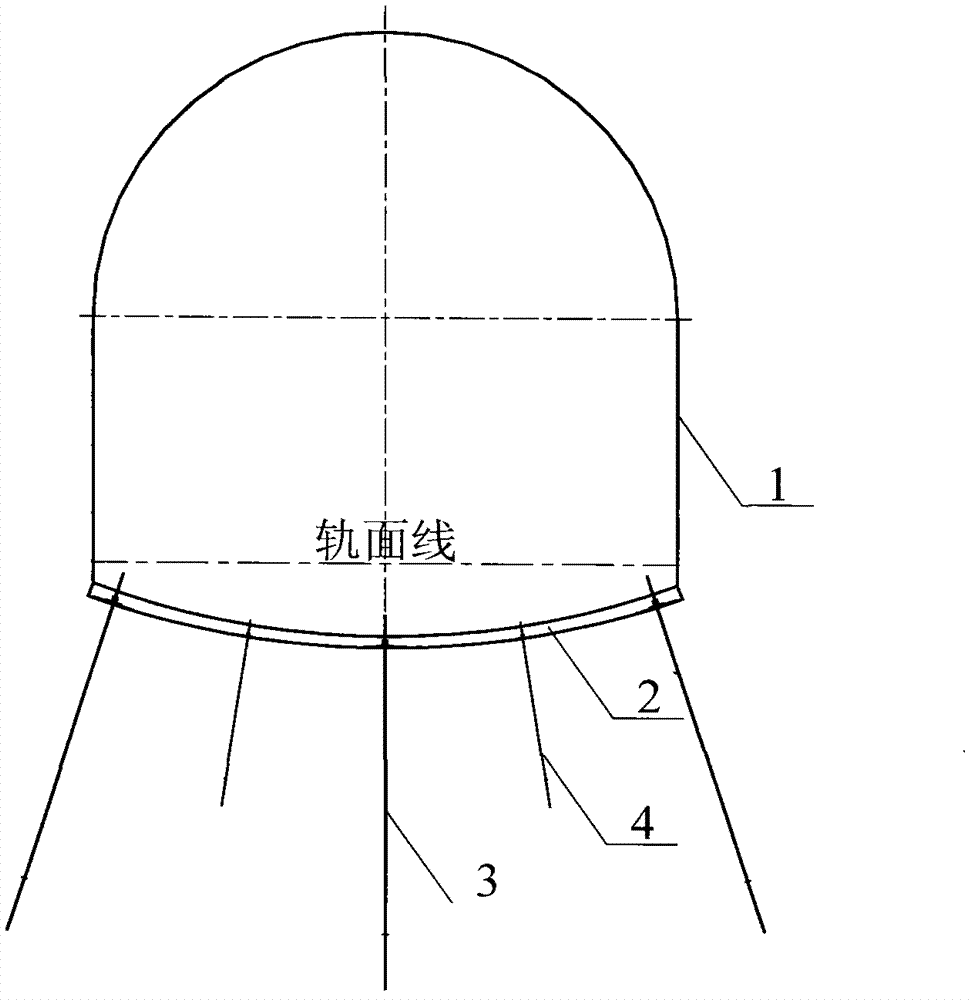

Method for controlling floor heave through inverted arch anchoring beam

A technology of reverse bottom arch and anchoring beam, which is applied in the directions of bolt installation, earthwork drilling, wellbore lining, etc., can solve the problems that the bottom drum, the bottom beam and the anchoring can not be cooperatively carried, and the role of anchoring engineering is not considered, and achieves a large scale. The effect of support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0020] 1. Undercover. The bottom plate of the whole Matoumen area is in reverse arc shape with a radius of 8300mm. Actually, it should be slightly overcut, but the maximum amount of overbreak should not exceed 200mm. When the brush lies within 10m of the north and south sides of the well shaft, the 650mm thick side of the Matou Gate must be protected. After the excavation of the foot of the wall, the formwork must be supported in time, and the reinforced concrete should be poured. The head door design is the same.

[0021] 2. Bottom plate grouting. The depth of the grouting holes on the bottom plate is 2400mm, and each section is arranged with 2 to 3 holes, and the row spacing between the grouting holes is 1300mm×800mm; the grouting pressure is not greater than 1.5MPa; the grouting material is 525 sulphoaluminate rapid hardening cement or chemical For grout, if the water-cement ratio of sulfoaluminate rapid hardening cement is 1:0.8~1 (weight ratio); the length of the grouti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com