Suspending movable hydraulic support rack for advanced support in coal cutting roadway

A technology of advanced support and hydraulic support, which is applied in mine roof support, mining equipment, earthwork drilling and mining, etc., and can solve problems such as affecting the passage of personnel and equipment, support cannot be carried out, and support effect is not ideal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with accompanying drawing:

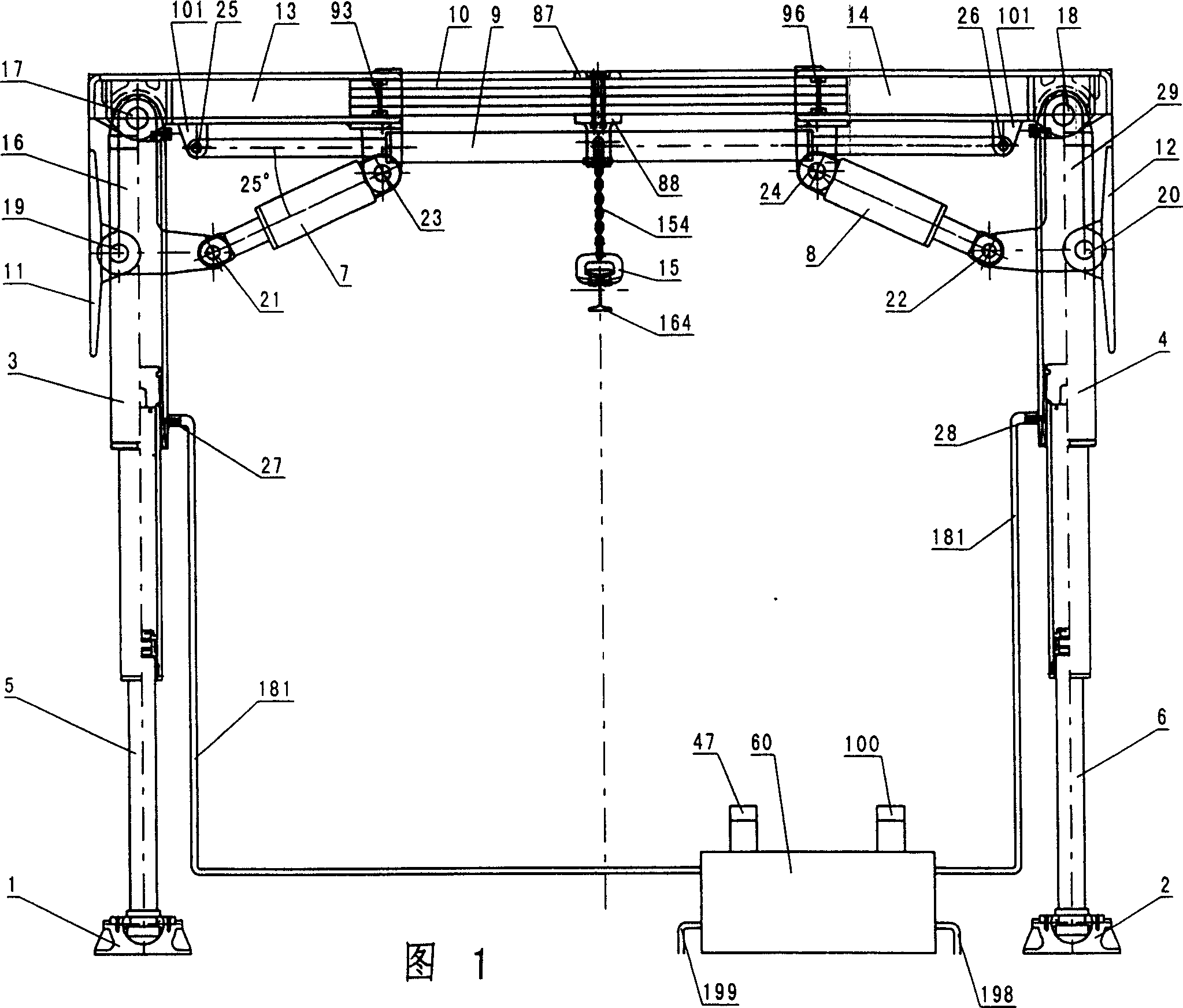

[0054] As shown in Figure 1, it is the support state of the bracket, bottom shoes 1, 2, columns 3, 4, shoulder beams 13, 14, telescopic beams

[0055] As shown in Fig. 1, it is the support state of the bracket. The bottom shoes 1, 2, the columns 3, 4, the shoulder beams 13, 14, and the telescopic beam 9 form an integral portal structure. The telescopic beam oil cylinder 9 is a two-way double-connected transverse expansion, and the cable-stayed oil cylinders 7, 8 pass through the shafts 17, 18, 19, 20, 21, 22, 23, 24 and the columns 3, 4, the telescopic beam 10, and the guard beams 11, 12 , Shoulder girder 13,14, connecting rod 16,29 tractive connection, are the expansion and contraction of control support, the included angle between cable-stayed oil cylinder 7,8 and telescopic beam 10, telescopic beam oil cylinder 9 is 25 ° during support state, is Symmetrical shape; the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com