Method for controlling tectonic rock burst in coal mine tunneling

A technology of rock burst and coal mine roadway, which is applied in ground mining, mining equipment, earthwork drilling and mining, etc., to prevent structural stress, increase the thickness of rock strata, and reduce the risk of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is specifically implemented as follows:

[0020] Step 1: During the excavation process of rock burst dangerous coal seams, through analogy, analysis and judgment of roadway rock burst appearance characteristics, and at the same time, according to the structural distribution of excavation, use the actual observation method of in-situ stress to observe the in-situ stress , to obtain the magnitude and direction of the in-situ stress, and then use the drilling cuttings monitoring method to conduct on-site detection, and divide the structural high-stress area as the key area for the prevention and control of structural rock burst;

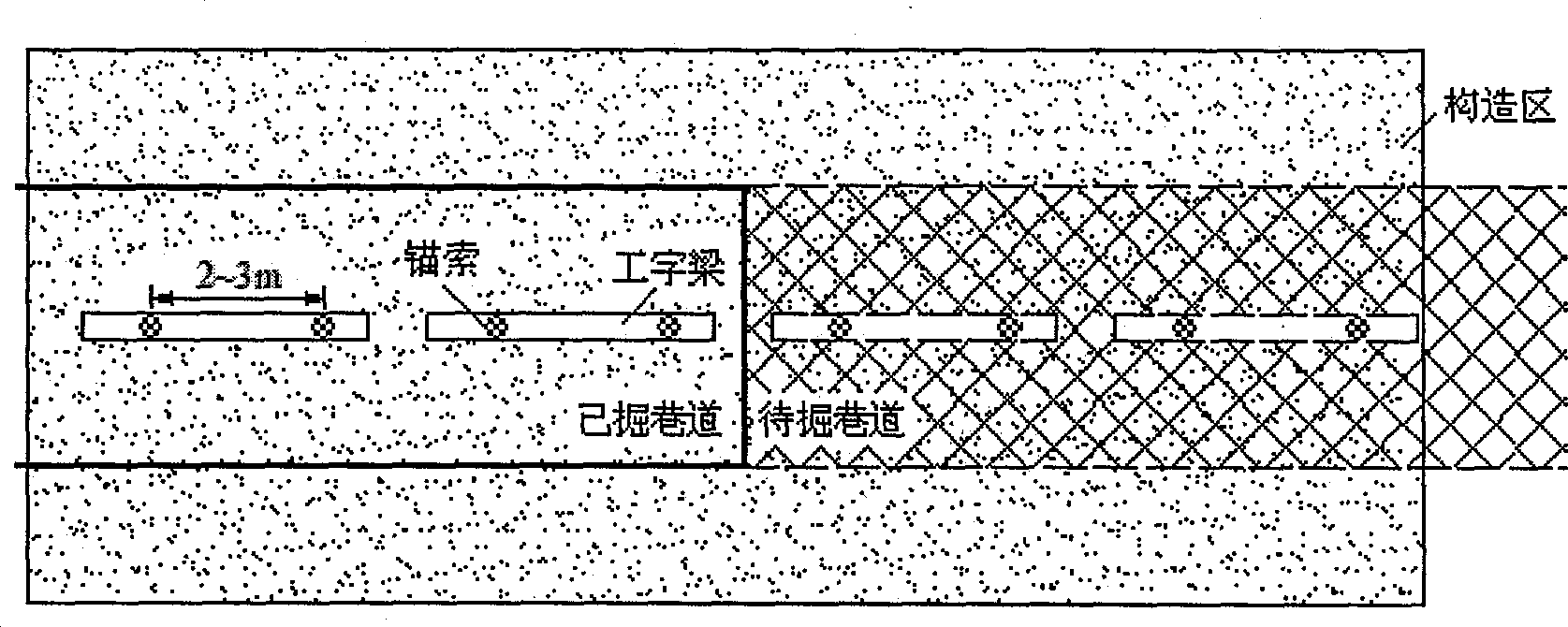

[0021] According to the strength of the stress distribution, delineate the dangerous area, see figure 1 The part shown on the right.

