Well-drilling redressing and reaming device

A reaming and drilling technology, applied to drilling equipment, drill bits, earthwork drilling and production, etc., can solve the problems of large reaming torque, long reaming time, high risk of drilling tools, etc., and achieve strong lateral force bearing capacity and cutting effect Obvious, avoid the effect of eating into the formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

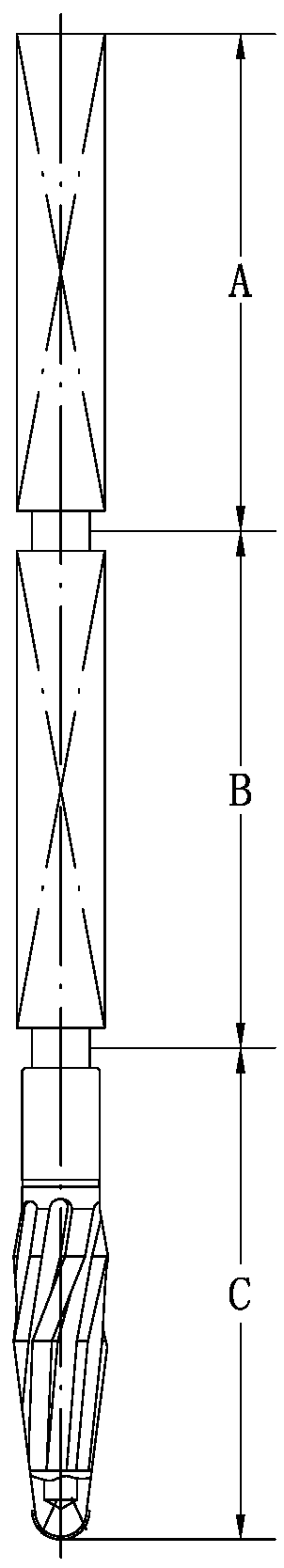

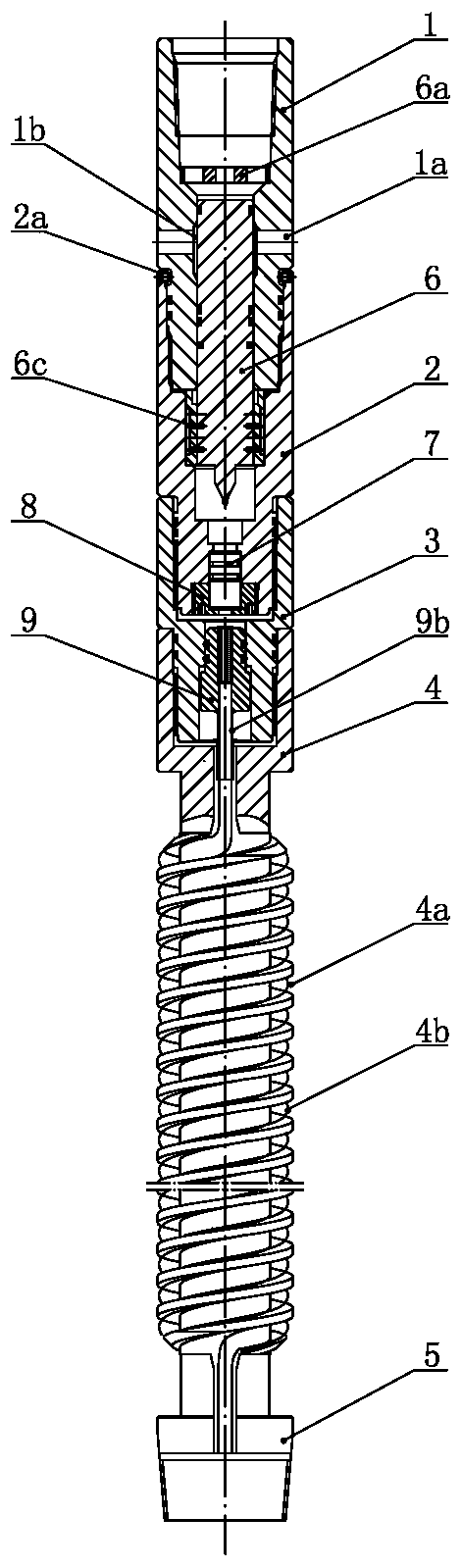

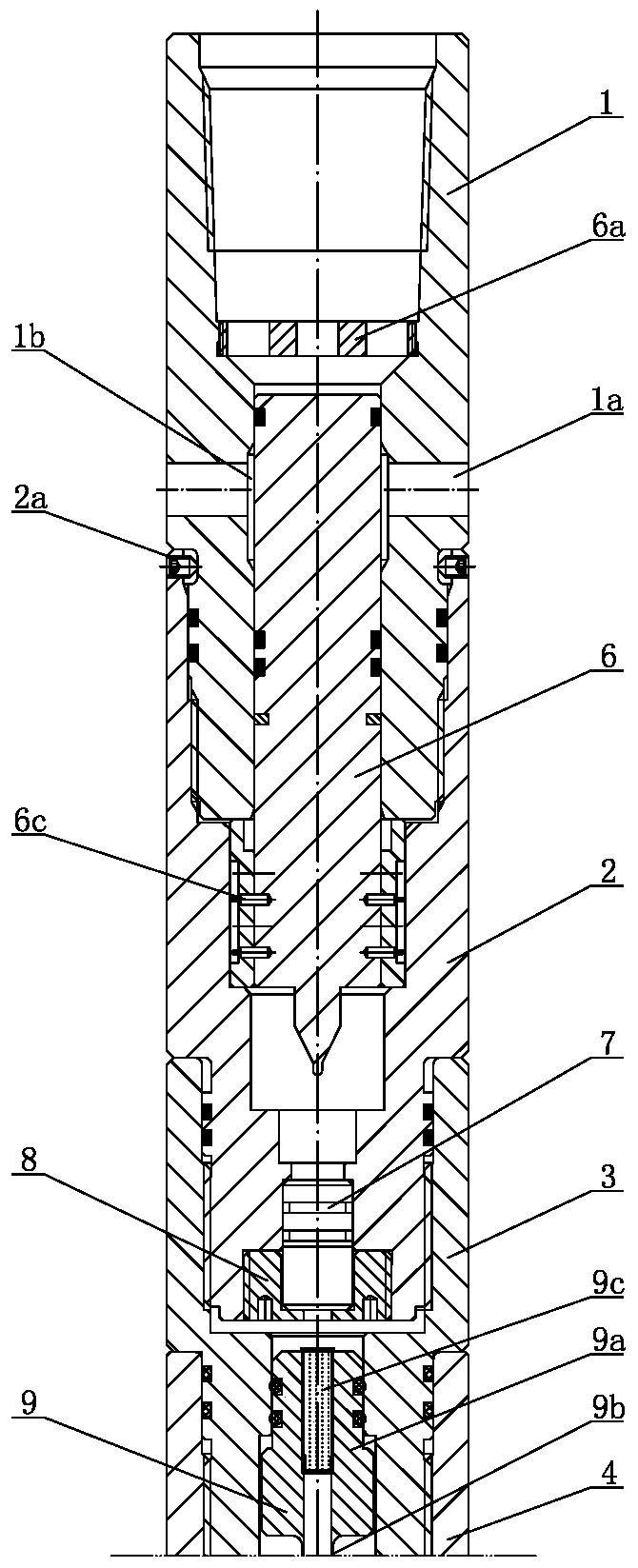

[0035] Such as figure 1 As shown, the drilling reaming and reaming device of the present invention includes a pilot reamer C located at the lowest end of the drill string, an explosive reamer B is connected above the pilot reamer C, and an explosive reamer B is connected above the reamer B. It is connected with a variable diameter reamer A. When the drill string is going downhole, firstly, the reamer C reaches the well section to be reamed to remark the wellbore, to ensure the wellbore is round, remove the sundries attached to the wellbore, and make the wellbore unblocked; then The drill string continues to move down and the explosive reamer B reaches the predetermined position. After the explosive reamer B is detonated and reamed, the drill string continues to move down and the variable diameter reamer A reaches the reamed well section, and the well section is reamed. Repairing makes the reaming section round and smooth; in this way, the whole process of reaming, reaming and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com