Drilling device for mine engineering blasting

A drilling device and technology for mining engineering, applied in drilling equipment and methods, drilling with explosives, earthwork drilling, etc. Simple, easy to use, easy to move effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

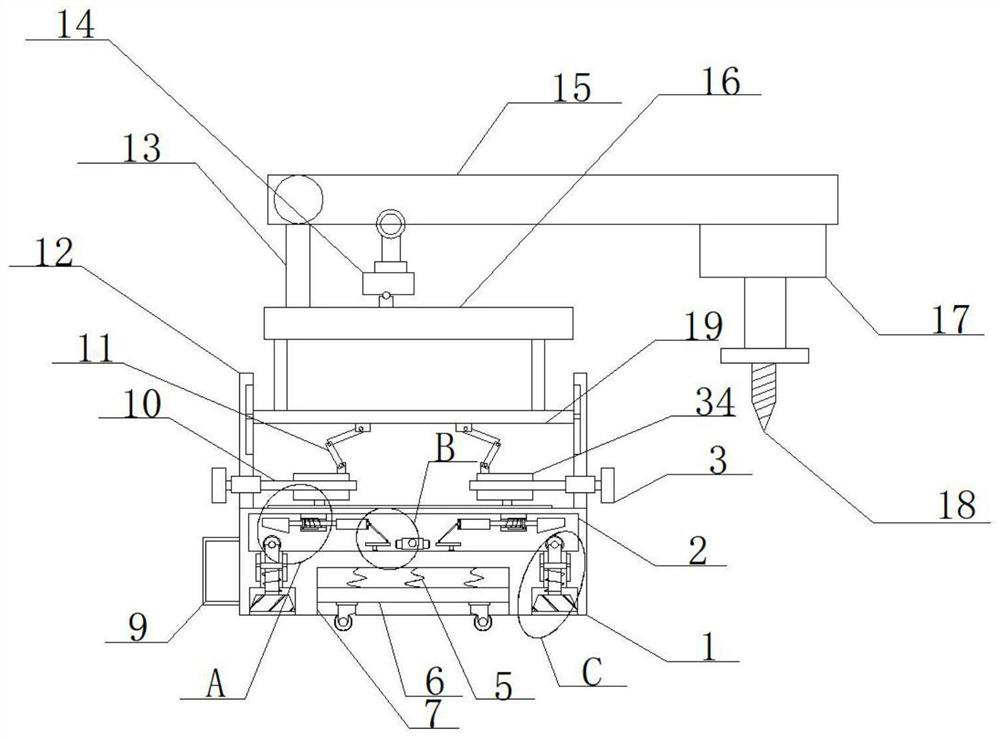

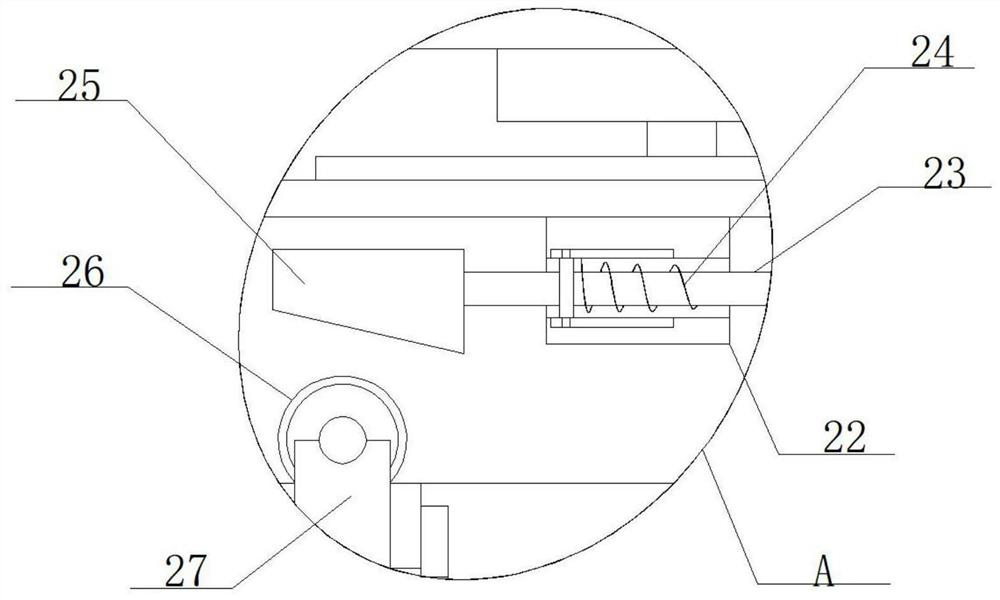

[0025] refer to Figure 1-5 , a drilling device for mine engineering blasting, including a base 1, the bottom of the base 1 is provided with two grooves 4 and an installation groove 7 and a square cavity 2 is opened inside, the installation groove 7 is located between the two grooves 4 and The inside is slidably installed with an engaging plate 6 along the vertical direction, and the four corners of the bottom of the engaging plate 6 are all rotated with universal wheels, and two through holes 8 are provided between the two grooves 4 and the square cavity 2. Vertical rods 27 are installed movably in the through holes 8, rollers 26 are mounted on the tops of the two vertical rods 27 and buffer blocks 33 are fixedly mounted on the bottom ends of the two vertical rods 27, and two plastic blocks are fixedly mounted on the top inner wall of the square cavity 2. 22 and two sector gears 30 are rotated on the bottom inner wall, and two plastic blocks 22 are provided with movable holes...

