Roadway support method for fully mechanized caving mining of weak extra-thick coal seam

A technology of extra-thick coal seam and mining roadway, applied in mining equipment, earthwork drilling, installation of bolts, etc., can solve problems such as lack, and achieve the effects of reliable quality, good safety and reasonable parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

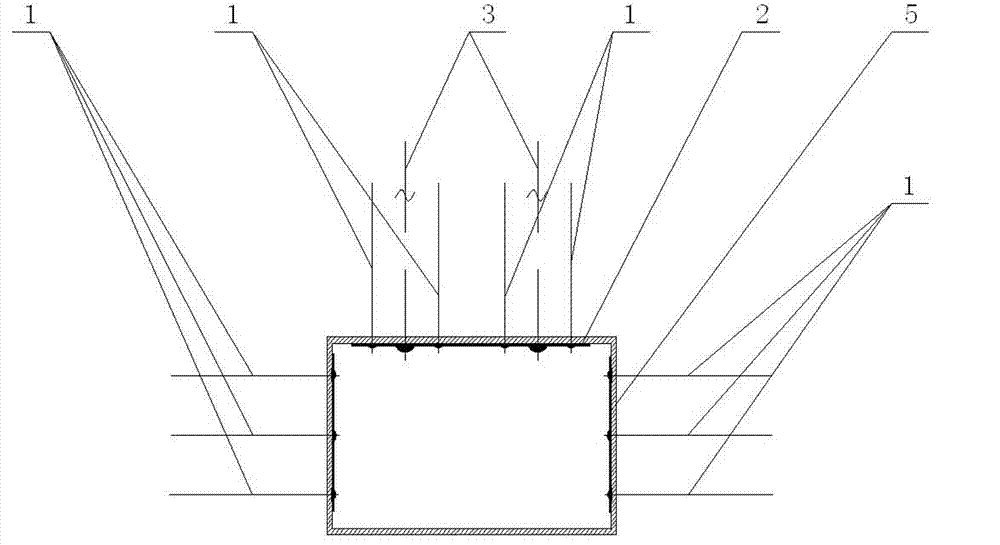

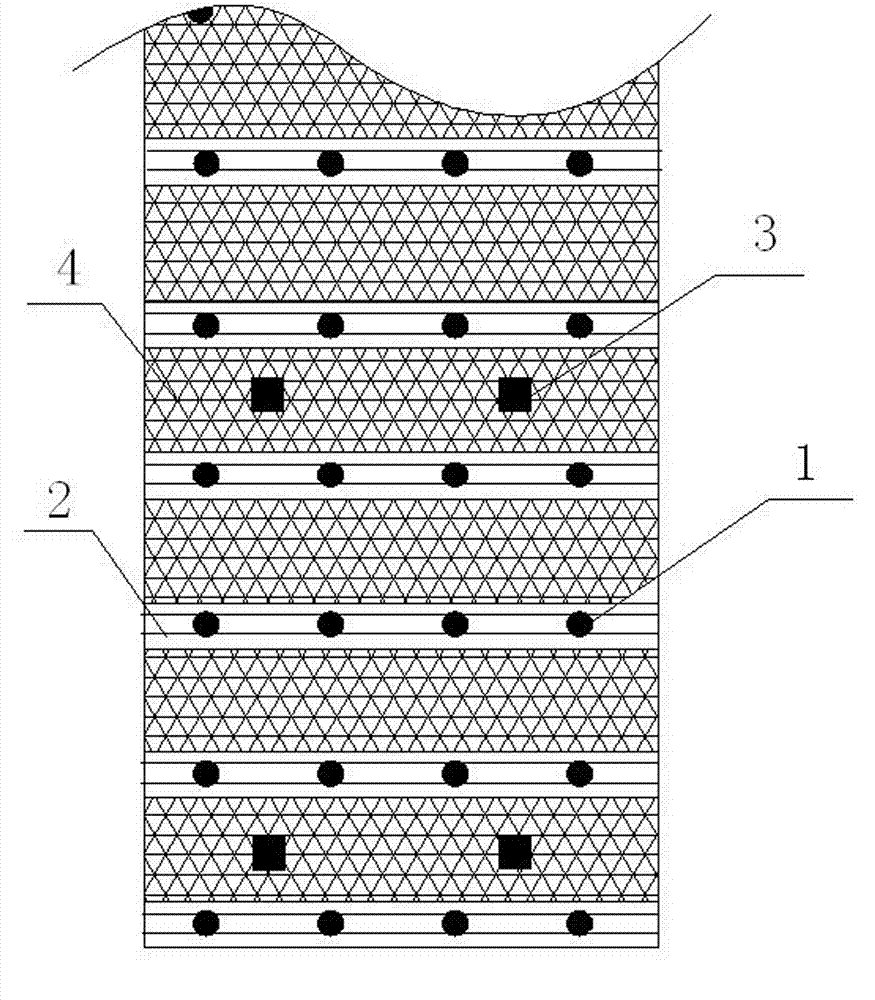

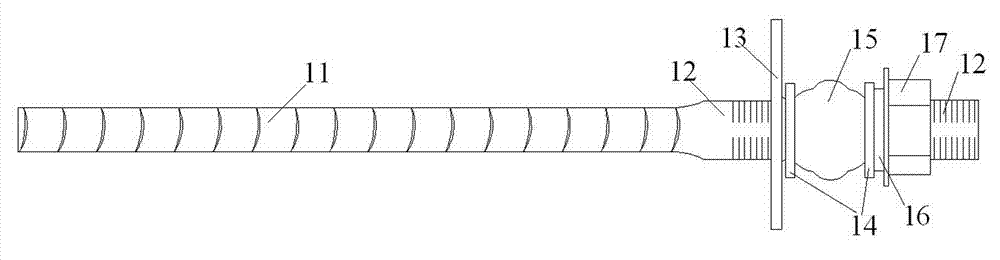

[0011] The method for supporting a roadway in fully mechanized caving back mining in soft and extra-thick coal seams comprises the following steps: fixing a plurality of rows of high-strength metal thick-tail yielding bolts 1 evenly distributed on the roof of the roadway, and every two rows of high-strength metal thick-tailed yielding bolts 1 The distance between them is 1200mm, and there are four high-strength metal thick tail pressure anchor rods 1 in each row, and the distance between every two high-strength metal thick tail pressure anchor rods 1 is 1000mm, and each row of high-strength metal thick tail pressure anchor rods 1 A W-shaped four-eye steel strip 2 is fixed at the lower end of the anchor rod 1. The length of the W-shaped four-eye steel strip 2 is 3200mm, the width is 150mm, and the thickness is 3mm. There is a metal mesh 4 fixed in between, the length of the metal mesh 4 is 3400mm, and the width is 2000mm; the top plate is fixed with several rows of anchor cables...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com