Rock burst prevention and control method of three-dimensional coal pillar coal compressing area

A technology of rock burst and coal pillar, which is applied in drilling equipment and methods, ground mining, earth-moving drilling, etc., can solve the problems of high rock burst risk, prevention and control effect, and high-energy rock burst danger, etc. To achieve the effect of reducing the risk of impact and achieving control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

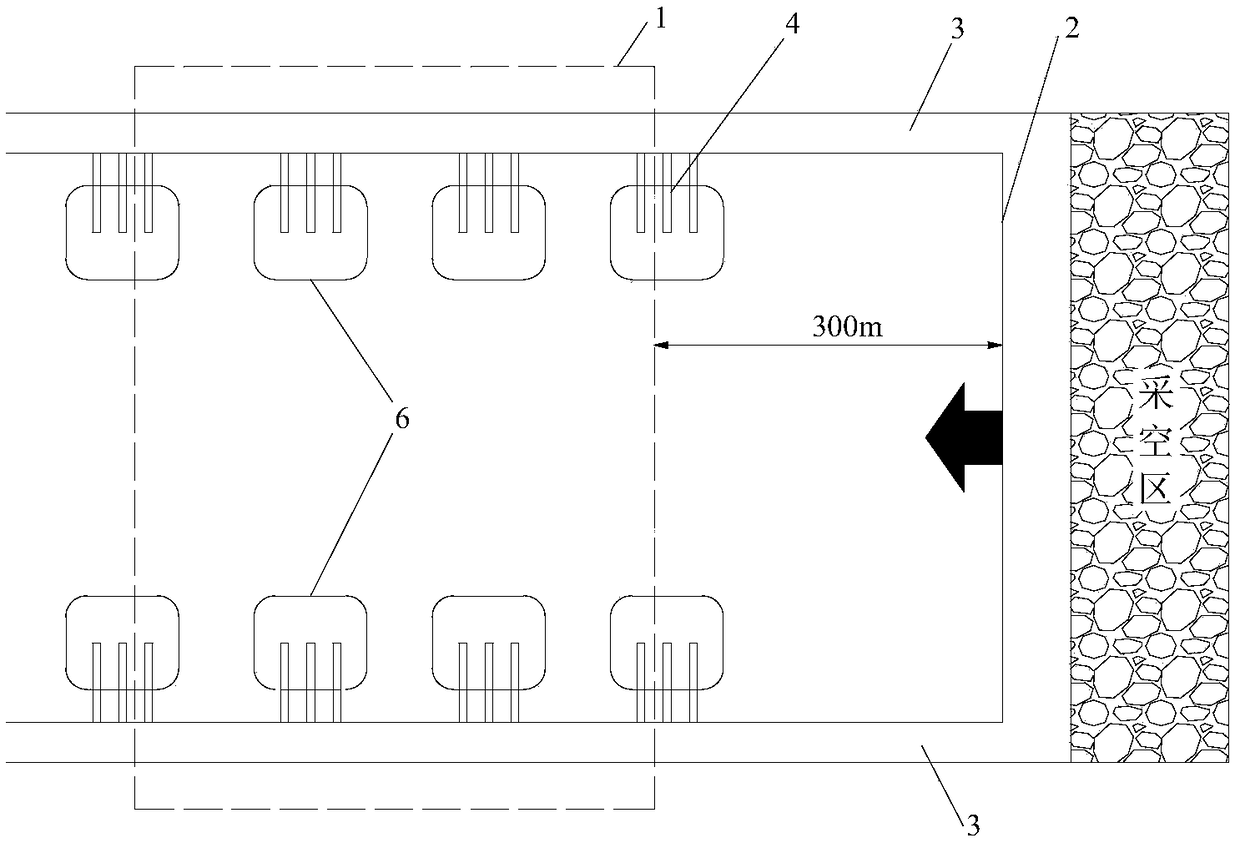

[0028] Such as figure 1 As shown, this embodiment provides a method for preventing and controlling rock burst in a three-dimensional coal pillar coal pressing area, including the following steps:

[0029] Step 1: Determine the coal pressure area of the upper three-dimensional residual coal pillar in the mining face of the coal seam and the influence range of the coal pillar stress, and delineate the impact risk area 1 affected by the three-dimensional coal pillar;

