Method for pre-splitting of roof through multipoint dispersed parallel-type blastholes in fully mechanized mining face

A fully-mechanized mining face and face technology, which is applied to drilling equipment and methods, earthwork drilling, and drilling using explosives, etc., can solve the problems of long drilling time, large suspended roof area, and labor-intensive, etc., and achieve reduction The effect of impact range, reduction of overhang area, and reduction of stuck pipe phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

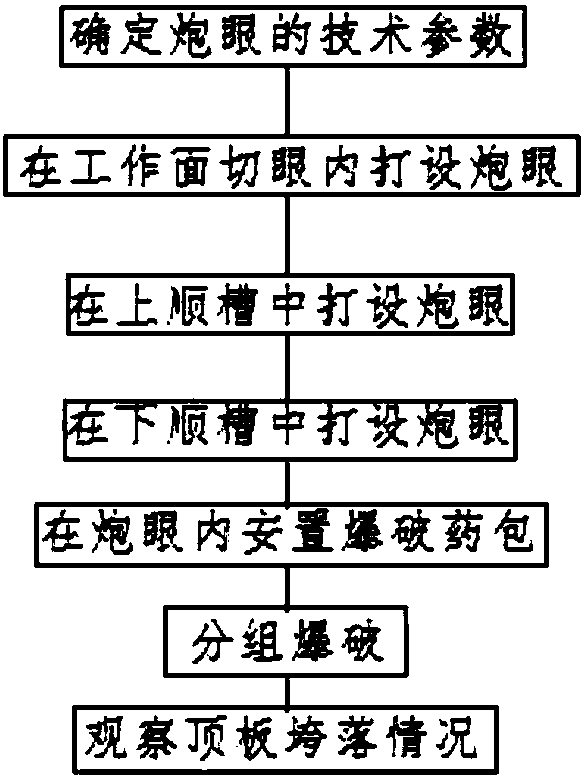

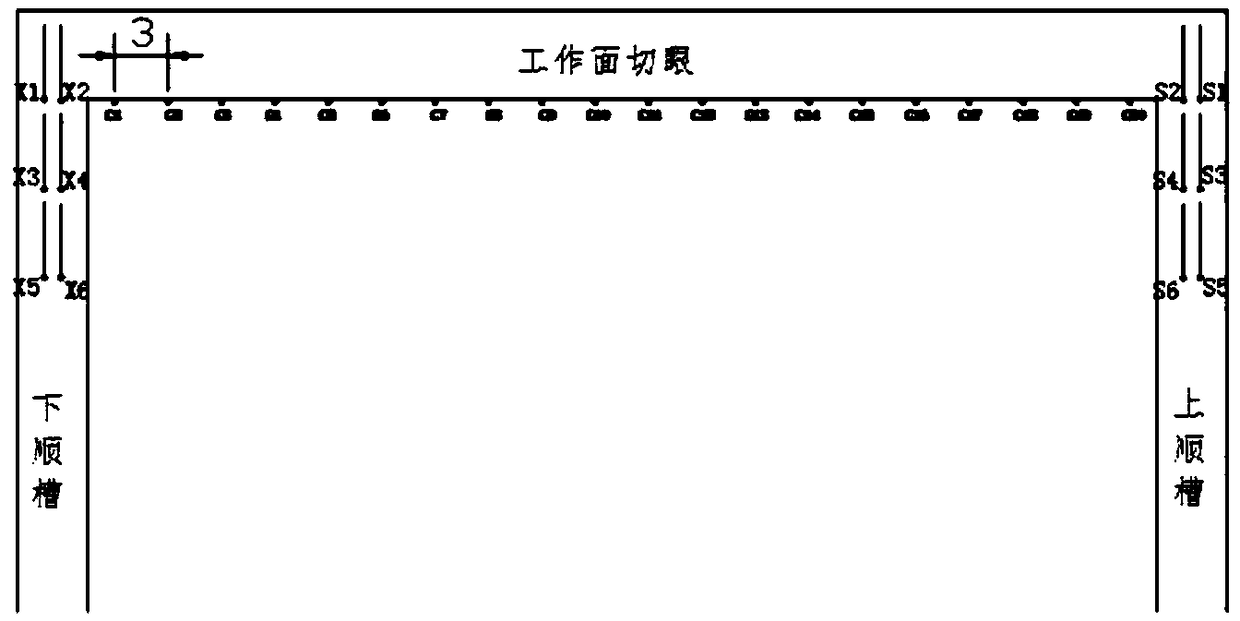

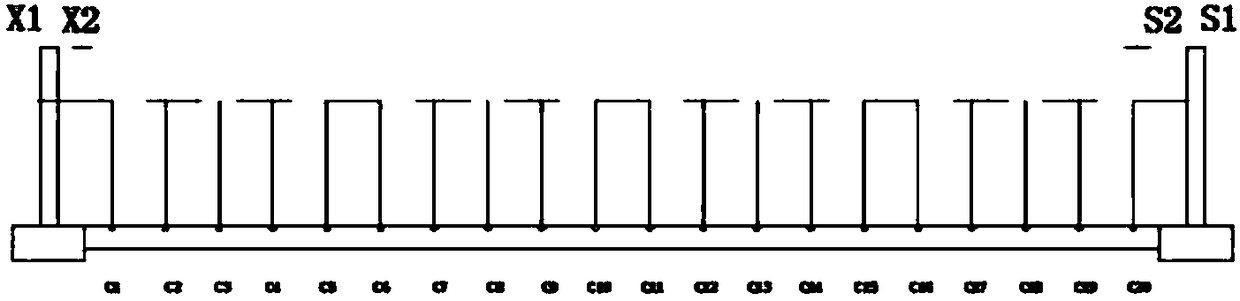

[0024] as attached figure 1 to attach image 3 As shown, the method for multi-point scattered parallel blasthole pre-splitting roof in fully mechanized mining face includes the following steps:

[0025] Step 1: Determine the drilling rig support angle according to the maximum and minimum mining height of the bracket installed in the cutting hole, and determine the blasthole final hole depth, angle, blasthole spacing and number of blastholes according to the roof lithology;

[0026] Step 2: Drilling blastholes in the cutting hole of the coal mining face, the distance between the blastholes is set between the mining side coal wall and the coal wall of the working face, and the blastholes are inclined to the roof of the working face and parallel to the working face. Blast holes are evenly drilled at equal intervals along the cutting direction of the working face;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com