Repeated dry ice cracking rock breaking orifice clamping device and using method thereof

A locking device and a technology for breaking rock holes, which are applied in drilling equipment and methods, drilling and blasting using explosives, etc., can solve problems such as injury to construction site workers, buildings, loss of people and things, and improve safety. , reduce cost, reduce the effect of punching phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

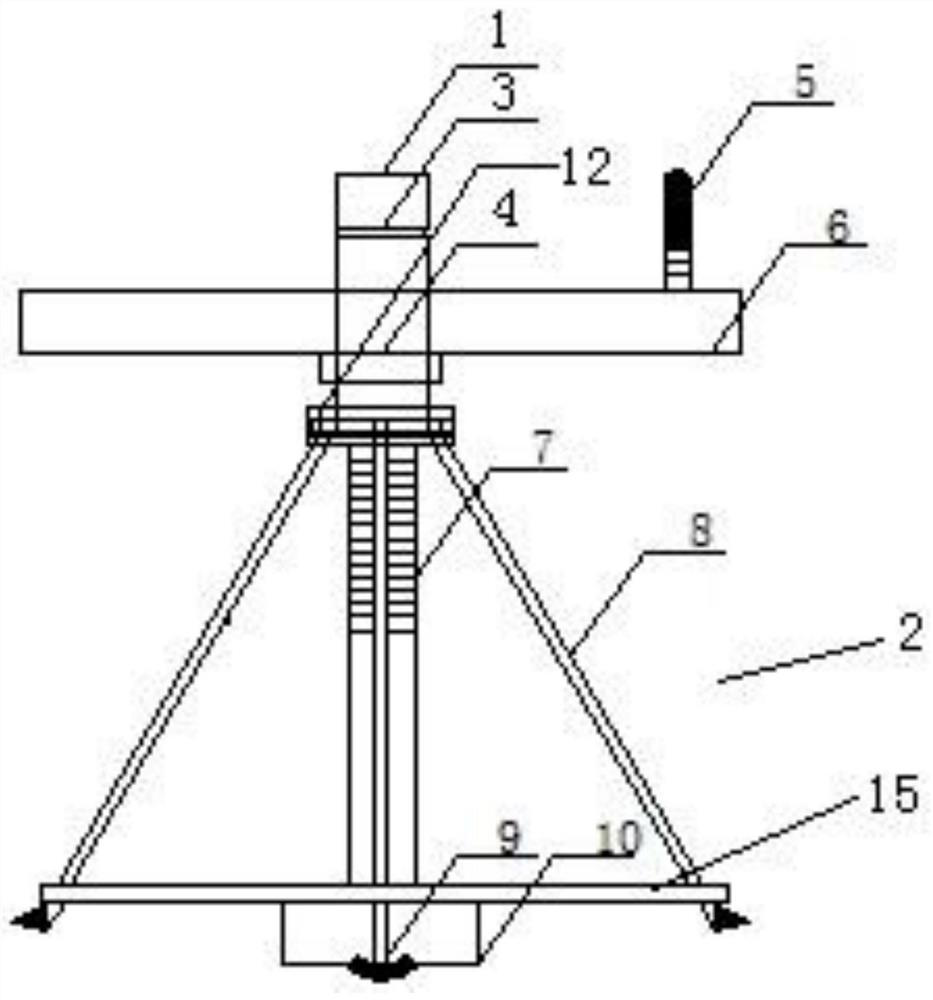

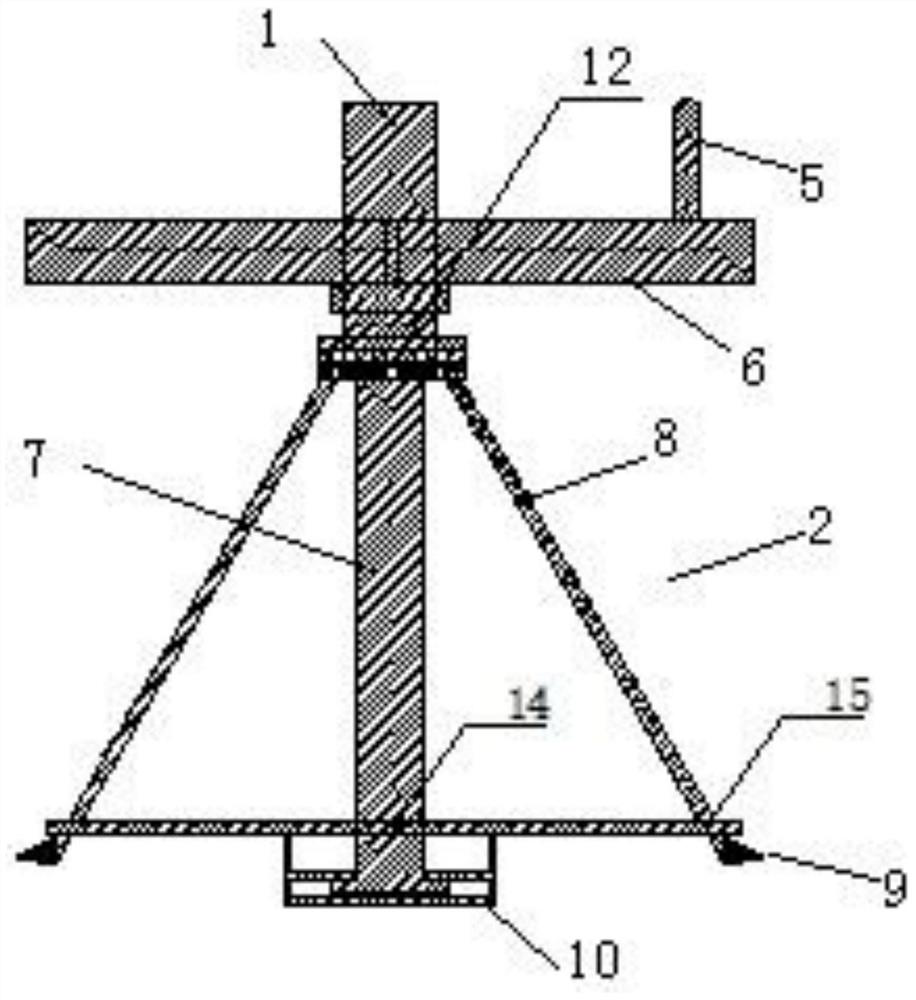

[0037] Such as Figure 1~Figure 3 As shown, a repetitive dry ice fracturing rock breaking orifice clamping device includes a clamping device body 2, and the clamping device body 2 includes a half-threaded column 7 with threads in the upper half.

