Porous parallel-connected grouting method and device for reinforcing roadway weak surrounding rock

A technology for weak surrounding rock and roadway, applied in the field of porous grouting methods and devices, can solve the problems of lack of grouting process control methods, occupation of personnel and equipment, low efficiency, etc., to ensure the grouting support effect, improve speed and effect, the effect of improving the quality of grouting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

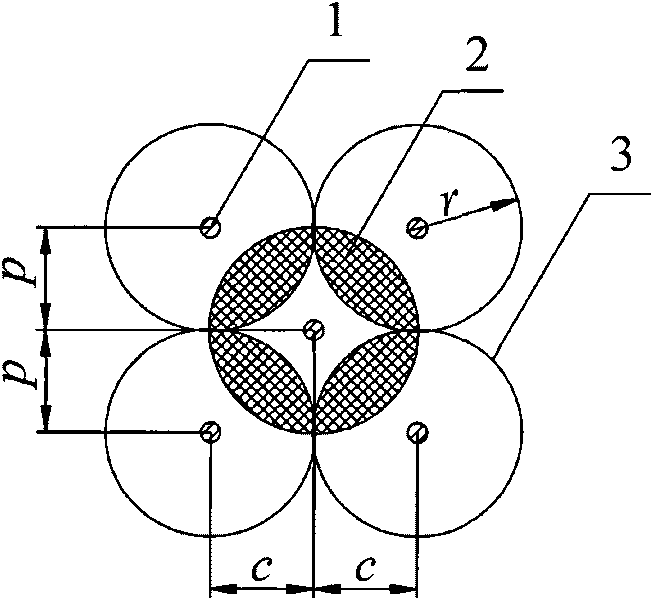

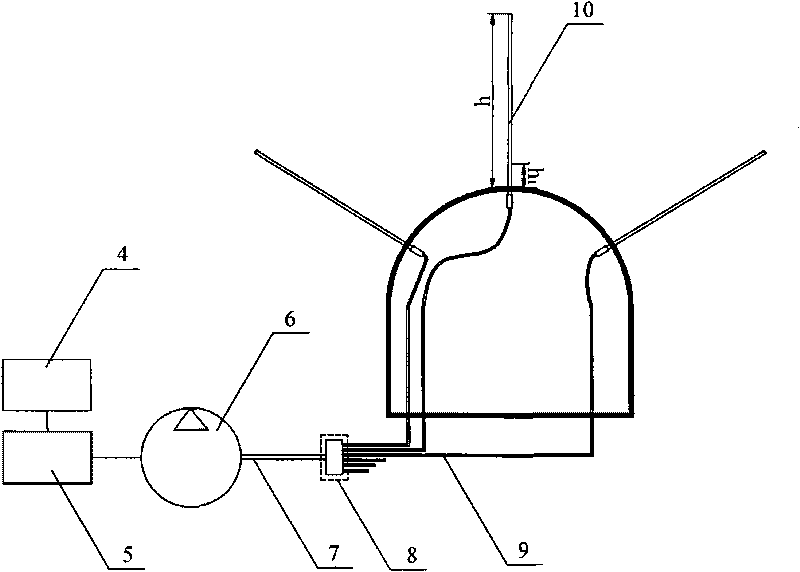

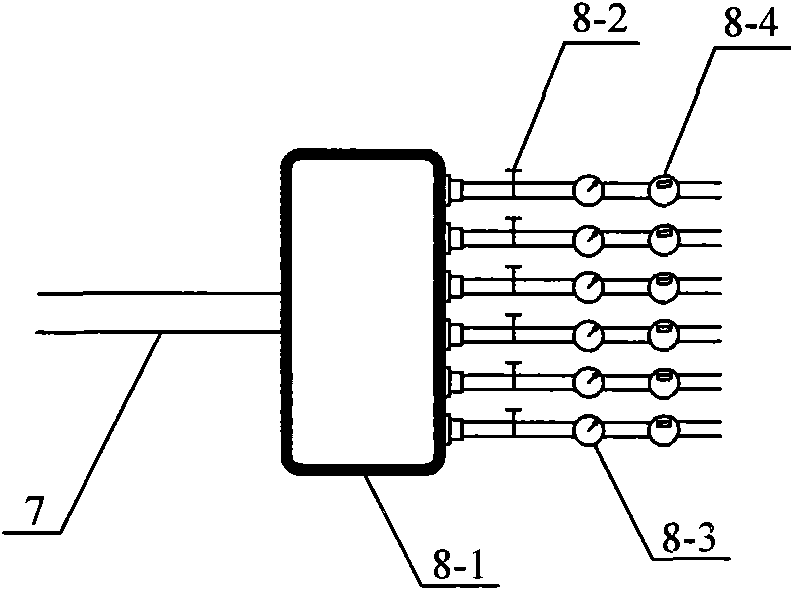

[0018] The multi-hole parallel grouting method of the present invention: firstly, observe and conduct on-site investigation on the damage of surrounding rock and the development of fissures in the construction roadway, and select an area with similar damage degree to arrange the pump station; Or the position of the grouting hole at the top and bottom of the roadway, the position of the grouting hole is determined to satisfy the spacing c of the grouting holes ≤ the diffusion radius r of the slurry, the row spacing of the grouting holes p ≤ the diffusion radius of the slurry r, and the slurry diffusion radius r passes the test The initial field test confirmed that it is about 0.6 ~ 2.0m. The grouting holes 1 are arranged in a plum-shaped hole arrangement, and the spacing and row spacing of the grouting holes should be smaller than the slurry diffusion radius r, so that the slurry diffusion area 3 has an overlapping part 2, such as figure 1 shown. Then carry out a plurality of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com