Transport mechanism

A transmission mechanism and conveyor belt technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of easily damaged tracks, falling, high energy consumption, etc., and achieve energy consumption reduction, precise positioning, and reduction of switches Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

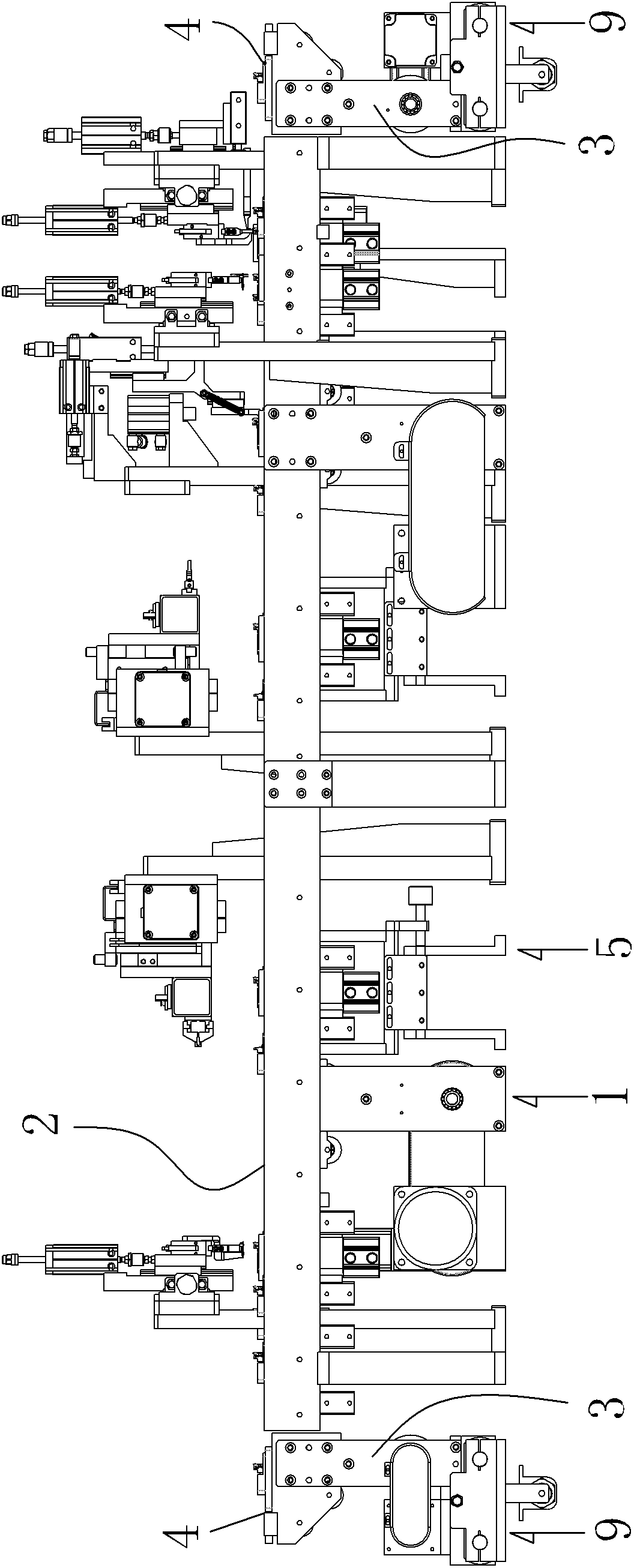

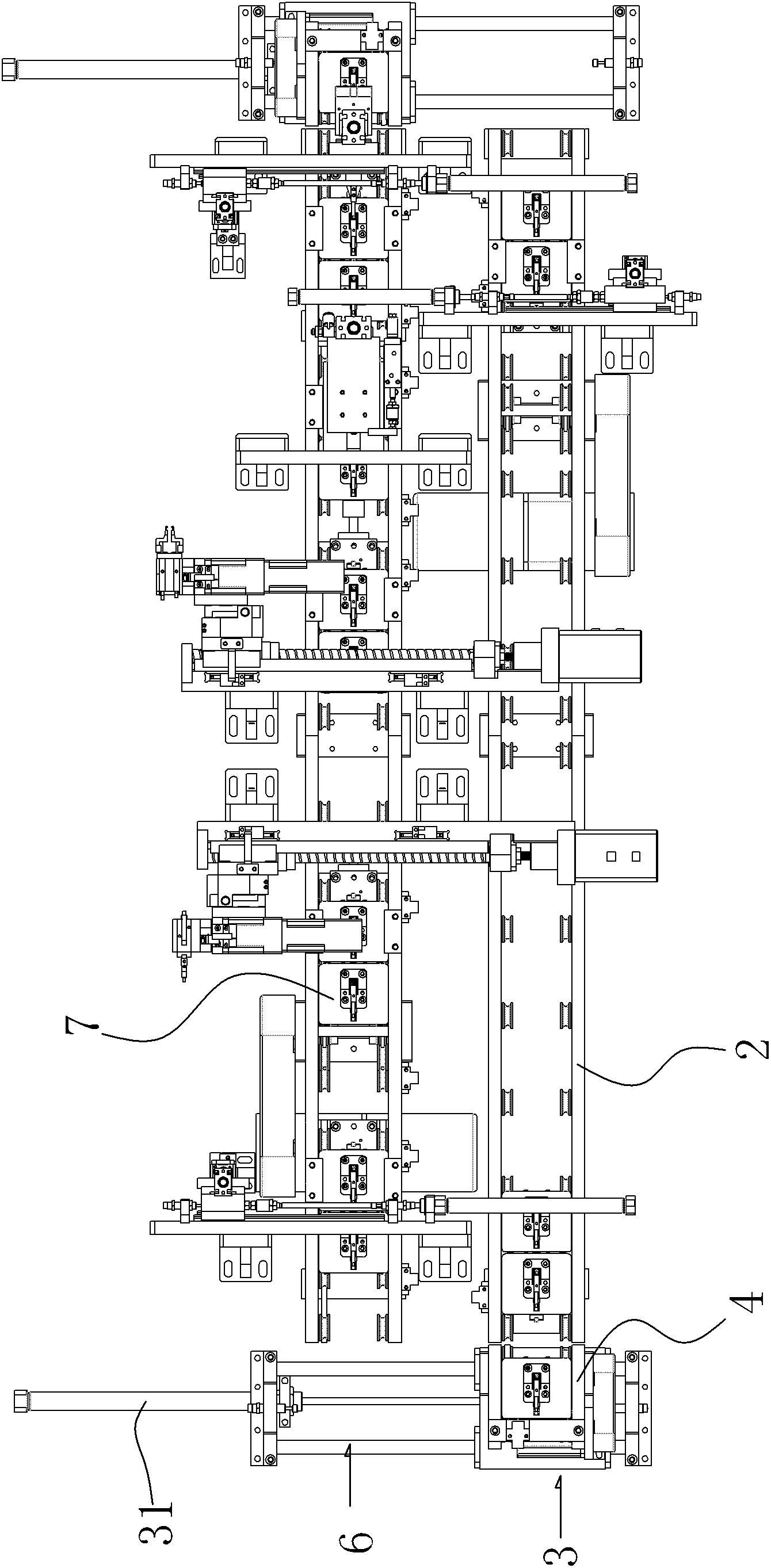

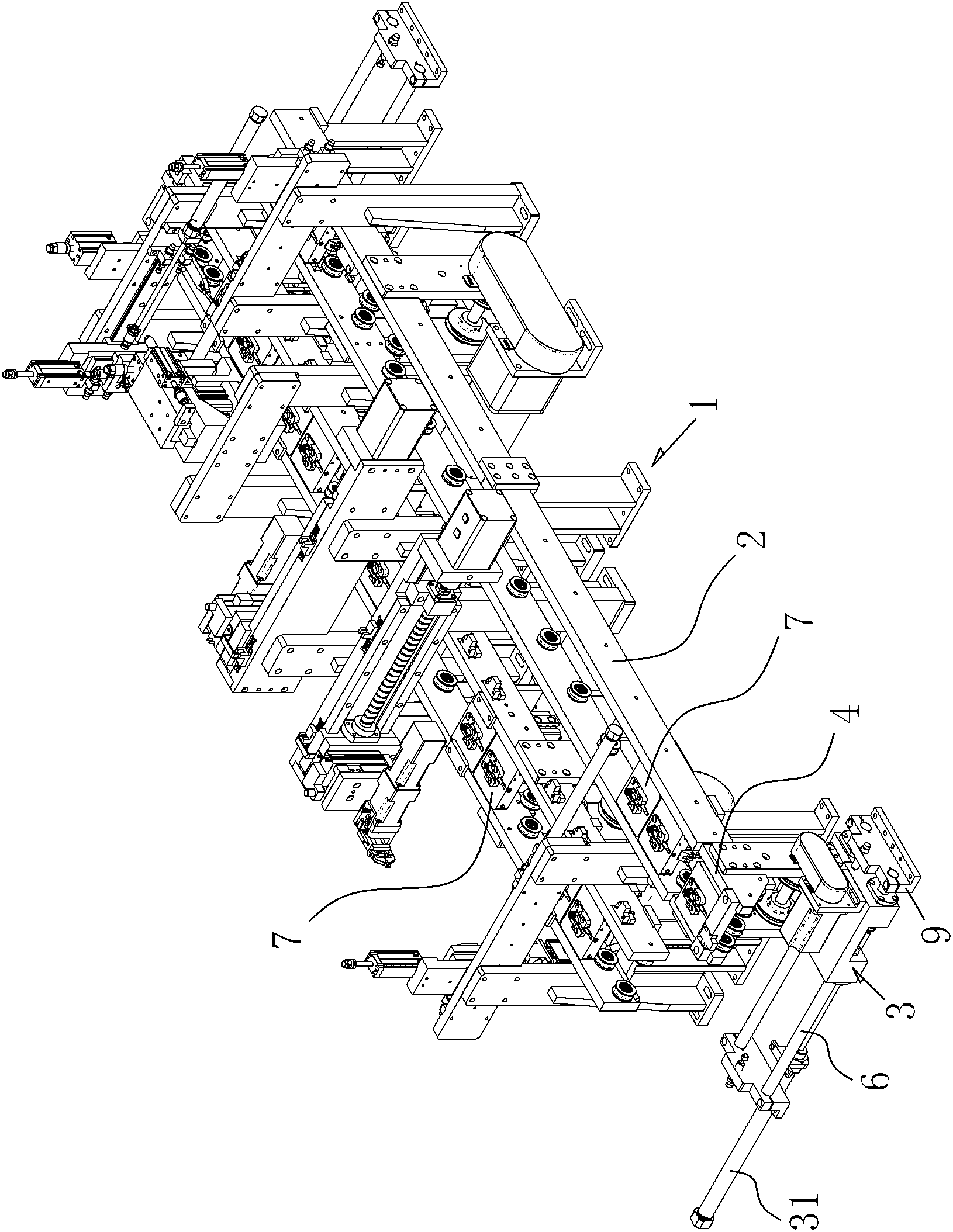

[0033] Below in conjunction with accompanying drawing, the present invention is further described:

[0034] see Figure 1-8 As shown, the transmission mechanism includes a base frame 1 as a carrier of the present invention, two equal-length, parallel transmission rails 2 are installed on the base frame 1, and a mold base 7 is placed in the transmission rail 2, and the mold base 7 advance along the transmission track 2. Wherein the transmission track 2 adopts a belt drive, that is, a transmission belt is arranged on both sides of the inner wall of the transmission track 2, and the mold base 7 is placed on the belt. When the belt is running, the friction force drives the mold base 7 to run.

[0035] Since the above two transmission tracks 2 are parallel to each other, an engaging mechanism is needed to form a circular transmission track. In the present invention, an engaging mechanism is respectively arranged at both ends of the two transmitting tracks 2, and one of them is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com