Embodiment 2

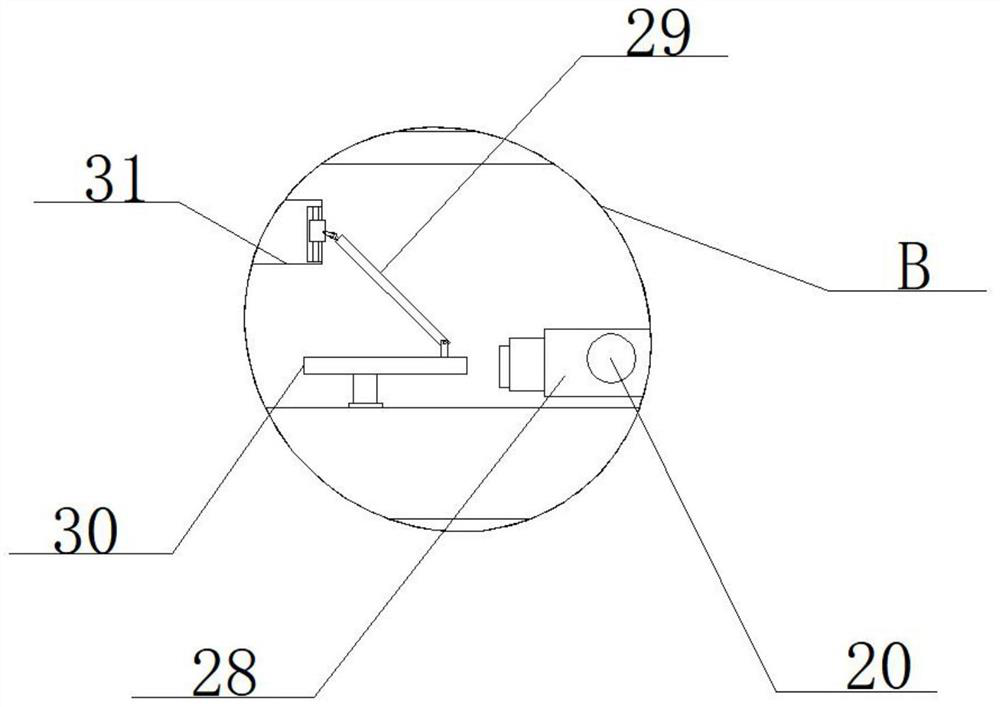

[0027] In the present invention, one side of the base 1 is threaded with a threaded rod 20, one end of the threaded rod 20 is rotatably mounted with a double-sided rack 28 located between two sector gears 30, and the other end is fixedly sleeved with a crank handle 21. Two double-sided racks 28 are all meshed with the sector gear 30, and the inward rotation of the threaded rod 20 is driven by turning the handle 21, which can drive the inward movement of the double-sided rack 28, and the double-sided rack 28 drives the The rotation of the two sector gears 30 can drive the rotation of the two connecting rods 29 , that is, the extrusion can drive the left and right separate movement of the two connecting blocks 31 .

[0028] In the present invention, multiple groups of buffer springs 5 are fixedly installed between the connecting plate 6 and the top inner wall of the installation groove 7, and the multiple groups of buffer springs 5 can play a shock-absorbing and buffering eff...

Embodiment 3

[0035] refer to Figure 1-5, a drilling device for mine engineering blasting, including a base 1, the bottom of the base 1 is provided with two grooves 4 and an installation groove 7 and a square cavity 2 is opened inside, the installation groove 7 is located between the two grooves 4 and An engaging plate 6 is slidably installed inside along the vertical direction, and universal wheels are mounted on the four corners of the bottom of the engaging plate 6 through bearings, and two through holes 8 are opened between the two grooves 4 and the square cavity 2, Both vertical rods 27 are movably installed in the two through holes 8, and the tops of the two vertical rods 27 are installed with rollers 26 and the bottom ends are fixedly welded with buffer blocks 33 by bearing rotation, and the top inner wall of the square cavity 2 is fixedly welded with Two plastic blocks 22 and two sector gears 30 are mounted on the inner wall of the bottom by bearing rotation, two plastic blocks 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com