Vertical assembly equipment for shaft assembly of components

A vertical and equipment technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problem that high-pressure rotor vertical intelligent assembly cannot be applied, does not have a large-scale precision attitude adjustment function, and cannot meet five degrees of freedom. motion and other problems, to achieve high-precision positioning function, reduce positioning error, and achieve the effect of precision assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

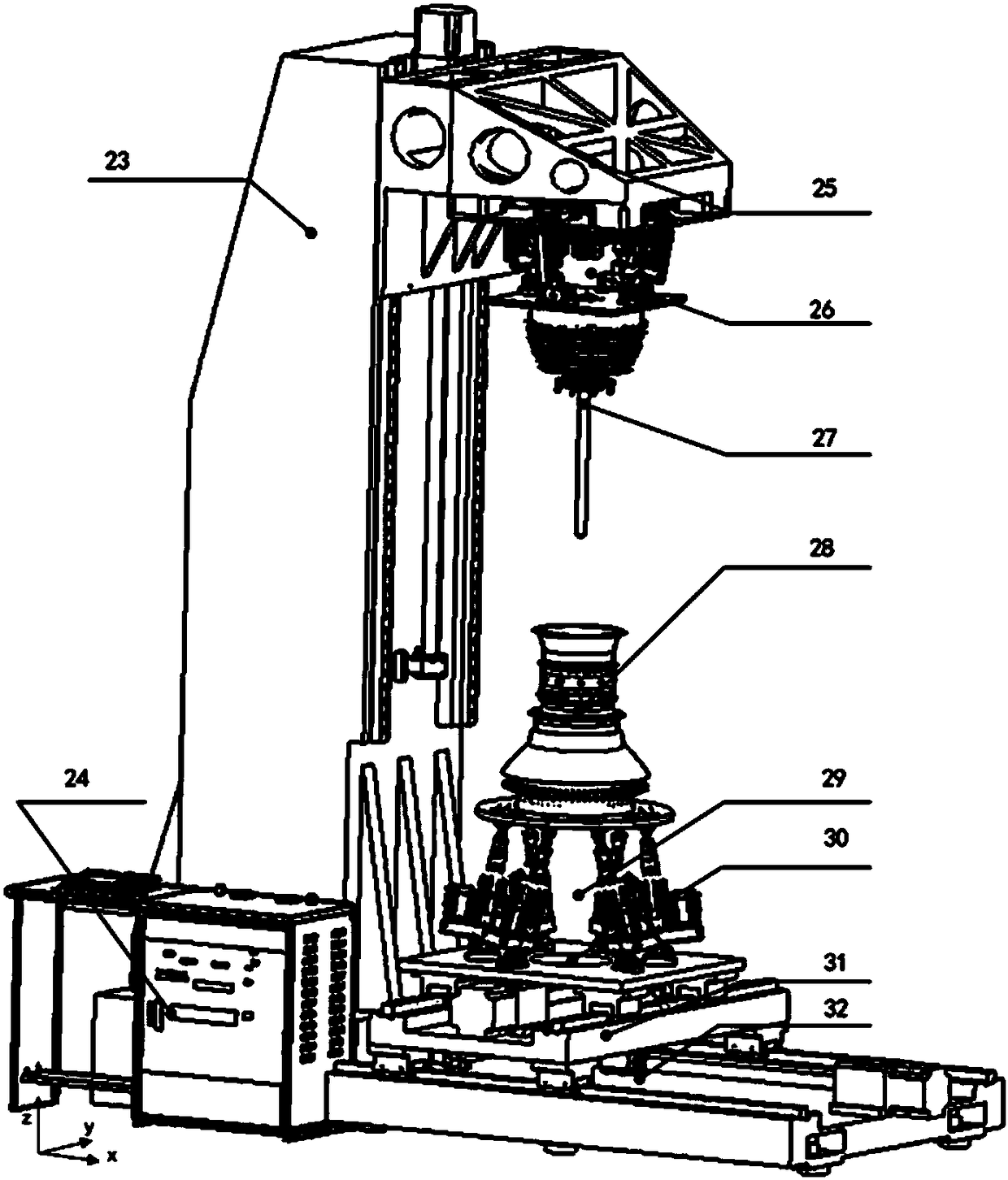

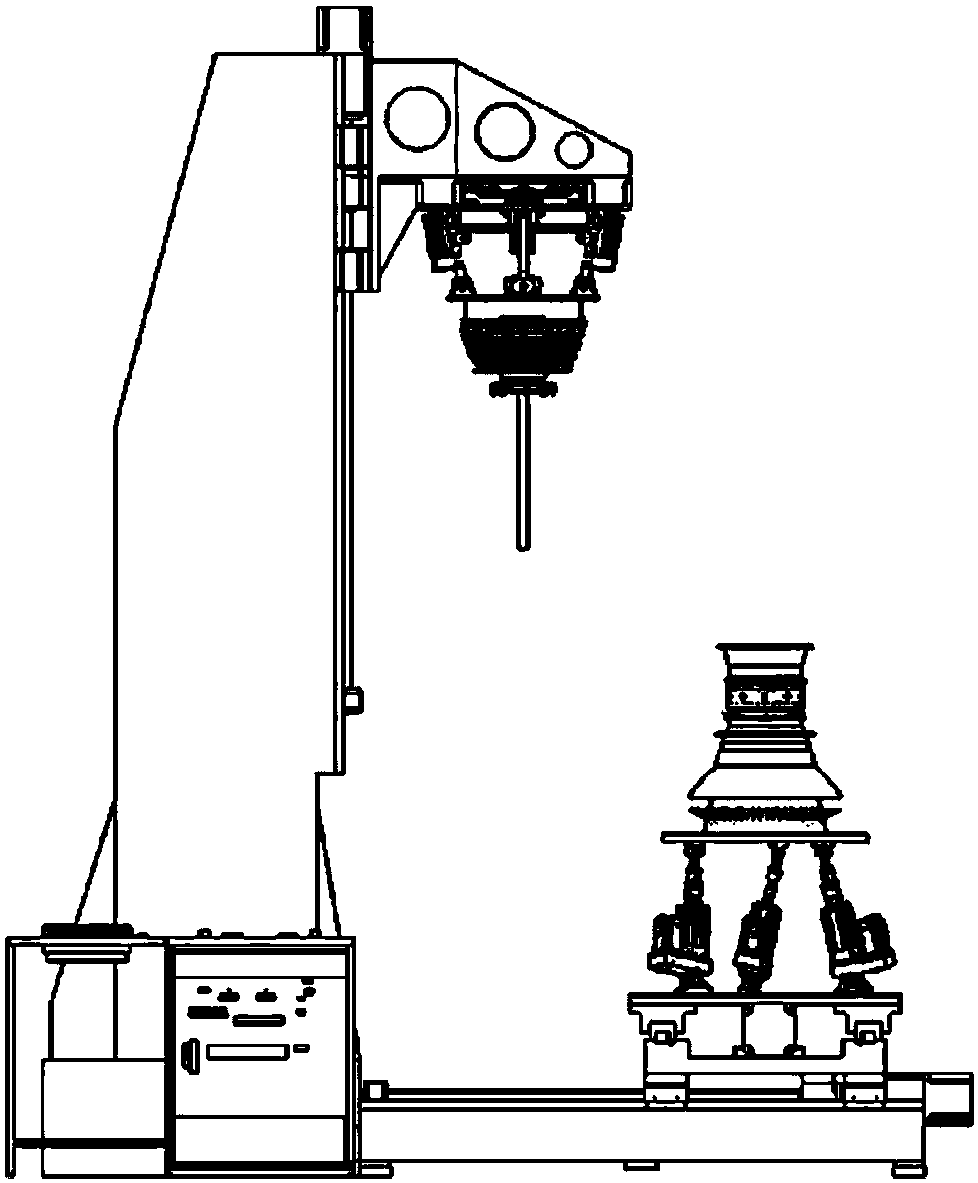

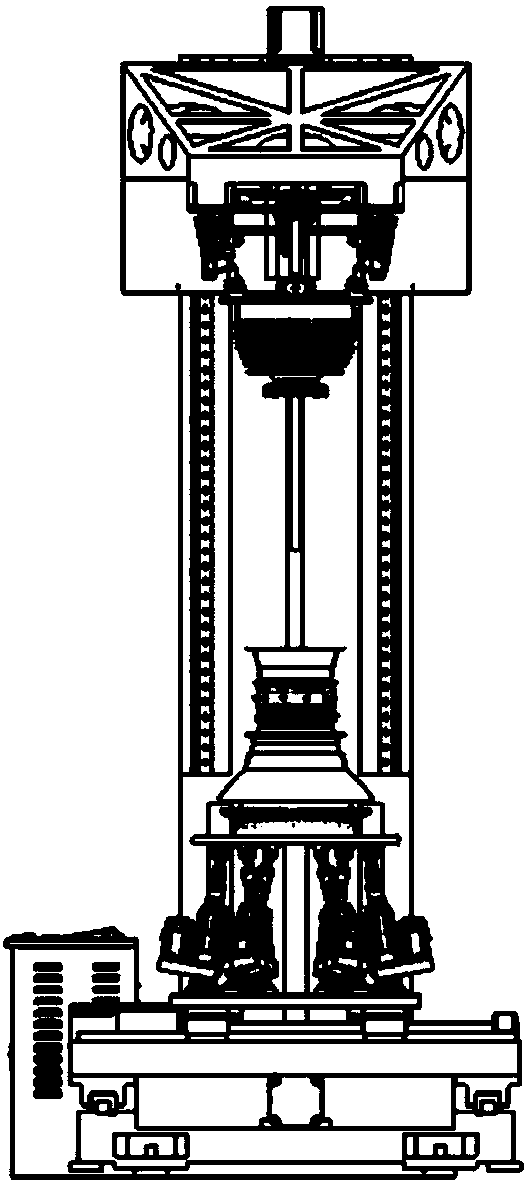

[0024] like Figure 1~3 As shown, in this embodiment, the large-range movement of the hole axis to be assembled is realized by the horizontal and vertical large-range feeding mechanism, and the vertical large-range feeding mechanism includes: vertical column 23 and Z-direction sliding table 25; The range feed mechanism includes: base 32, X-direction slide 31 and Y-direction slide 30, wherein: Z-direction slide 25 is connected with vertical column 23 through screw slide rail, and Y-direction slide 30 is also used for precision adjustment. The six-degree-of-freedom precision attitude adjustment mechanism 29 is connected by a screw slide rail, and the X-direction slide table 31 is connected with the Y-direction slide table 30 by a lead screw slide rail. The passive compliance device 26 and the Z-direction slide table are used to ensure passive safety. 25 is fixedly connected, and the six-degree-of-freedom precision attitude adjustment mechanism 29 is fixedly connected with the Y-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com