Drilling and blasting vehicle for tunnel excavation construction integrated with rotating and translation functions

A technology of tunnel excavation and integration, which is applied in the direction of tunnels, drilling with explosives, and drilling equipment. It can solve the problems of long time consumption, large manpower and material resources, and affecting the tunnel construction period, so as to achieve convenient movement, save construction time, The effect of high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

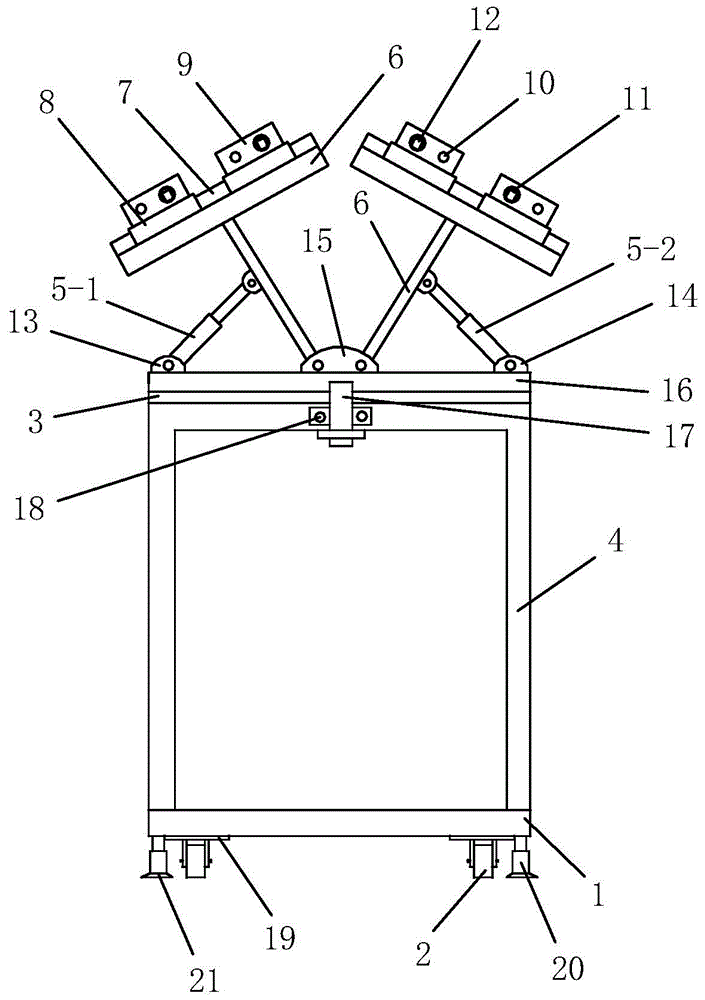

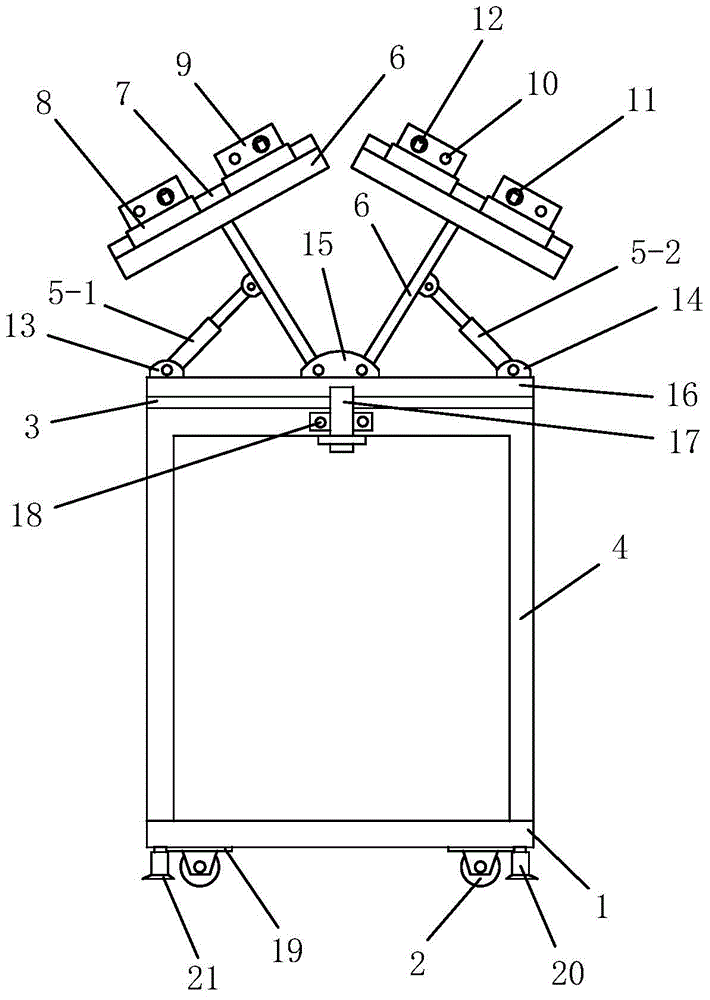

[0024] Such as figure 1 , figure 2 As shown, the present invention includes a section steel chassis 1 welded by a plurality of section steel rods and arranged horizontally, a vertical vehicle frame 4 installed on the section steel chassis 1, and a horizontal slide plate 3 installed on the vertical vehicle frame 4 , the horizontal turntable 16 that is installed on the horizontal slide plate 3, two hydraulic cylinders that are all installed on the horizontal turntable 16 and two swinging rock drilling blasting mechanisms that are all installed on the horizontal turntable 16. The two hydraulic cylinders are respectively the left side hydraulic cylinder 5-1 on the left side above the vertical vehicle frame 4 and the right side hydraulic cylinder 5-2 on the right side above the vertical vehicle frame 4, and the two swing type The rock-drilling and blasting mechanisms are respectively a swing-type rock-drilling and blasting mechanism 1 driven by the left hydraulic cylinder 5-1 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com