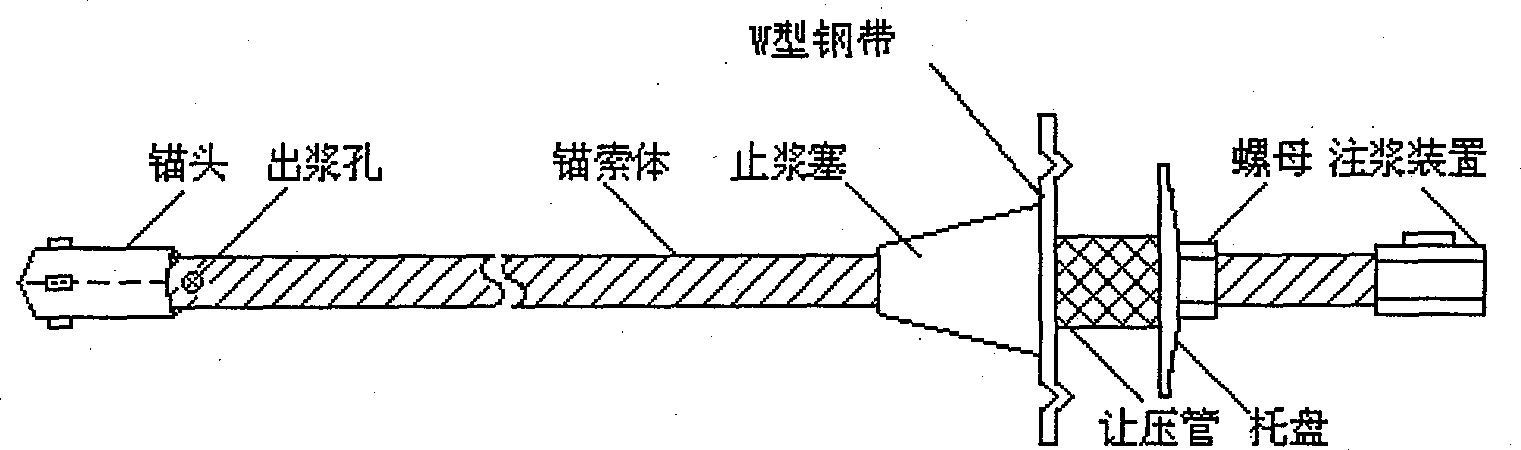

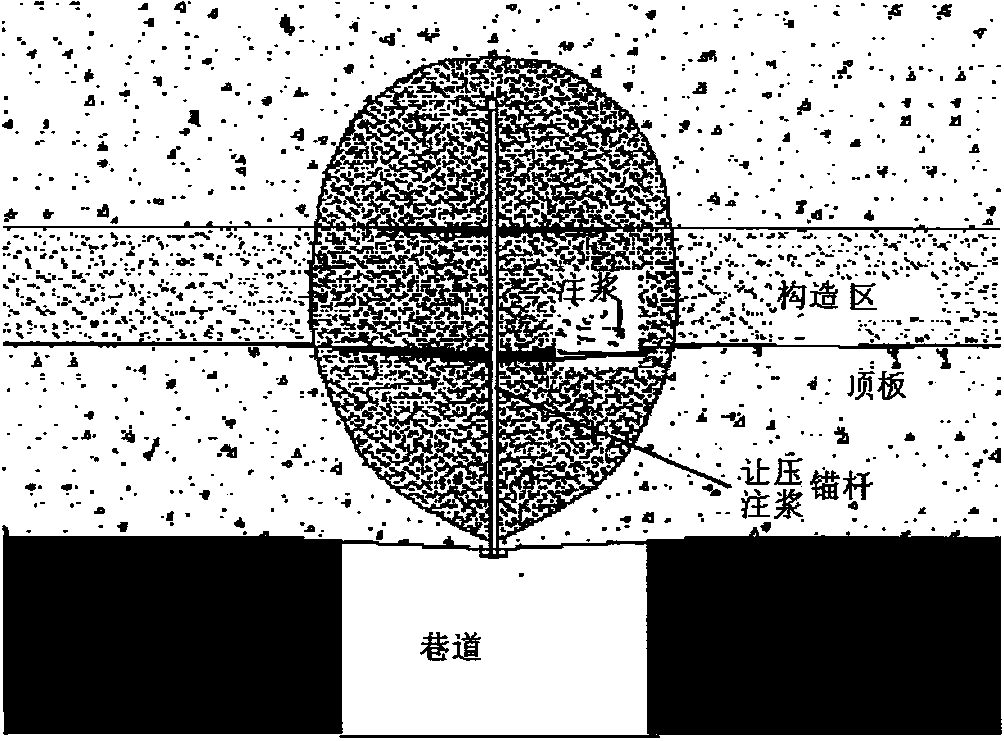

[0022] Step 2: Drill a row of high-strength yielding grouting anchors along the direction of the roadway on the top of the roadway roof that is being excavated in the above-mentioned key pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com