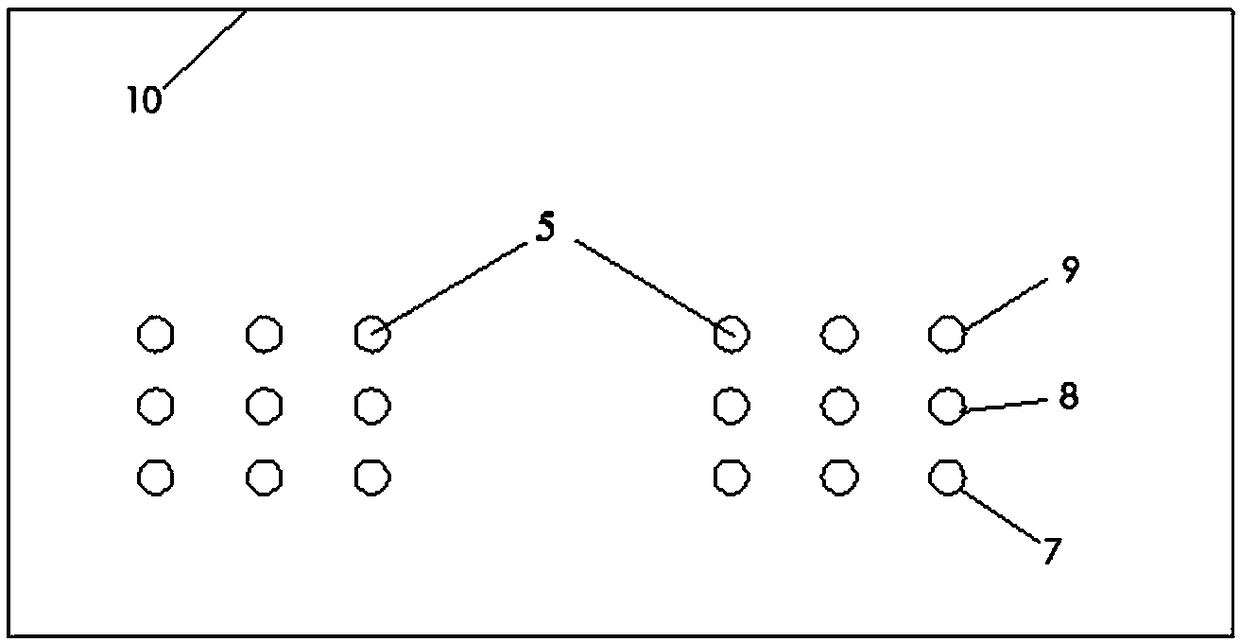

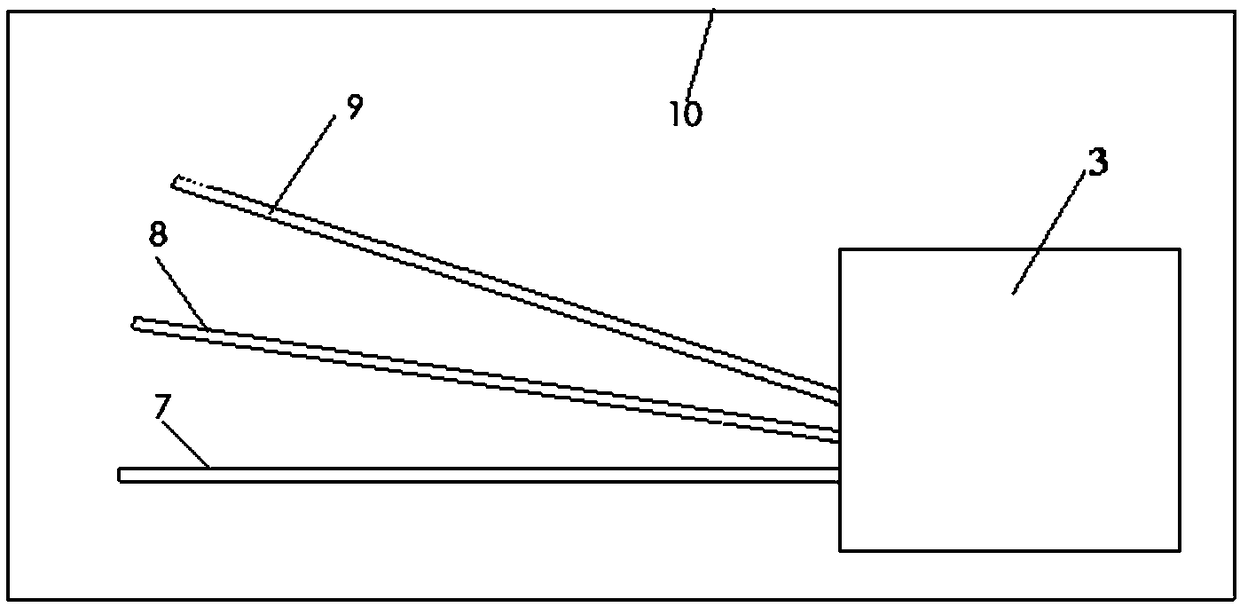

[0030] Step 2: 300m away from the impact dangerous area in front of the coal wall 2 of the working face, within the delineated impact dangerous area 1, a plurality of blasting drilling groups 4 are arranged at intervals on the coal wall 2 of the working face for the roadway 3, each The blasting drill hole group 4 includes a plurality of blasting drill holes 5;

[0031] The third step: fill the depth of the blasting borehole 5 with explosives, seal the remaining length of the blasting borehole 5 with gun mud, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com