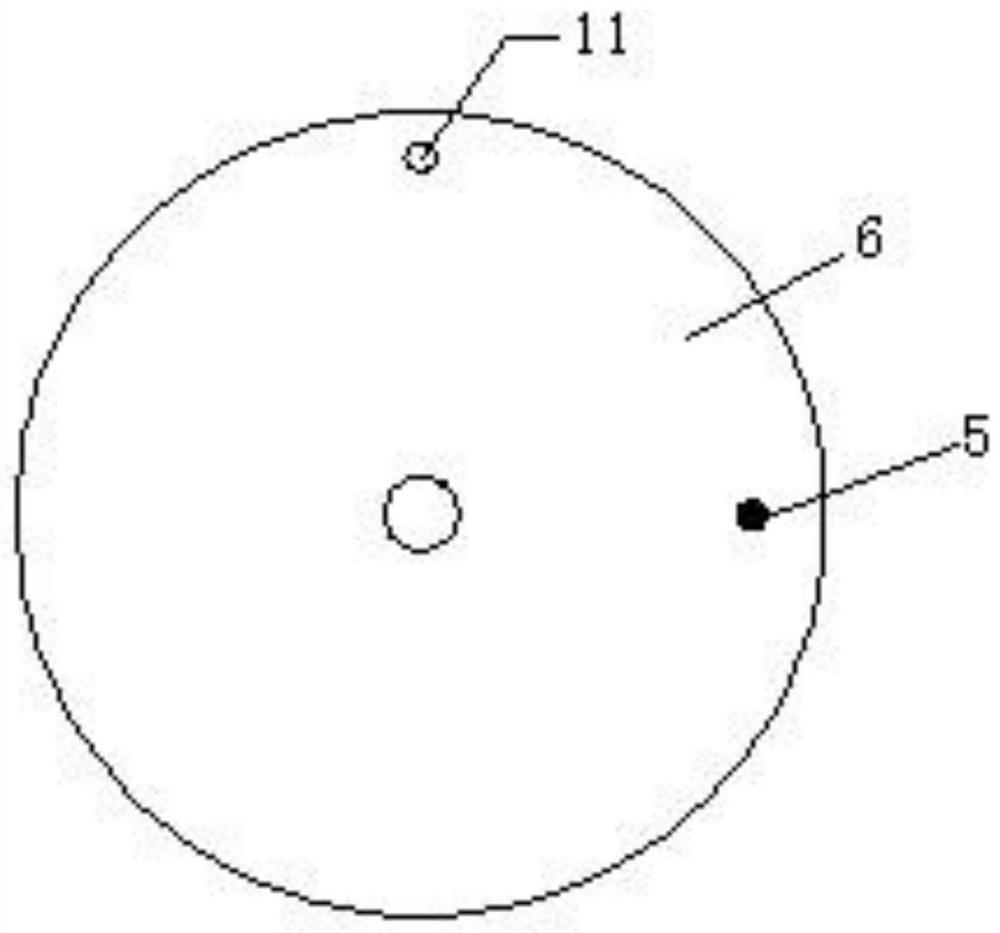

[0038] The top end of the half-threaded column 7 is provided with an upper terminal 1 , and an annular groove 3 is provided on the side wall of the upper terminal 1 . The upper end 1 plays the role of limiting the sleeve 4, preventing the sleeve 4 from unscrewing the half-threaded column 7, and the upper end 1 can also play the role of fixing the half-threaded column 7. When the turntable 6 is rotated, the half-threaded column is avoided. 7 rotates thereupon. The annular groove 3 is used for binding the wire rope 105 .

[0039] The bottom end of the half threaded column 7 is provided with a lower movable end 10, which is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com