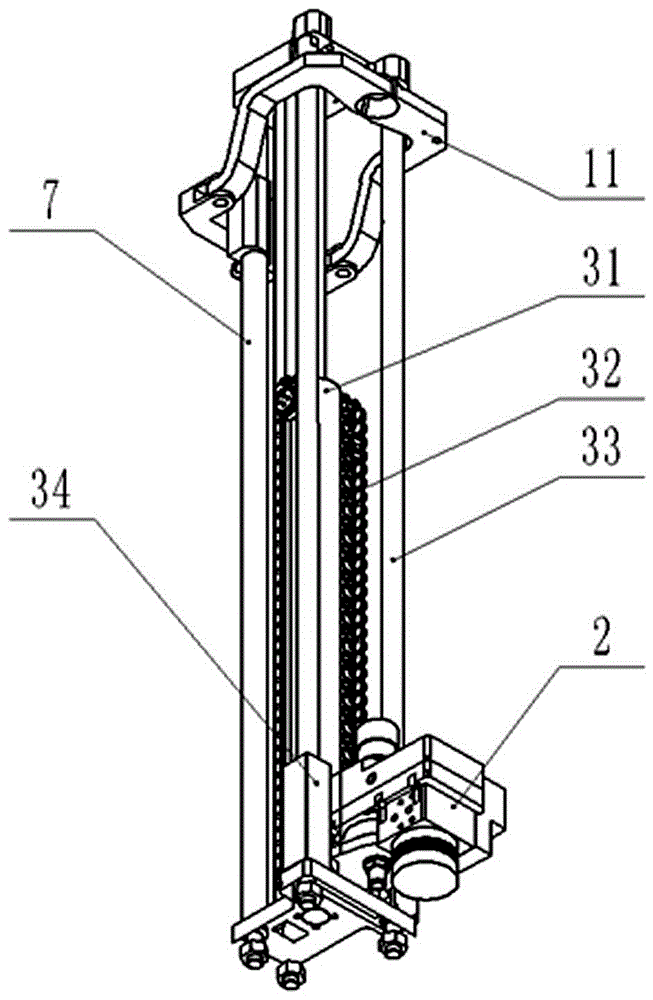

[0024] figure 1 and figure 2 They are structural schematic diagrams of two different angles of the present invention, such as figure 1 , 2 As shown, an intelligent drill rack includes a drill pipe 1, a drill box 2, a lifting mechanism 3, a drug injection system 4, a manipulator 5, a drill pipe clamping mechanism 6, a frame 7, an electrical control system 8, and a bolt warehouse 9 , a hydraulic system 10, a clamping mechanism 11 and a connection swing mechanism 12, the connection swing mechanism 12 is arranged on the outside of the frame 7, the drill pipe clamping mechanism 6, the drug roll injection system 4, the bolt warehouse 9, the manipulator 5, the electrical The control system 8 and the hydraulic system 10 are all arranged in the frame 7, the drill rod 1 is fixed in the drill rod clamping mechanism 6, the bottom of the drill rod 1 is provided with external threads, and the upper surface of the drill box 2 is arranged with the drill rod. 1. A threaded hole matching th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com